A coverstitch sewing machine is a precision instrument that embodies the essence of professional garment finishing.

This specialized sewing device is tailor-made for those seeking immaculate hems, polished seam closures, and decorative stitching on a variety of fabrics, particularly stretchy knits.

Unlike conventional sewing machines, a coverstitch machine utilizes multiple needles and loopers to create parallel rows of stitching on the fabric’s right side while simultaneously securing the threads beneath, producing sturdy and flexible hems and seams.

This tool’s unrivaled capacity to handle stretch fabrics with ease, differential feed for even fabric movement, and adjustable stitch width and length options make it an indispensable companion for both amateur and seasoned sewists striving for the highest standards in their creations.

What Is a Coverstitch Sewing Machine?

A coverstitch sewing machine is a specialized sewing machine designed for creating professional-looking hems and decorative stitches on various types of fabrics, particularly stretchy and knit fabrics like jersey, spandex, and Lycra.

This type of sewing machine is an essential tool for anyone who works with stretch fabrics or wants to achieve a polished and finished look in their sewing projects.

Here are the key features and functions of a coverstitch sewing machine:

Hemming

Coverstitch machines are unparalleled when it comes to creating clean and stretchable hems. The simultaneous use of two or three needles and loopers allows for the formation of a double or triple row of parallel stitches on the fabric’s right side.

Meanwhile, on the underside, a looper thread secures these stitches, resulting in a flexible and durable hem that can withstand the stretching and movement of the fabric. This feature is especially crucial for sewing activewear, swimwear, and other stretchy garments.

Decorative Stitching

In addition to practical hemming, coverstitch machines excel at decorative stitching.

By adjusting the width and length of the stitches and selecting the number of needles and loopers in use, you can create various decorative patterns, such as ladder stitching, flatlock seams, or even chainstitch-like designs.

These decorative stitches not only enhance the appearance of your projects but also add a touch of professionalism.

Seam Finishing

Coverstitch machines can serve as versatile tools for seam finishing. They effectively encase and secure raw fabric edges to prevent fraying.

This is particularly useful for lightweight and delicate fabrics, as it ensures neat and fray-free seams. It also eliminates the need for serging or overlocking the edges.

Elastic and Stretchy Fabric Handling

Coverstitch machines are specifically engineered to accommodate the unique challenges posed by stretchy and elastic fabrics.

The differential feed mechanism, along with the machine’s construction, ensures that the fabric is fed evenly and without distortion. This results in perfectly smooth and flexible seams and hems.

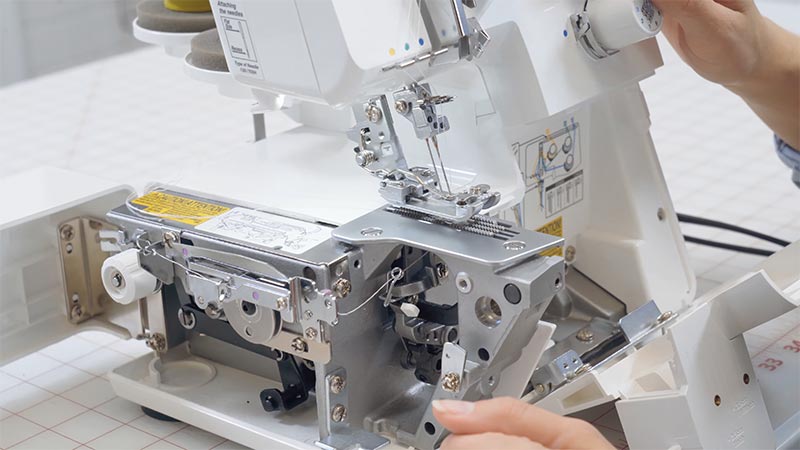

Multiple Needles and Loopers

The multiple needles and loopers are fundamental to the coverstitch’s operation. Two or three needles create parallel rows of stitching on the fabric’s right side, while the loopers secure the threads underneath.

The interaction of these components is what gives the coverstitch its characteristic look and functionality.

Differential Feed

Differential feed is a critical feature for controlling the movement of fabric layers, especially when dealing with stretch fabrics.

It allows you to adjust the feed dogs to move at different rates, preventing puckering on the top layer and stretching on the bottom layer. This is essential for achieving professional-looking results.

Adjustable Stitch Width and Length

The ability to adjust the stitch width and length on a coverstitch machine provides versatility. You can create different types of hems, decorative patterns, and seam finishes, depending on your project’s requirements.

For example, a wider stitch width is ideal for attaching fold-over elastic, while a narrower width is perfect for standard hems.

Free Arm or Flatbed

Some coverstitch machines come with a free arm, which is a removable extension table that allows you to work on cylindrical items like sleeves and pant legs more easily.

Others offer a flatbed configuration, which is useful for larger, flat projects. The choice between these configurations depends on the variety of sewing projects you plan to undertake.

Advantages of a Coverstitch Sewing Machine

A coverstitch sewing machine offers several distinct advantages, making it a valuable tool for sewists working with stretchy and knit fabrics or anyone seeking a professional finish for their sewing projects.

Here are some of the key advantages of using a coverstitch machine:

Perfect Hems

Coverstitch machines excel at creating flawless, stretchable hems on a wide range of garments, including T-shirts, leggings, and activewear.

The parallel rows of stitching and looper thread on the underside result in flat, elastic hems that can withstand the fabric’s stretch without breaking or puckering.

Professional Finish

The machine’s ability to produce parallel rows of stitches on the top side, with a secure looper thread beneath, gives your projects a polished, professional appearance. It’s the preferred choice for achieving a clean, ready-to-wear look in your clothing.

Versatile Decorative Stitches

Beyond hemming, coverstitch machines can be used for decorative topstitching. By adjusting the settings, you can create various decorative patterns, including ladder stitching, flatlock seams, and chainstitch-like designs. This adds a touch of sophistication to your sewing projects.

Seam Finishing

Coverstitch machines are excellent for finishing the raw edges of fabric, preventing fraying and ensuring clean, tidy seams on the inside of your garments.

This feature eliminates the need for additional seam finishing techniques, such as serging or overlocking.

Differential Feed

The differential feed mechanism allows you to control the movement of fabric layers independently. This is particularly useful when working with stretch fabrics, as it prevents distortion and puckering, ensuring that your seams and hems lie perfectly flat.

Multiple Needles and Loopers

The inclusion of two or three needles and loopers in coverstitch machines facilitates the formation of the characteristic coverstitch pattern.

These components work in tandem to create strong, flexible stitches that can withstand the demands of stretch fabrics.

Elastic Fabric Handling

Coverstitch machines are specifically designed to handle the unique challenges posed by stretchy and elastic fabrics.

They allow the fabric to stretch and move without compromising the integrity of the stitches, ensuring that your garments remain comfortable and durable.

Adjustable Stitch Width and Length

These machines offer flexibility with adjustable stitch width and length. You can customize the stitches according to your project’s requirements, from narrow, subtle hems to wider decorative topstitching.

Professional Results at Home

Coverstitch machines provide an opportunity for home sewists to achieve results comparable to those produced in commercial garment manufacturing.

The professional finish they offer is perfect for those who are passionate about sewing and aspire to create high-quality clothing and crafts.

Drawbacks of a Coverstitch Sewing Machine

While coverstitch sewing machines offer numerous benefits, they also have some drawbacks and limitations that users should be aware of.

Here are some of the key drawbacks of a coverstitch sewing machine:

Specialized Purpose

Coverstitch machines are designed for specific tasks, primarily creating hems, decorative stitches, and seam finishes on stretch fabrics.

They are not as versatile as regular sewing machines or sergers, which can handle a broader range of sewing tasks.

Cost

Coverstitch machines can be relatively expensive compared to standard sewing machines. This cost might be a barrier for hobbyist sewists or those with limited budgets.

Learning Curve

Using a coverstitch machine effectively can be challenging, especially for beginners. Setting up the machine, adjusting tensions, and mastering techniques for various fabrics can take time and practice.

Maintenance

Coverstitch machines often require more maintenance and care than basic sewing machines. Regular cleaning and oiling are essential to keep them running smoothly. Additionally, adjusting tensions and threading can be complex and time-consuming.

Limited Stitch Variations

While coverstitch machines excel at creating straight-line stitches, they have limited stitch options compared to regular sewing machines or sergers. They typically cannot produce zigzag or other decorative stitches.

Thicker Fabrics

Coverstitch machines may struggle with very thick or heavy fabrics. They are primarily designed for lightweight to medium-weight fabrics, so they may not be suitable for heavy denim or canvas projects.

Thread Management

Coverstitch machines use multiple threads, and thread management can be more complex than with a standard sewing machine.

Keeping track of thread tension and ensuring all threads are properly threaded is crucial for successful stitching.

Size and Weight

These machines can be relatively large and heavy, which can be a consideration if you have limited sewing space or need to transport your machine frequently.

Attachment Compatibility

Finding and installing compatible accessories or attachments for coverstitch machines can be more challenging than for standard sewing machines due to their specialized nature.

Noise and Vibration

Coverstitch machines can be noisier and produce more vibration compared to regular sewing machines, which might be a concern if you prefer a quieter sewing experience.

What Is a Coverstitch Sewing Machine Used For?

The coverstitch machine is often used in conjunction with a regular sewing machine and a serger to achieve a wide range of finishing techniques.

Here are some key uses of a coverstitch sewing machine:

Hemming

Coverstitch machines excel in creating flawless hems, making them an essential tool for anyone working with stretchy fabrics.

Whether you’re hemming the bottom of a T-shirt, the legs of yoga pants, or the sleeves of a knit dress, a coverstitch machine ensures the finished product looks neat and professional.

The coverstitch allows the fabric to stretch without the risk of the stitches breaking or popping, which is a common issue when using regular sewing machines.

Binding

Binding adds a polished and durable edge to various fabric applications, and coverstitch machines are adept at this task.

From finishing necklines on clothing to applying binding to the edges of blankets or even aprons, the coverstitch machine ensures that the binding lays flat and remains securely in place.

This feature is especially useful in producing clean, professional results on garments.

Decorative Stitching

Coverstitch machines offer a versatile range of decorative stitches, allowing sewists to add unique embellishments to their projects.

These decorative stitches can include elegant ladder stitches, attractive wave stitches, or other creative options, enabling you to personalize your creations with style and sophistication.

Seaming

In addition to hems and decorative work, coverstitch machines are proficient in creating sturdy, stretchy seams on knit fabrics.

This is particularly beneficial for sewing activewear, swimwear, and intimate apparel. The machine ensures that the seams are both durable and flexible, guaranteeing comfort and longevity in these specialized garments.

Elastic Application

Attaching elastic to garments, whether for waistbands or leg openings, is a common task in sewing. Coverstitch machines make this process straightforward.

They secure the elastic securely while allowing it to retain its stretch, which is essential for the comfort and functionality of items like sportswear and lingerie.

Frequently Asked Questions

Can I use a coverstitch machine for quilting?

No, coverstitch machines are not suitable for quilting, as they are designed for hems, decorative stitches, and seam finishes on stretch fabrics.

Are coverstitch machines suitable for heavy-duty fabrics like leather or canvas?

Coverstitch machines are generally not designed for heavy-duty fabrics. They work best on lightweight to medium-weight materials.

Do coverstitch machines come with built-in stitches or patterns?

No, coverstitch machines do not provide built-in decorative stitches or patterns like many regular sewing machines.

Can I use regular sewing machine thread in a coverstitch machine?

While it’s possible to use regular sewing machine thread in a coverstitch machine, it’s recommended to use specialty coverstitch thread.

Can I use a cover stitch machine for serging or overlocking seams?

Coverstitch machines are not intended for serging or overlocking raw fabric edges.

Wrap Up

A cover stitch sewing machine is an indispensable tool for sewists working with stretchy and knit fabrics, offering a range of unique advantages.

It excels in creating impeccable hems, professional finishes, and versatile decorative stitches.

The machine’s differential feed ensures even fabric movement, while its ability to handle elastic materials and provide secure, durable stitches sets it apart.

However, it’s essential to recognize its limitations, including the specialized purpose, cost, and maintenance requirements.

Nevertheless, for those passionate about crafting high-quality clothing and projects, a cover stitch machine represents a gateway to achieving the polished, professional results commonly seen in the garment industry. Its contribution to sewing excellence is undeniable.

Leave a Reply