A cylinder arm sewing machine is a specialized apparatus designed for precision in stitching tubular and cylindrical components, making it an indispensable tool in various industries.

Its distinctive cylindrical arm allows the fabric to be seamlessly wrapped around, facilitating the efficient sewing of sleeves, cuffs, collars, and other intricate garment elements.

This unique design also grants access to hard-to-reach areas, enabling meticulous stitching in confined spaces.

These machines are widely employed in garment manufacturing, tailoring, leatherwork, and upholstery and offer versatility, control, and efficiency.

Whether crafting clothing, leather goods, or upholstered items, the cylinder arm sewing machine enhances the quality and speed of production, making it a cornerstone in diverse sewing applications.

What Is a Cylinder Arm Sewing Machine?

A cylinder arm sewing machine is a specialized sewing apparatus distinguished by its cylindrical arm extending horizontally from the main body.

This design allows fabrics to be wrapped around the cylinder, facilitating the precise stitching of tubular or cylindrical items such as sleeves, cuffs, and collars.

The machine provides access to hard-to-reach areas, ideal for intricate garment details, ensuring meticulous sewing in confined spaces.

Widely used in garment manufacturing, leatherwork, and upholstery, the cylinder arm sewing machine enhances efficiency and versatility in various sewing applications, offering a valuable tool for professionals seeking precision in crafting tailored clothing and other cylindrical items.

Cylinder Arm Sewing Machine Uses

A cylinder arm sewing machine is designed for specific sewing tasks requiring maneuverability and accessibility to cylindrical or tubular objects.

Unlike flatbed sewing machines with a flat surface, cylinder arm machines feature a cylindrical arm extending outward from the machine’s main body.

This design allows the fabric or material to be wrapped around the cylinder, making sewing items such as sleeves, cuffs, collars, and other circular or tubular pieces easier.

Here are some key uses of cylinder arm sewing machines:

Sewing Tubular Items

Cylinder arm sewing machines excel in handling tubular items with their cylindrical arm design.

When sewing sleeves on garments, the fabric smoothly wraps around the cylinder, allowing for precise stitching.

This design ensures that the seam follows the natural curve of the sleeve, resulting in a professional and aesthetically pleasing finish.

This feature is particularly valuable in producing shirts, jackets, and dresses, where sleeve construction is a critical aspect of garment assembly.

Cuff and Collar Sewing

The meticulous sewing of cuffs and collars demands precision and control. Cylinder arm sewing machines provide an ideal solution for this task.

Operators can easily manipulate the fabric around the cylindrical arm, ensuring that the stitching aligns perfectly with the contours of cuffs and collars.

This capability is crucial for achieving the tailored and polished look expected in high-quality clothing.

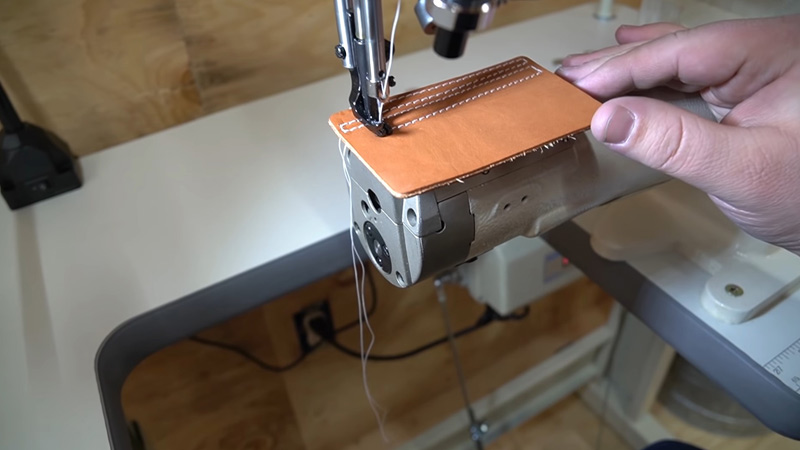

Leatherwork and Upholstery

The robust construction and ability to handle thick and heavy materials make cylinder arm sewing machines well-suited for leatherworking and upholstery projects.

Whether stitching leather garments, accessories, or upholstering furniture, these machines provide the power and precision to navigate through dense materials.

The cylindrical arm ensures smooth sewing on thick layers, contributing to the durability and longevity of the finished products.

Professional and Industrial Applications

Cylinder arm sewing machines are widely employed in professional and industrial settings where speed, precision, and reliability are paramount.

Garment manufacturers, tailors, and production facilities benefit from these machines’ efficiency in high-volume sewing operations.

The ability to consistently produce quality stitches on various materials positions these machines as essential tools in industries ranging from fashion to automotive upholstery.

Their durability and performance make them valuable assets in environments where sewing demands are intense and diverse.

Advantages of Using a Cylinder Arm Sewing Machine

Using a cylinder arm sewing machine offers several advantages, especially in sewing tasks involving tubular or cylindrical components.

Here are some key benefits of using a cylinder arm sewing machine:

Efficient Sewing of Tubular Items

One of the primary advantages of a cylinder arm sewing machine is its efficiency in sewing tubular items.

The cylindrical arm allows the fabric to be smoothly wrapped around it, providing a natural and unhindered path for stitching sleeves, pant legs, and other cylindrical garment elements.

This efficiency results in faster and more accurate sewing, especially in mass-production scenarios.

Precise Stitching in Hard-to-Reach Areas

The compact design of the cylinder arm sewing machine facilitates precise stitching in hard-to-reach areas.

Sewing inside pockets, along seam lines, or in tight corners becomes more accessible due to the cylindrical arm’s ability to navigate confined spaces.

This precision is crucial for achieving a polished and professional finish on intricate details of garments.

Versatility in Sewing Applications

Cylinder arm sewing machines are versatile tools that can handle various sewing tasks. Many models come with interchangeable components and attachments, allowing operators to switch between sewing techniques and projects.

This adaptability makes these machines suitable for various applications, from garment construction to leatherworking and upholstery.

Specialized for Cuff and Collar Sewing

These machines are particularly well-suited for sewing cuffs and collars. The cylindrical arm allows easy fabric manipulation around these intricate areas, ensuring precise stitching and a high-quality finish.

The specialized design of the machine caters to the specific requirements of tailoring and garment assembly, making it an essential tool in the apparel industry.

Handling Thick and Bulky Materials

Cylinder arm sewing machines are robust and can easily handle thick and bulky materials. This makes them ideal for working with leather, canvas, and heavy upholstery fabrics.

The machine’s powerful stitching capabilities contribute to the durability and longevity of sewn items in industries such as leathercraft, bag manufacturing, and furniture upholstery.

Increased Operator Control

The design of a cylinder arm sewing machine provides operators with increased control over the sewing process.

The ability to guide the fabric around the cylindrical arm allows for greater precision and attention to detail.

This is especially important when working on intricate designs or sewing delicate fabrics that require a delicate touch.

Time and Cost Efficiency

The efficiency and versatility of cylinder arm sewing machines contribute to time and cost savings in production environments.

The streamlined process of sewing tubular items and the ability to handle various materials and tasks enhance overall productivity.

This is particularly advantageous for businesses engaged in large-scale manufacturing where optimizing production speed and reducing costs are key considerations.

Disadvantages of Using a Cylinder Arm Sewing Machine

While cylinder arm sewing machines offer various advantages, they also come with certain disadvantages that should be considered:

Limited for Flat Sewing

The limitation in sewing flat pieces or larger fabric panels is notable when versatility is a priority.

For projects that predominantly involve flat surfaces or intricate quilting, a cylinder arm sewing machine may prove less efficient than flatbed machines’ broader capabilities.

This restriction can be decisive for individuals and industries with diverse sewing requirements.

Bulkier Design

The bulkier design of cylinder arm machines may pose challenges in workspaces where the available room is considered.

Compact studios or home sewing environments may find accommodating these machines more cumbersome.

This bulkiness can affect a sewing area’s overall layout and organization, potentially influencing the choice of machine based on spatial constraints.

Learning Curve

The steeper learning curve associated with operating a cylinder arm sewing machine is a factor that may impact the accessibility of these machines to certain users.

Those transitioning from flatbed machines may find it takes time to effectively develop the skills needed to manipulate fabric around the cylindrical arm.

This learning curve could lead to slower initial productivity until the operator becomes fully proficient.

Not Suitable for All Projects

While excelling at tubular sewing, cylinder arm machines may fall short in projects that require extensive flat sewing or quilting.

The specialized design that makes them efficient for sleeves and collars may become a limitation when tasked with projects outside their intended scope.

This makes it essential for users to assess whether their predominant sewing needs align with the strengths of a cylinder arm machine.

Cost

The higher upfront cost of cylinder arm sewing machines is a financial consideration that potential buyers must weigh against their specific needs and budget constraints.

While the specialized features justify the expense for certain applications, users with limited financial resources may opt for more affordable flatbed models that adequately meet their sewing requirements.

Maintenance Challenges

Maintenance challenges arise due to the intricate design of the cylindrical arm. Cleaning and servicing may require additional care and expertise compared to the relatively straightforward maintenance of flatbed machines.

This complexity could result in higher maintenance costs or the need for professional assistance, impacting the overall cost of ownership.

FAQs

Can a cylinder arm sewing machine handle flat sewing projects?

While its primary design caters to tubular items, a cylinder arm sewing machine may not be as convenient for flat sewing projects.

Its specialization in cylindrical components makes it less versatile for applications involving large fabric panels or intricate quilting.

Is there a learning curve for operating a cylinder arm sewing machine?

Yes, operating a cylinder arm sewing machine may have a steeper learning curve, especially for those accustomed to flatbed machines.

Are cylinder arm sewing machines suitable for quilting projects?

Cylinder arm sewing machines are not typically ideal for quilting projects.

Their specialized design for tubular items may limit their efficiency in handling the extensive flat sewing and intricate patterns often associated with quilting.

Last Words

A cylinder arm sewing machine is a specialized and invaluable tool in garment production and craftsmanship.

Tailored for sewing tubular items with precision, such as sleeves, cuffs, and collars, its distinctive cylindrical arm offers enhanced maneuverability and access to hard-to-reach areas.

While its advantages in specific applications are evident, it’s important to acknowledge the limitations, such as a learning curve, bulkier design, and a focus on cylindrical components.

As an indispensable asset in fashion and upholstery industries, the cylinder arm sewing machine balances efficiency and versatility, contributing to the creation of finely crafted garments and tailored items.

Leave a Reply