A drilling needle, a small yet indispensable accessory in the realm of sewing, serves as a remarkable tool for enhancing the artistry and functionality of various fabric-based creations.

This specialized sewing machine needle, characterized by its twin-needle configuration, is designed to create parallel rows of stitches with precision and finesse.

Whether you aspire to infuse decorative elegance into your projects, secure hems, quilt layers together, or reinforce seams, the drilling needle proves its versatility time and again.

With its adjustable stitch width, it enables artisans to craft customized designs, transforming simple fabric into a canvas of intricate patterns and textures.

In the world of sewing, the drilling needle stands as a testament to the endless possibilities of creativity and craftsmanship.

What Is a Drilling Needle on a Sewing Machine?

A drilling needle, also known as a twin or double needle, is a specialized sewing machine needle used in various sewing applications to create parallel rows of stitches simultaneously.

It is an essential tool for achieving a professional and decorative finish in many sewing projects.

The drilling needle consists of two needles mounted on a single shank, which allows the sewing machine to create two parallel lines of stitches in a single pass.

Here are some key functions of a drilling needle on a sewing machine:

Needle Configuration

A drilling needle is unique because it comprises two-needle shafts attached to a single shank. These needle shafts may have the same size or different sizes.

When installed correctly, they align perfectly with the sewing machine’s presser foot, allowing for precise stitching.

Stitch Width

The distance between the two needles on a drilling needle is adjustable, offering flexibility in creating various widths of double rows of stitches.

This adjustability is a valuable feature, especially when you want to customize your sewing projects to achieve different decorative effects.

Decorative Stitching

The primary purpose of a drilling needle is decorative stitching. It enables you to produce intricate and eye-catching designs on your fabric.

From parallel lines to intricate patterns, you can use this needle to add a touch of elegance and sophistication to your sewing projects.

Hemming

When it comes to hemming, drilling needles are indispensable. They make it easy to create professional-looking hems that are not only visually appealing but also sturdy.

Whether you’re working with lightweight or heavyweight fabrics, a drilling needle helps prevent fraying and ensures a clean finish.

Quilting

Quilters often turn to drilling needles for quilting projects. This needle type allows you to create evenly spaced lines of stitching that enhance the appearance of your quilt while securing the layers of fabric and batting together. The result is both functional and aesthetically pleasing.

Stretch Fabrics

Stretchy fabrics like jersey knits and spandex can be challenging to work with. Drilling needles come to the rescue by providing twin rows of stitches that prevent the fabric from losing its shape over time. This is particularly important for activewear and stretchy garments.

Topstitching

When you need to reinforce seams or create a polished edge, a drilling needle is your best friend. Topstitching is a technique often used in sewing to add strength and structure to various parts of a garment, such as collars, cuffs, and waistbands.

Pintucks

Pintucks are tiny, evenly spaced folds in fabric that are stitched down. Drilling needles excel at creating these delicate details, which are commonly used in heirloom sewing, fine lingerie, and special occasion garments.

Pintucks add texture and dimension to your creations, making them truly unique.

Types of Drilling Needles on Sewing Machines

In sewing, needles are an essential component, and they come in various types to accommodate different fabrics and sewing tasks.

Here are some common types of sewing machine needles:

Universal Needles

Universal needles are incredibly versatile and are the go-to choice for most general sewing tasks. They come in various sizes and have a slightly rounded point.

These needles can work effectively with both woven and knit fabrics, making them suitable for everyday sewing projects such as sewing garments, home decor, and alterations.

Their ability to handle a range of fabric types makes them a staple in any sewing kit.

Ballpoint Needles

Ballpoint or jersey needles are specially designed for knit fabrics like jersey, interlock, and other stretch materials.

They have a rounded tip, which allows them to slide between the knit fibers rather than piercing them. This prevents snags, runs, or damage to the fabric.

Ballpoint needles are perfect for sewing T-shirts, knitwear, and any stretchy fabrics, ensuring smooth and even stitching.

Sharp Needles

Also known as Microtex needles, sharp needles are characterized by their very fine, sharp point.

These needles are ideal for working with delicate and lightweight fabrics such as silk, chiffon, tulle, and fine linens.

The fine point creates precise stitches and reduces the risk of fabric damage or puckering. Sharp needles are a must for intricate sewing projects that require precision.

Jeans Needles

Jeans or denim needles are engineered for heavyweight fabrics like denim, canvas, and upholstery materials.

They have a strong, thick shaft and a sharp point that can easily penetrate and stitch through multiple layers of dense fabric.

These needles are essential when working on projects like jeans, heavy jackets, or home upholstery, where standard needles might break or struggle to sew smoothly.

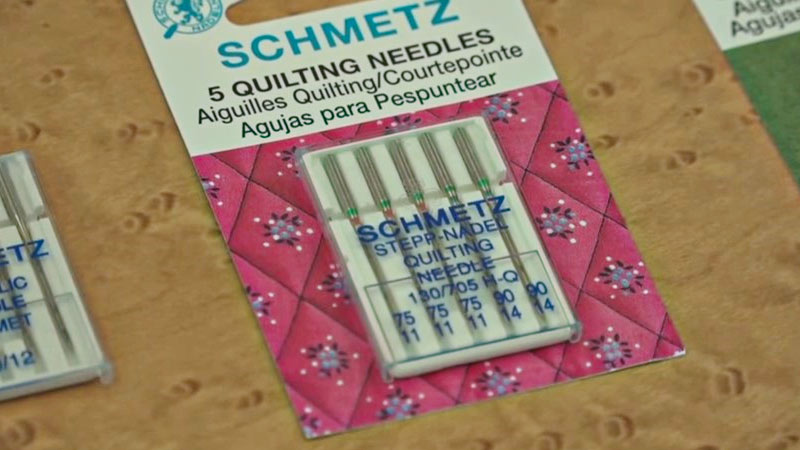

Quilting Needles

Quilting needles feature a tapered point, which makes them ideal for quilting projects. They can effortlessly penetrate through multiple layers of fabric and batting, creating even stitches.

Quilting needles are designed to reduce fabric distortion and help quilters achieve precise and professional results. They’re a must-have for anyone engaged in quilting and patchwork projects.

Embroidery Needles

Embroidery needles are specially designed for decorative stitching and embroidery work. They feature a larger eye to accommodate thicker embroidery threads, making it easier to thread them through.

These needles come in various sizes to suit different thread thicknesses. Embroidery needles are perfect for adding intricate and decorative designs to various fabrics, including cotton, silk, and even heavier materials.

Topstitch Needles

Topstitch needles are known for their extra-large eye and a deep groove on the front side of the needle. These features make them ideal for creating prominent topstitching lines on fabrics.

They are commonly used when you want the stitching to be visible and decorative, such as on the hems, cuffs, and seams of garments.

Topstitch needles can handle thicker topstitching threads and provide a professional finish.

Stretch Needles

Stretch needles are specifically designed to work with highly elastic and stretchy fabrics like Lycra, Spandex, and other knits.

They have a unique construction with a medium ballpoint tip that prevents skipped stitches and fabric damage.

Stretch needles are essential for sewing activewear, swimwear, lingerie, and any project where the fabric has significant stretch.

Leather Needles

Leather needles, also called leather sewing machine needles, have a chisel-point tip that makes them perfect for sewing leather, suede, and other thick, non-woven materials.

These needles can easily penetrate and stitch through heavy materials, creating durable and secure seams.

They are essential for leathercraft projects, including making leather bags, belts, and jackets.

Twin or Double Needles

Twin or double needles consist of two needles mounted on a single shank. They are used for creating parallel rows of stitching, often for decorative purposes or hemming garments.

These needles are available in various widths, allowing you to achieve different spacings between the rows of stitches.

Twin needles are commonly used for creating professional-looking hems on garments, as well as decorative topstitching.

Wing Needles

Wing needles are unique in design, featuring wings on each side of the needle shaft. These wings help create openwork and decorative effects when used with lightweight fabrics, particularly woven fabrics like cotton or linen.

When the wing needle pierces the fabric, it pushes aside the fibers, creating openings and designs in the process.

Wing needles are often used for heirloom sewing, embellishing, and adding delicate decorative touches to various projects.

Hemstitch or Wing-Cut Needles

Hemstitch or wing-cut needles are versatile tools used to create beautiful hemstitching and cut-out designs in fabrics. One side of the needle features a wing, while the other side has a sharp blade.

When sewing with a hemstitch needle, the wing side produces small openings or eyelets in the fabric, while the blade side trims away excess fabric, resulting in a precise and decorative hemstitch effect.

These needles are commonly used for heirloom sewing, as well as for crafting intricate cut-out designs in lightweight fabrics.

Serger Needles

Serger needles are designed specifically for serger or overlock machines, which are used for finishing raw edges and creating professional-quality seams on fabrics.

Serger needles come in various sizes and types to accommodate different serging tasks and fabric types.

Common types of serger needles include universal, stretch, and specialty needles designed for specific materials like denim or knit fabrics.

Selecting the right serger needle ensures clean and secure serged edges, preventing fraying and unraveling.

How to Insert Needle in Sewing Machine?

Inserting a needle into a sewing machine is a fundamental step in preparing your machine for sewing.

Here are the steps to properly insert a needle into a sewing machine:

Tools Needed:

- Sewing machine

- Appropriate sewing machine needle for your fabric and project

- A screwdriver (if required)

Steps:

Prepare Your Work Area

Ensure your sewing machine is turned off and unplugged for safety. Also, make sure you have adequate lighting to see what you’re doing.

Choose the Right Needle

Select a sewing machine needle that is appropriate for your project and fabric type. Different needles are designed for various fabrics, such as universal, ballpoint (for knits), denim, leather, and more. The needle packaging or your sewing machine’s manual will guide you in selecting the correct needle.

Remove the Old Needle

If there is an old needle in your machine, you’ll need to remove it. Most machines have a needle clamp or screw that holds the needle in place.

Use a screwdriver to loosen the needle clamp, and carefully slide out the old needle. Dispose of the old needle properly.

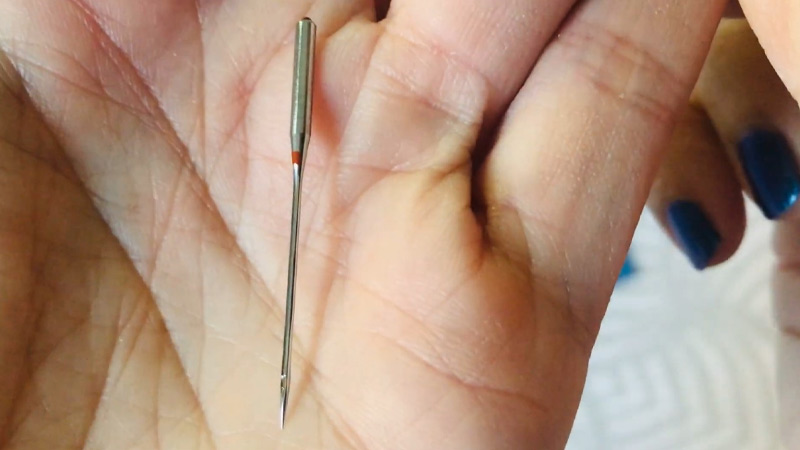

Inspect the Needle

Before inserting the new needle, inspect it for any damage or bends. A damaged needle can cause stitching issues and fabric damage. Replace it if necessary.

Insert the New Needle

Hold the new needle with the flat side toward the back of the machine. Depending on your machine’s design, you may need to push the needle up into the needle clamp and tighten the needle clamp screw securely.

Alternatively, some machines have a built-in needle threader that helps guide the needle into place.

Needle Position

Ensure the needle is inserted as far up as it can go while still being held securely by the needle clamp. This ensures the needle is in the correct position for stitching.

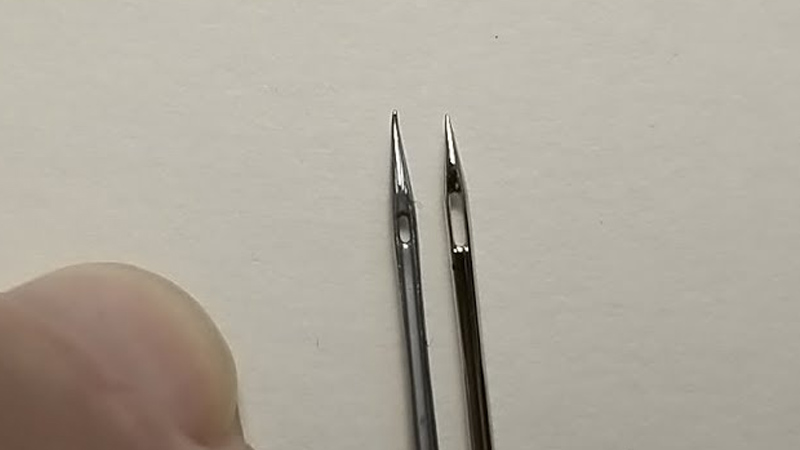

Check Needle Alignment

Double-check that the needle is correctly aligned. The groove on the needle should be facing the front of the machine, and the flat side should be facing the back. Proper alignment is crucial for consistent stitching.

Tighten the Needle Clamp

If your machine has a needle clamp screw, use a screwdriver to tighten it securely but not excessively. Over-tightening can cause damage to the needle or the machine.

Threading the Needle

After inserting the needle, thread it according to your sewing machine’s threading instructions. Typically, the thread goes from the spool, through a series of guides, through the needle’s eye, and then down to the bobbin area.

Test Your Machine

Before starting your project, do a test run on scrap fabric to ensure the needle is inserted correctly, and your machine is stitching smoothly.

How to Choose the Appropriate Sewing Machine Needle?

Choosing the appropriate sewing machine needle is crucial for achieving the best results in your sewing projects.

The right needle ensures smooth stitching, prevents fabric damage, and helps you overcome sewing challenges associated with different fabrics and techniques.

Here’s a step-by-step guide on how to choose the right sewing machine needle:

Identify Your Fabric

Start by identifying the type of fabric you’ll be working with. Consider factors such as fabric weight, fiber content, and weave.

Common fabric categories include woven, knit, heavy, lightweight, and specialty fabrics like leather or silk.

Understand Needle Sizes

Sewing machine needles come in various sizes, typically identified by two numbers (e.g., 80/12 or 90/14).

The first number indicates the European size (e.g., 80) and the second number represents the American size (e.g., 12).

Smaller numbers indicate finer needles, while larger numbers signify thicker needles. Choose the needle size based on your fabric’s weight.

Light fabrics like chiffon may require a smaller needle (70/10 or 80/12), while heavy denim might need a larger one (100/16 or 110/18).

Select the Needle Type

Choose a needle type that matches your fabric and sewing technique:

- Universal Needles: Ideal for general sewing on both woven and knit fabrics.

- Ballpoint or Jersey Needles: Designed for knit fabrics to prevent snags and runs.

- Sharp or Microtex Needles: Best for lightweight and delicate fabrics like silk and tulle.

- Jeans or Denim Needles: For heavyweight fabrics like denim and canvas.

- Quilting Needles: Suitable for quilting projects with multiple fabric layers.

- Embroidery Needles: Designed for decorative stitching with embroidery threads.

- Leather Needles: Essential for sewing leather, suede, and other heavy materials.

- Stretch Needles: Specifically for highly elastic and stretchy fabrics.

- Topstitch Needles: Create prominent topstitching lines on fabrics.

- Twin or Double Needles: For parallel rows of stitching, often for hems or decorative purposes.

- Wing Needles: Produce openwork and decorative effects on lightweight fabrics.

- Hemstitch or Wing-Cut Needles: Used for hemstitching and cut-out designs.

- Serger Needles: Designed for overlock machines, with types for different tasks and fabrics.

Consider Specialty Needs

If you’re working on unique or challenging projects, such as heirloom sewing, consider specialty needles like wing needles, wing-cut needles, or any other that meets your specific requirements.

Test on Scrap Fabric

Before starting your project, test the selected needle on a scrap piece of the same fabric. This allows you to check for stitch quality, tension adjustments, and any potential issues before sewing your main project.

Change Needles Regularly

Sewing machine needles can become dull or damaged over time. Replace the needle after every 8-10 hours of sewing or when you notice decreased stitch quality, skipped stitches, or fabric damage.

How to Care For Your Drilling Needles?

Caring for your drilling needles, also known as drill bits, is essential to ensure they remain sharp, effective, and safe to use.

Proper maintenance can extend their lifespan and improve the quality of your drilling work.

Here’s how to care for your drilling needles:

Cleaning

After each drilling session, it’s essential to clean your drill bits thoroughly. Use a stiff brush, like a wire brush or a toothbrush, to remove any chips, dust, or debris that may have accumulated on the bit’s surface. Ensure that the entire bit is clean, as even small particles can affect its performance.

Inspection

Regular inspection of your drill bits is crucial to identify any signs of wear or damage. Look closely at the cutting edges for chips or nicks, and check the overall condition of the bit.

If you notice any issues, consider repairing or replacing the drill bit to maintain its effectiveness.

Sharpening

Dull drill bits can lead to inefficient drilling and increased effort. To maintain their sharpness, you can use a specialized drill bit sharpening tool or a bench grinder with a fine-grit wheel.

Follow the manufacturer’s instructions carefully to ensure proper sharpening. Remember that improper sharpening can worsen the bit’s performance, so take your time and do it correctly.

Storage

Proper storage is essential to prevent your drill bits from rusting or corroding. Store them in a dry, clean location away from moisture and humidity.

You can use a dedicated drill bit case, organizer, or a pegboard to keep them organized and separate, preventing them from knocking against each other and causing damage.

Proper Technique

Using the right drilling techniques is key to prolonging the life of your drill bits. Avoid excessive force or pressure when drilling, as this can lead to overheating and premature wear. Instead, let the bit do the work and maintain a steady hand as you operate your drill.

Size and Material Compatibility

Select the appropriate drill bit size and material type for your specific drilling task. Using the wrong bit can result in inefficient drilling, damage to the material, or even the drill bit itself. Double-check your bit selection before starting any drilling project.

Coolant or Lubrication

Depending on the material you’re drilling into, it may be beneficial to use a coolant or lubricant. These substances reduce friction and heat, which can help extend the life of your drill bits and improve drilling efficiency.

Be sure to use the right type of coolant or lubricant for the material you’re working with.

Replace When Necessary

Despite proper care, drill bits will eventually wear out over time. If you notice a significant decrease in performance or if a bit is damaged beyond repair (such as with a severely chipped or bent shaft), replace it promptly to ensure safe and efficient drilling.

Safety

Always prioritize safety when working with drilling needles. Wear appropriate personal protective equipment (PPE), including safety glasses or goggles, hearing protection, and dust masks if needed. Safety should be a top concern when operating power tools and handling drill bits.

FAQS

Can drilling needles be used for regular sewing tasks?

Drilling needles, if referring to specialty needles, are typically designed for specific decorative purposes and may not be suitable for standard sewing tasks.

Are drilling needles compatible with all sewing machines?

Compatibility may vary depending on the sewing machine model and needle type. Some machines may require additional attachments or adjustments to accommodate specialized needles like wing needles.

Can beginners use drilling needles effectively?

Beginners can use drilling needles effectively after gaining experience with standard sewing techniques.

How a drill machine needle is different from regular sewing needles?

A drill machine needle, also known as a drill-eyed needle, features a unique, larger eye compared to standard sewing needles.

What does “drills and needles” mean in the context of sewing?

Drills and needles meaning the combination of using drilling or cut-out needle techniques alongside regular sewing needles.

What is twin needle tunneling?

Twin needle tunneling occurs when two parallel rows of stitching sink into the fabric, creating a visible groove or tunnel.

What are drill-eyed needles?

Drill-eyed needles are a kind of needles that have a larger eye compared to standard sewing needles.

To Recap

A drilling needle on a sewing machine is a critical component that aids in creating decorative and functional effects on various fabrics.

While not a conventional term in sewing, it may refer to a specialized needle, such as a wing or wing-cut needle, designed for crafting intricate cut-out designs and decorative stitching.

The choice of the right sewing machine needle, whether standard or specialized, is pivotal in achieving optimal results in sewing projects.

By selecting the appropriate needle based on the fabric type and desired effect, sewers can ensure smooth, precise stitching and elevate the quality and creativity of their creations.

Understanding and using the right needles is fundamental in the world of sewing craftsmanship.

Leave a Reply