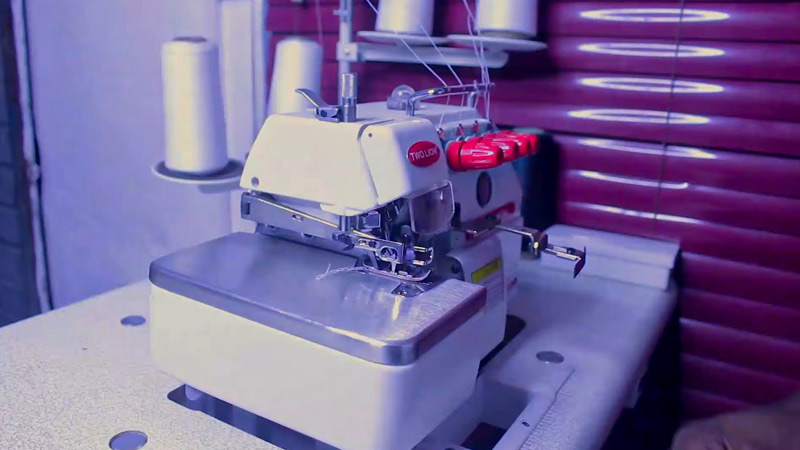

A four-thread sewing machine, commonly known as a serger or overlocker, is a specialized apparatus in garment construction.

Distinguished by its capability to simultaneously use four threads, this machine offers many functions beyond the scope of a conventional sewing device.

Primarily employed for efficient seam finishing and constructing robust seams, the four-thread serger prevents fraying and enhances fabric edges’ durability.

With the ability to create professional-looking hems, handle stretch fabrics, and produce a variety of stitches, it has become an indispensable tool for sewists seeking precision, speed, and versatility in their projects.

What Is a Four-Thread Sewing Machine? Key Features

A four-thread sewing machine is a versatile and efficient tool used in garment construction to create solid and professional-grade seams.

Unlike more straightforward machines, a four-thread machine utilizes two threads on the needle and two on the looper, enabling it to produce secure overlock stitches that prevent fabric fraying and ensure a clean finish.

The machine’s configuration allows for a balanced and sturdy seam that withstands wear and tear, making it particularly useful for sewing knits and stretch fabrics.

Typically equipped with double straight needles and double curved needles, the four-thread sewing machine excels in edging, seaming, and hemming tasks.

This combination of needles and threads enhances the machine’s capability to handle a variety of fabrics, including those with stretch and elasticity.

Sewing enthusiasts and professionals often turn to the four-thread machine for its ability to create durable and neat seams, making it an indispensable tool in garment construction and textile work.

Here are the key features of a four-thread sewing machine:

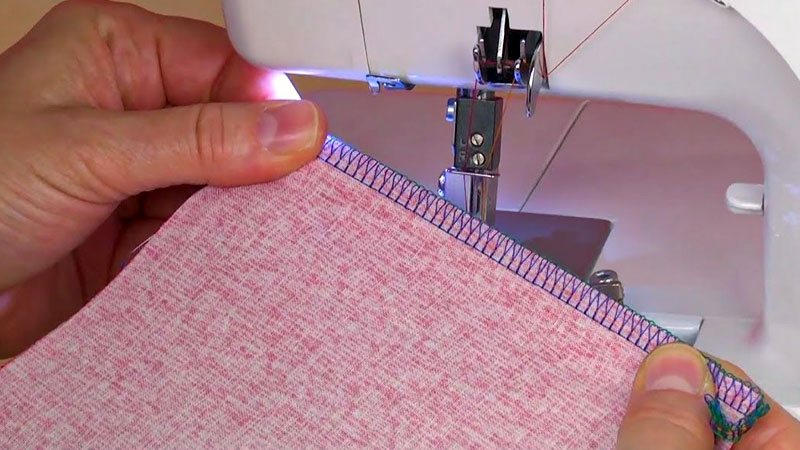

Efficient Seam Finishing

A four-thread serger’s efficiency in seam finishing is a game-changer. Not only does it trim excess fabric seamlessly, it also creates an overlock stitch that is a robust barrier against fraying.

This meticulous finishing not only elevates the aesthetic quality of the project but also ensures that fabric edges remain intact over time.

The polished look achieved by the serger adds a professional touch, making it an indispensable tool for sewists who prioritize precision and durability in their creations.

Robust Seam Construction

The four-thread serger excels in constructing seams with unmatched strength and durability. Its ability to utilize the standard overlock stitch significantly reinforces seams, making it an ideal choice for garment assembly.

Whether working with heavy fabrics or delicate materials, the serger ensures that seams withstand the rigors of wear and tear, contributing to the longevity of the finished garment.

Professional-Looking Hems

A standout feature of the four-thread serger is its proficiency in creating professional-looking hems.

The machine’s capability to produce neat and compact rolled hems is particularly beneficial for lightweight fabrics.

This feature prevents the bulkiness often associated with traditional hems and adds a refined and polished finish to garment hemlines, making it a preferred choice for projects that demand a high level of craftsmanship.

Versatile Stitching Options

Four-thread sergers offer many stitching options, extending beyond the standard overlock stitch.

With the ability to create decorative and flatlock stitches, these machines provide sewists with a versatile toolkit for unleashing their creative potential.

The variety of stitches allows for customization and personalization, making the serger an essential companion for those looking to add unique embellishments and details to their projects.

Handling Stretch Fabrics

Sergers, particularly the four-thread variety, are experts in handling stretch fabrics. This capability is crucial for sewing activewear, swimwear, and other garments requiring elasticity.

The serger’s flexible seams move seamlessly with the fabric, preventing breakage and ensuring optimal comfort for the wearer.

This feature is a testament to the machine’s adaptability to various fabric types and its importance in modern sewing.

Time-Saving Efficiency

Renowned for its time-saving efficiency, the four-thread serger streamlines the sewing process. The ability to sew, trim, and finish edges in a single pass significantly reduces the time spent on each project.

This time efficiency is particularly advantageous in production settings or when working on projects with tight deadlines, allowing sewists to accomplish more without compromising on the quality of their work.

Reduction of Bulk

The four-thread serger’s overlock stitch functionality goes beyond seam reinforcement; it actively trims seam allowances as it sews, effectively reducing bulk.

This feature is particularly advantageous in multi-layered projects where excess fabric could lead to unsightly thickness.

The serger’s ability to create smoother finishes enhances the overall appearance of garments, ensuring a polished and professional look, even in intricate or densely layered creations.

Convertible Functionality

The adaptability of some four-thread sergers is a standout feature. Specific models can be easily converted into a three-thread machine, making them versatile tools for various applications.

This convertible functionality especially benefits lighter projects, providing stitch options and thread configuration flexibility.

It allows sewists to seamlessly transition between different sewing needs without needing multiple machines.

Thread Tension Control

Four-thread sergers typically offer adjustable thread tension, putting control in the hands of the user.

This feature is invaluable when working with different fabrics, ensuring that the stitches are perfectly balanced and achieve the desired quality.

The ability to fine-tune thread tension allows optimal performance across various materials, contributing to the machine’s versatility.

Knife and Stitch Width Adjustability

Equipped with a cutting knife, the four-thread serger doesn’t just sew; it trims fabric during the sewing process. This built-in knife ensures precise cutting, contributing to the reduction of bulk in seams.

Additionally, adjustable stitch width adds another layer of customization, allowing sewists to tailor their stitches based on specific project requirements. These features empower users to achieve tailored results with precision and ease.

Professional Finishing Touch

A hallmark of the four-thread serger is its ability to impart a professional finishing touch to sewing projects. This characteristic has made it a staple in home sewing and industrial settings.

The machine’s ability to consistently produce high-quality, neatly finished seams elevates the overall craftsmanship of garments.

This professional touch not only enhances the final product’s appearance but also contributes to the durability and longevity of the sewn items, establishing the serger as a reliable tool for achieving professional-grade results.

Uses of a 4-Thread Sewing Machine

A 4-thread sewing machine is commonly used in sewing projects to create secure and professional-looking seams, hems, and finishes.

The four threads in a serger typically consist of two needles and two loopers, which work together to trim, stitch, and overcast fabric edges simultaneously.

Here are the uses of a 4-thread sewing machine:

Seam Finishing

The seam finishing capability of a 4-thread serger is indispensable for preventing fabric edges from unraveling.

As the machine stitches, it simultaneously trims excess fabric, creating a clean and polished overlock stitch. This enhances the aesthetic appeal of the garment and adds durability to the seams.

The overlock stitch acts as a barrier, significantly reducing the risk of fraying, especially in woven fabrics prone to unraveling.

This function ensures that the finished project maintains a professional appearance while increasing the garment’s longevity.

Seam Construction

In seam construction, the 4-thread serger showcases its versatility by offering a variety of stitches, with the standard overlock stitch being a staple.

This stitch not only secures the edges but also reinforces the seam, contributing to the overall strength and durability of the garment.

Whether working on heavy denim or delicate fabrics, the 4-thread serger provides consistent and reliable results, making it an excellent choice for constructing a wide range of garments and fabric items.

Professional-Looking Hems

The ability to create professional-looking rolled hems sets the 4-thread serger apart. This feature is particularly advantageous when working with lightweight fabrics, where traditional hems might result in bulkiness.

The serger’s rolled hem function produces neat and compact hems, elevating the finished look of garments.

This is especially beneficial for projects that demand a refined and polished appearance, such as eveningwear or tailored pieces.

Decorative Edges

Beyond its functional aspects, the 4-thread serger is a creative tool for decorative stitching.

By experimenting with different thread colors or incorporating specialty threads, sewists can add unique and eye-catching embellishments to their projects.

This feature allows for personalization and customization, making the serger a versatile machine for both functional and aesthetic aspects of garment construction.

Stretch Fabrics

The 4-thread serger excels in handling stretch fabrics commonly used in activewear, swimwear, and other garments requiring elasticity.

Its ability to create flexible seams that move with the fabric is crucial in preventing breakage and ensuring comfort for the wearer.

This makes the serger an essential tool for projects where maintaining the integrity of stretch fabrics is paramount.

Time-Saving

Sergers are renowned for their efficiency, and the 4-thread serger is no exception. Its ability to sew, trim, and finish edges in a single pass translates to significant time savings, especially compared to the multiple steps required with traditional sewing machines.

This time efficiency is particularly beneficial in mass production settings or when faced with tight project deadlines, allowing sewists to streamline their workflow without compromising quality.

Versatility

The versatility of some 4-thread sergers is enhanced by their ability to be converted into a 3-thread machine for more lightweight applications.

This flexibility in stitch options and thread configurations ensures that the serger can adapt to various sewing tasks.

Whether working on heavy-duty projects or delicate fabrics, the serger’s adaptability makes it a valuable tool for sewists with diverse creative pursuits.

Advantages of Using a Four-Thread Sewing Machine

A four-thread sewing machine, commonly known as a serger or overlocker, offers several advantages that make it a valuable tool in sewing and garment construction.

Here are the key advantages of using a four-thread sewing machine:

Efficient Seam Finishing

The efficiency in seam finishing with a four-thread serger cannot be overstated. Unlike traditional sewing machines that may require separate steps for cutting and finishing edges, a serger trims excess fabric and encases the raw edges in one swift motion.

This saves time and ensures a neat and professional appearance, making it an invaluable tool for projects with multiple seams or when working with fabrics prone to fraying.

Strong and Durable Seams

Four-thread sergers contribute to the structural integrity of garments by creating solid and durable seams.

The overlock stitch produced by these machines secures the edges and reinforces the seam, making it resilient to wear and tear.

This is especially important for garments subjected to frequent movement or stress, ensuring they withstand the test of time.

Professional-Looking Hems

The ability to produce professional-looking rolled hems is a distinctive feature of many four-thread sergers.

This is particularly advantageous for lightweight fabrics where traditional hems might appear bulky.

The serger’s rolled hem function creates a narrow, elegant edge, elevating the overall quality and appearance of the garment. It is a sought-after detail for projects requiring a refined and polished finish.

Versatility in Stitching

Four-thread sergers offer a wide range of stitch options, expanding the creative possibilities for sewists.

In addition to the standard overlock stitch, these machines can often create decorative stitches, flatlock stitches, and more.

This versatility allows for customization and personalization, making it an ideal tool for those who want to explore various stitch patterns and embellishments in their projects.

Handling Stretch Fabrics

The four-thread serger’s capability to handle stretch fabrics is a game-changer in garment construction.

Whether working with spandex, knits, or other stretch materials, the serger creates flexible seams that move seamlessly with the fabric.

This ensures the material’s elasticity is preserved, preventing seam breakage and guaranteeing comfort in garments designed for active wear or items requiring stretch and recovery.

Time-Saving in Production

Time efficiency is a hallmark of sergers, and the four-thread variety saves valuable production time.

With the ability to sew, trim, and finish edges in a single pass, these machines are particularly beneficial in industrial settings or for sewists tackling projects with tight deadlines.

The streamlined process allows for increased productivity without compromising the quality of the finished product.

Reduction of Bulk in Seams

The overlock stitch produced by a four-thread serger trims seam allowances as it sews, reducing bulk in the seams.

This is especially advantageous when working with heavyweight fabrics or when multiple layers are involved in a project.

The result is a smooth and even finish that enhances the overall appearance and comfort of the garment.

Professional Finishing for Home Sewing

While often associated with professional garment production, four-thread sergers have become increasingly popular among home sewists. These machines bring expertise and a polished finish to home-sewn projects.

Whether creating everyday garments or special occasion wear, the serger elevates the quality of homemade items, allowing individuals to achieve professional results in the comfort of their own sewing spaces.

FAQs

How does a four-thread serger reduce bulk in seams?

The overlock stitch produced by a four-thread serger trims seam allowances as it sews, effectively reducing bulk.

Can a four-thread serger handle stretch fabrics?

Yes, four-thread sergers are well-suited for sewing stretch fabrics.

They create flexible seams that move with the fabric, preventing breakage and ensuring comfort, making them ideal for activewear and other stretchy garments.

Why is thread tension control necessary in a four-thread serger?

Thread tension control is crucial in achieving the desired fabric stitch quality.

Adjustable thread tension allows users to fine-tune the machine’s performance, ensuring optimal stitching results across various materials.

Wrap Up

A four-thread sewing machine, or serger, emerges as a versatile and indispensable tool in the realm of garment construction.

With its ability to efficiently finish seams, construct robust stitches, create professional-looking hems, and handle various fabrics, the serger has revolutionized the sewing landscape.

Its versatility extends to handling stretch fabrics, offering time-saving efficiency, reducing bulk in seams, and providing convertible functionalities.

Equipped with features like thread tension control, knife and stitch width adjustability, and a distinctive professional finishing touch, the four-thread serger caters to the needs of both home sewists and industrial settings, empowering users to achieve precise, durable, and polished results in their sewing endeavors.

Leave a Reply