A lapped seam is a versatile stitching technique to join two fabric pieces securely. This method overlaps one fabric edge, creating a neat and reinforced connection.

Lapped seams find widespread application due to their ability to provide strength, durability, and a polished finish to various garments and textile projects.

Suitable for lightweight and heavier fabrics, this sewing approach is a staple in creating resilient seams.

Understanding the fundamentals of a lapped seam empowers sewers to choose the appropriate technique for their projects, contributing to the overall quality and longevity of the finished creations.

What Is a Lapped Seam in Sewing?

A lapped seam is a sewing technique that involves overlapping and securing two fabric edges with stitches.

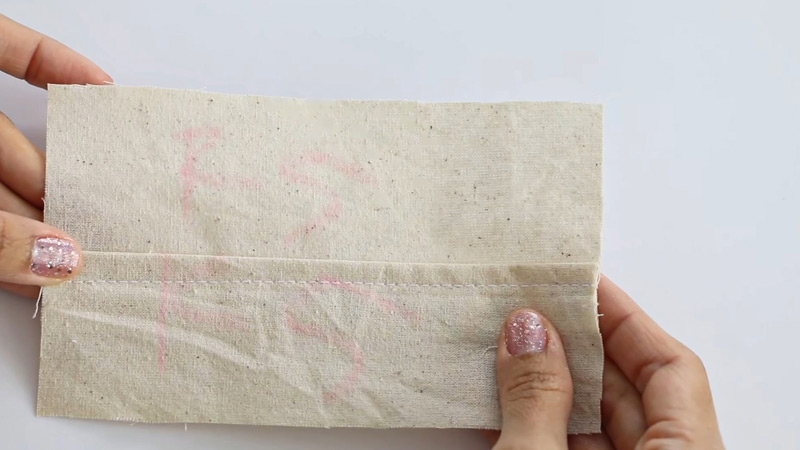

This method is commonly used in garment construction to create strong, durable, neat seams. To make a lapped seam, one fabric edge is folded over the other, and the folded edge is then stitched in place.

This overlapping design helps prevent fraying and adds strength to the seam, making it suitable for various fabrics.

Lapped seams are often used in tailored garments and are particularly useful when working with fabrics that tend to unravel quickly.

The seam provides a clean finish on the inside and outside of the garment, enhancing its overall appearance.

This versatile sewing technique can be applied to different garment elements, such as sleeves, side seams, or even decorative features.

Overall, lapped seams contribute to a well-constructed garment’s professional and polished look.

Lapped Seam Uses

A lapped seam is used in sewing and textile construction where two fabric pieces overlap and are stitched together.

This technique is widely employed in various applications due to its versatility and durability. Lapped seams are particularly useful when strength, neatness, and resistance to fraying are essential.

Here are the common uses of lapped seams:

Garment Construction

Lapped seams are pivotal in garment construction, particularly in traditional and ethnic clothing.

This technique is favored for strengthening seams, ensuring that the resulting garments can endure regular wear and tear rigors.

Additionally, lapped seams have a practical application in the manufacturing of denim jeans, reinforcing inseams and outer leg seams to enhance the overall durability of these popular garments.

Home Textiles

In-home textiles and lapped seams are a reliable choice for creating curtains. These seams maintain a clean and polished appearance for curtains by preventing fraying and unraveling.

Moreover, bedding items such as sheets and pillowcases frequently incorporate lapped seams to bolster their durability, ensuring they withstand the stresses of daily use and laundering.

Industrial and Workwear

Industries requiring robust and long-lasting clothing often use lapped seams to construct work uniforms.

This strategic use ensures that the garments can withstand the demanding environments and activities of various professions.

Moreover, protective gear, including coveralls and aprons, benefits from the added strength provided by lapped seams, enhancing the overall resilience of the garments.

Outdoor Gear

Manufacturing outdoor gear, such as tents and camping equipment, often relies on lapped seams.

This technique creates a formidable barrier against the elements, contributing to seams’ water resistance and prolonging the gear’s life.

In backpacks, lapped seams are strategically employed in areas like straps and stress points, reinforcing these critical components and ensuring durability under heavy loads and challenging conditions.

Accessories

In the realm of accessories, lapped seams are integral to constructing bags and purses. This application ensures that the seams remain secure, even when subjected to the demands of everyday use.

Furthermore, belts and straps, whether crafted from leather or fabric, frequently incorporate lapped seams.

This provides added strength to these accessories and prevents fraying at the edges, contributing to their longevity and aesthetic appeal.

Automotive Upholstery

Within automotive upholstery, lapped seams find widespread application. This sewing technique contributes significantly to the durability and longevity of seat covers and other interior components.

By withstanding the wear and tear associated with daily use, lapped seams play a crucial role in maintaining the overall quality and appearance of car interiors.

Lapped Seam Types in Sewing

Lapped seams in sewing refer to techniques where one fabric edge is overlapped by another and then stitched into place.

These seams are commonly used for their strength, durability, and ability to create a neat and finished appearance.

There are several types of lapped seams, each with its unique characteristics and applications:

Single-Lapped Seam

One fabric edge is neatly folded over the other in a single-lapped seam, creating a straightforward yet effective seam. This technique is commonly employed in lightweight fabrics where a subtle finish is desired.

It’s frequently used for straight seams in skirts, blouses, and dresses, providing a clean and polished look without adding bulk.

Double-Lapped Seam

The double-lapped seam offers increased strength compared to its single-lapped counterpart. In this technique, both fabric edges are folded over each other, resulting in a symmetrical appearance.

This type of lapped seam is beneficial in heavier fabrics or areas of a garment that experience more stress, such as the crotch seam in trousers. It provides a robust and durable finish, ensuring the garment’s longevity.

Mock-Fell Seam

The mock-fell seam is a practical compromise between simplicity and durability. Mimicking the appearance of a traditional fell seam, one fabric edge is folded over the other, and both layers are secured with a topstitched line.

This lapped seam is commonly found in denim and other heavyweight fabrics, offering strength without the complexity of an accurate fell seam.

Flat-Felled Seam

A flat-felled seam is renowned for its strength and durability. In this method, one fabric edge is folded over the other, and both layers are stitched down with a second line of stitching.

This seam is a staple in jeans, shirts, and other garments where ruggedness is crucial. The flat-felled seam reinforces the fabric and provides a clean, finished look on both sides.

French Fell Seam

The French fell seam takes the principles of the flat-felled seam and adds a touch of elegance. One fabric edge is folded over the other, and the raw edges are enclosed.

This results in a polished seam that is suitable for lightweight fabrics. The French fell seam is often chosen for its neat finish on both sides, making it a favored choice in garments where interior aesthetics matter.

Bound Seam

A bound seam involves encasing the raw edges of a lapped seam with bias tape or another fabric strip. This adds a decorative element and serves a practical purpose by preventing fraying.

Bound seams are commonly used in lingerie and delicate garments where a clean, finished edge is essential. The added layer of fabric enhances the seam’s durability and visual appeal.

Welt Seam

Welt seams are a distinctive choice often seen in tailored garments. In this lapped seam variation, one fabric edge is neatly folded over and stitched to the other, creating a raised, decorative ridge.

This technique adds a sophisticated touch to a garment, especially coat construction. The welt seam showcases meticulous craftsmanship and contributes to the overall polished appearance of the finished piece.

Lapped Seam vs. Flat Felled

Lapped and flat-felled seams are both widely utilized techniques in sewing, each offering unique characteristics and benefits.

While they share similarities in strength and durability, their construction methods and final appearances differ.

Understanding the distinctions between lapped and flat-felled seams can empower sewers to choose the most suitable technique for their projects.

The following table provides a concise comparison of these two common seam types:

| Aspect | Lapped Seam | Flat-Felled Seam |

| Construction Method | One fabric edge is folded over the other, creating an overlap. | One fabric edge is folded over the other, and both layers are stitched down with a second line of stitching. |

| Strength and Durability | Appearance on the Right Side | Renowned for its exceptional strength, it is often used in heart-renowned and rugged garments. |

| Appearance on the Wrong Side | Clean, with a single visible stitching line along the overlapped edge. | Clean and finished, with two visible stitching lines creating a folded ridge. |

| Typically, it shows raw edges on the inside. | It is commonly used in jeans, shirts, and other garments where durability and a polished look are essential. | Neat and enclosed, with no raw edges visible. |

| Common Applications | Found in a range of garments, especially those with lightweight to medium-weight fabrics. | It requires precision and attention to detail, making it more advanced than a simple lapped seam. |

| Ease of Construction | It often includes topstitching on both sides of the seam, adding reinforcement and a decorative touch. | It is relatively straightforward and suitable for beginners. |

| Topstitching | Optional, depending on the desired aesthetic. | It is particularly well-suited for heavy-duty projects and garments where extra durability is crucial. |

| Versatility | Versatile and suitable for a variety of projects. | Particularly well-suited for heavy-duty projects and garments where extra durability is crucial. |

FAQs

What Is a Lapped Seam?

A lapped seam is a sewing technique where one fabric edge is overlapped onto another and then stitched into place.

This method is widely used for its ability to provide strength, durability, and a neat finish to various garments and textile projects.

Why Do You Need a Lapped Seam Diagram?

A lapped seam diagram is a visual guide illustrating the step-by-step process of creating a lapped seam.

It aids sewers in understanding the proper alignment, folding, and stitching techniques required for this sewing method.

To Recap

The lapped seam stands as a fundamental and adaptable technique in the art of sewing. Its simplicity and efficacy make it accessible to beginners, while its strength and versatility appeal to seasoned crafters.

Whether used in traditional clothing, denim jeans, or delicate textiles, the lapped seam ensures durable and polished connections between fabric pieces.

As sewers continue to explore and master this essential skill, they enhance their ability to create garments that showcase craftsmanship and withstand the test of time.

The lapped seam remains a cornerstone in sewing, exemplifying the fusion of functionality and aesthetic precision.

Leave a Reply