A Teflon sewing needle represents a precision tool tailored to the demands of modern sewing machines.

Crafted with a metal core and a specialized Teflon coating, these needles offer a unique combination of strength and non-stick properties.

The Teflon coating, derived from polytetrafluoroethylene (PTFE), provides a smooth glide, reducing friction during the sewing process.

This makes Teflon sewing needles particularly advantageous when working with delicate fabrics like silk or in quilting projects.

Their ability to effortlessly navigate multiple layers of fabric and tackle challenging materials like leather and vinyl positions them as essential tools for sewers seeking precision, efficiency, and versatility in various sewing applications.

What Is a Teflon Sewing Needle?

A Teflon sewing needle is a specialized needle used in sewing machines, designed with a coating of polytetrafluoroethylene (PTFE), commonly known as Teflon.

Teflon is a nonstick material that provides several advantages in the sewing process. The primary purpose of the Teflon coating is to reduce friction between the needle and the sewn fabric, ensuring smooth and effortless stitching.

This is particularly beneficial when working with materials that stick or create drag, such as leather, vinyl, or other synthetic fabrics.

The Teflon coating on the needle helps prevent the buildup of residue and adhesive substances from the sewn materials, reducing the risk of needle breakage and prolonging the needle’s lifespan.

Teflon sewing needles are famous among sewists and quilters for their ability to facilitate easy, seamless stitching through challenging fabrics, ultimately contributing to a more efficient and enjoyable sewing experience.

What Is a Teflon Sewing Needle Made Of?

A Teflon sewing needle is a specialized type designed for use in sewing machines, mainly when non-stick properties are crucial. These needles typically have two main components: a metal core and a Teflon coating.

Metal Core

The metal core of a Teflon sewing needle plays a critical role in providing the needle with structural integrity and resilience.

Stainless and nickel-plated steel are commonly chosen materials for this core due to their robust nature.

Stainless steel, known for its corrosion resistance and strength, ensures the needle maintains its shape even when subjected to the repetitive forces and pressures of sewing.

Nickel-plated steel offers additional durability and a smooth surface, contributing to the needle’s longevity.

Teflon Coating

The distinguishing feature of Teflon sewing needles lies in applying a Teflon coating on the metal core.

Teflon, scientifically known as polytetrafluoroethylene (PTFE), is a synthetic polymer renowned for its exceptional non-stick properties. The Teflon coating on the needle serves several purposes, enhancing the overall sewing experience.

One significant advantage of Teflon is its innate slipperiness, significantly reducing friction between the needle and the fabric.

This property allows the needle to glide smoothly through various materials, preventing snagging or damaging delicate fabrics.

What Is a Teflon Sewing Needle Used For? Key Uses

A Teflon sewing needle is a specialized needle designed for use in sewing machines, and it is specifically crafted to provide certain advantages in various sewing applications.

The primary purpose of a Teflon sewing needle is to facilitate smooth and efficient stitching by leveraging the unique properties of Teflon, a synthetic polymer known for its non-stick characteristics.

Here are some critical uses and benefits of Teflon sewing needles:

Sewing Delicate Fabrics

Teflon sewing needles shine with delicate fabrics like silk, satin, or chiffon. The non-stick properties of the Teflon coating come to the forefront, offering a seamless glide through these fragile materials.

Beyond just preventing snags and pulls, the Teflon-coated needle ensures a level of precision crucial in projects requiring meticulous care.

Whether crafting elegant garments or delicate accessories, the Teflon sewing needle becomes an indispensable tool for achieving flawless results with finesse.

Quilting

Quilting demands precision as it often involves maneuvering through multiple layers of fabric and batting.

Teflon sewing needles can smoothly navigate through these layers without causing bunching or distortion.

The non-stick surface of the needle facilitates a fluid stitching process, ensuring that the layers move seamlessly.

Quilters benefit from the Teflon-coated needle’s ability to maintain accuracy and create even, well-defined stitches, contributing to the overall quality and durability of the quilt.

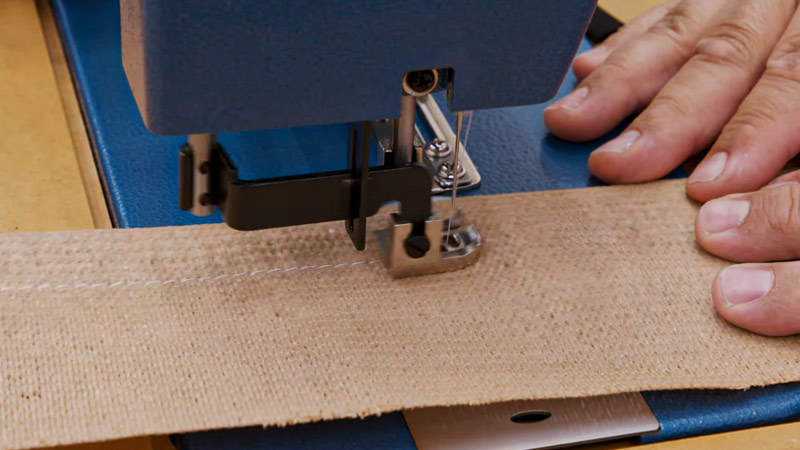

Leather and Vinyl Work

Sewing through dense materials like leather or vinyl poses challenges, but Teflon sewing needles rise to the occasion.

These needles effortlessly penetrate through the more rigid surfaces by reducing friction without compromising precision.

The non-stick coating prevents the needle from sticking and ensures a clean, mark-free finish.

Crafters and artisans working on leather goods or vinyl projects find Teflon sewing needles invaluable tools, allowing them to easily achieve professional results.

Adhesive or Coated Fabrics

Fabrics with adhesive backing or specialized coatings can be problematic for traditional needles, leading to gumming up and residue.

Teflon sewing needles overcome this issue with their non-stick surface, preventing the accumulation of adhesives or coatings.

This feature ensures a cleaner and more efficient sewing process, making these needles particularly suitable for projects involving laminated fabrics, adhesive-backed materials, or any textiles with specialized coatings.

Machine Embroidery

In the realm of machine embroidery, precision and smooth stitching are paramount. Teflon sewing needles prove advantageous by seamlessly gliding through the intricate embroidery process without catching on threads or fabric.

The non-stick coating enhances the needle’s ability to navigate through densely stitched areas, resulting in cleaner and more intricate designs.

Teflon sewing needles have become an essential choice for embroiderers seeking professional-grade detailing and consistency.

Reducing Thread Breakage

The Teflon coating on these needles offers more than just non-stick properties; it significantly reduces friction during the sewing process.

This reduction in friction plays a crucial role in minimizing the likelihood of thread breakage. This feature is particularly beneficial when working with specialty threads or those prone to tangling.

The Teflon sewing needle becomes a reliable companion for sewers aiming for uninterrupted, smooth stitching, even in challenging thread conditions.

Advantages of Using Teflon Coated Sewing Needles

Using Teflon-coated sewing needles offers a range of advantages, making them a preferred choice for various sewing applications.

Here are the key benefits of using Teflon-coated sewing needles:

Reduced Friction

Teflon, or polytetrafluoroethylene (PTFE), is renowned for its exceptional non-stick properties. When applied as a coating on sewing needles, it significantly reduces friction between the needle and the fabric.

This reduction in friction allows the needle to glide smoothly through the material, preventing snags, pulls, and potential damage to delicate fabrics.

Suitability for Delicate Fabrics

Teflon-coated sewing needles are well-suited for working with delicate fabrics such as silk, satin, or chiffon.

The non-stick surface ensures that the needle moves seamlessly through these refined materials, providing precision essential for projects that require careful handling of delicate fabrics.

Efficient Quilting

Quilting often involves stitching through multiple layers of fabric and batting. Teflon-coated needles excel in quilting applications by smoothly navigating through these layers without causing bunching or distortion.

This efficiency ensures that quilters can achieve even and precise stitching, contributing to the quality of the quilt.

Ease of Sewing Leather and Vinyl

Sewing through dense materials like leather or vinyl can be challenging, but Teflon-coated needles easily handle these tasks.

The reduced friction allows the needle to move effortlessly through more challenging surfaces, preventing sticking and leaving a clean finish.

This makes Teflon-coated needles an excellent choice for projects involving leather goods or vinyl applications.

Prevention of Residue Buildup

The non-stick nature of Teflon prevents the accumulation of adhesive residues, coatings, or lint on the needle. This is especially advantageous when working with fabrics that have adhesive backing or specialized coatings.

The absence of residue ensures a cleaner sewing process, reducing the need for frequent needle cleaning and maintenance.

Smooth Machine Embroidery

In machine embroidery, precision, and smooth stitching are crucial. Teflon-coated needles facilitate a seamless glide through embroidery without catching on threads or fabric.

The non-stick coating enhances the needle’s ability to navigate densely stitched areas, resulting in cleaner and more intricate designs.

Longer Needle Lifespan

The Teflon coating not only benefits the sewing process but also contributes to the longevity of the needle.

The reduced friction and prevention of residue buildup mean that Teflon-coated needles are less prone to wear and tear. This results in a longer lifespan for the needle, providing cost-effectiveness for sewers.

Reduced Thread Breakage

The decreased friction the Teflon coating provides minimizes the likelihood of thread breakage during the sewing process.

This is particularly advantageous when working with specialty threads or threads prone to tangling, ensuring a smoother and more uninterrupted sewing experience.

Drawbacks of Teflon Sewing Needles

While Teflon-coated sewing needles offer several advantages, it’s essential to consider potential drawbacks associated with their use.

Here are some considerations:

Cost

Teflon-coated sewing needles tend to be more expensive than their non-coated counterparts. The manufacturing process of applying Teflon coating adds to the production cost, which may impact the overall cost of the needles. For budget-conscious sewers, this can be a significant factor to consider.

Limited Needle Options

Teflon-coated needles may not be available in as wide a variety of sizes and types as traditional needles.

Some specialty needles or specific needle configurations may not be offered with a Teflon coating. This limitation could be a constraint for sewers with particular project requirements.

Durability Concerns

While Teflon coating contributes to the longevity of the needle, it is not entirely immune to wear and tear.

Over time, the Teflon coating may wear off, especially with heavy or prolonged use. This could diminish the non-stick properties, reducing the effectiveness of the needle.

Application Limitations

Teflon-coated needles are designed to excel in specific applications, such as sewing delicate fabrics or working with materials like leather and vinyl.

However, they may not be the optimal choice for all sewing projects. For example, a traditional needle without Teflon coating might be more suitable in heavy-duty applications where maximum durability is required.

Special Handling Requirements

Teflon-coated needles may require specific handling to maintain their non-stick properties. Aggressive or improper cleaning methods, such as abrasive materials, could damage the Teflon coating.

Sewers need to be mindful of proper care to ensure the longevity and effectiveness of Teflon-coated needles.

Dependency on Fabric Type

While Teflon-coated needles benefit delicate fabrics, quilting, and certain materials, they may not be necessary for all sewing projects.

For standard sewing tasks on regular fabrics, the advantages of Teflon coating might not be as pronounced, making using these needles somewhat situation-dependent.

Environmental Considerations

Teflon is a synthetic polymer, and the production and disposal of Teflon-coated products may raise environmental concerns.

While Teflon itself is generally inert, environmentally conscious sewers should consider the environmental impact of the manufacturing process and potential disposal issues.

FAQs

Why are Teflon sewing needles suitable for delicate fabrics?

Teflon sewing needles are ideal for delicate fabrics due to their non-stick coating, preventing snags and ensuring smooth stitching on materials like silk or chiffon.

Can Teflon sewing needles be used for quilting?

Yes, Teflon sewing needles are effective for quilting, smoothly navigating through multiple fabric layers without causing bunching or distortion.

What advantages do Teflon-coated needles offer in leather and vinyl work?

Teflon-coated needles excel in sewing through rigid materials like leather and vinyl, reducing friction and preventing marks or residue.

To Recap

A Teflon sewing needle is a specialized tool designed to enhance the sewing experience, particularly in delicate or challenging applications.

With a metal core for strength and a Teflon coating for non-stick properties, these needles smoothly navigate through fabrics like silk, quilting layers, or rigid materials like leather and vinyl.

The reduced friction minimizes snags, promotes precision, and produces a cleaner sewing process.

While Teflon sewing needles may have associated costs and application limitations, their advantages in specific projects make them invaluable tools for sewers seeking efficiency, durability, and high-quality stitching in various sewing applications.

Leave a Reply