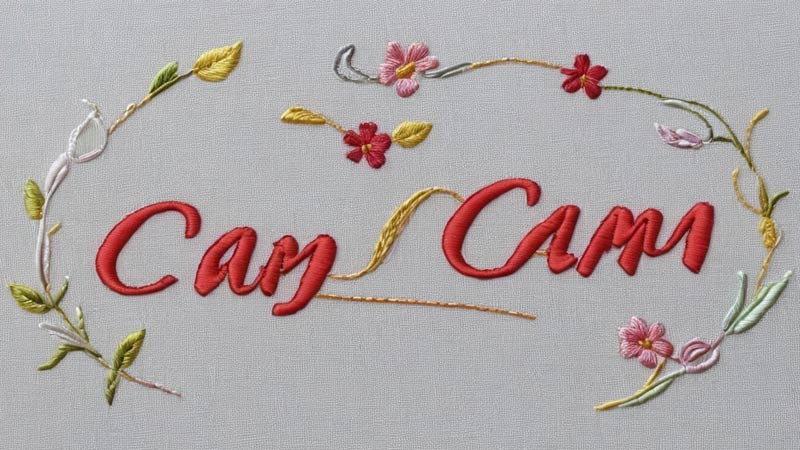

Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) embroidery represents a transformative synergy of technology and textile artistry.

This innovative approach harnesses the power of specialized software and automated machinery to revolutionize the traditional embroidery craft.

CAD/CAM embroidery allows designers to digitally create, manipulate, and optimize intricate designs, transcending the limitations of manual methods.

The process involves translating these digital designs into machine-readable instructions, ensuring precise replication on fabric.

This technology enhances creative possibilities with its design flexibility and streamlines production, offering benefits such as time efficiency, mass production capabilities, and the ability to meet the growing demand for personalized and customized textile products.

What Is Cad Cam Embroidery?

CAD CAM embroidery is a computerized process that uses computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to create embroidery designs.

CAD software simplifies the process of designing textile elements like printed surface patterns and garments, while CAM technology manages all aspects of the manufacturing process.

CAM takes the design and prepares the textile pattern in embroidery, including embroidery-specific information like stitches and thread color.

The stitchable design is then exported to machine-specific formats for embroidery. CAD CAM embroidery is widely used in textile and garment manufacturing to improve large-scale production productivity, efficiency, and accuracy.

This technology not only enhances the efficiency of the embroidery process but also enables the creation of complex and highly detailed designs that would be challenging to achieve manually.

CAD-CAM embroidery has become a cornerstone in the textile industry, offering a perfect blend of creativity and precision in the art of embroidery.

What Is Cad Cam Embroidery Used For?

Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) embroidery refers to the use of technology in designing and producing intricate embroidered patterns on fabrics.

This advanced system combines the power of computer software with automated machinery to streamline the embroidery process, offering numerous benefits to industries and individuals involved in textile decoration.

Here’s an overview of what CAD/CAM embroidery is used for:

Design Creation and Editing

CAD/CAM embroidery software empowers designers to unleash their creativity by offering a versatile platform for creating and manipulating digital embroidery designs.

Designers can experiment with an extensive array of shapes, colors, and patterns, pushing the boundaries of traditional embroidery.

The software’s intuitive tools allow for precise control over every stitch, realizing intricate and complex patterns that would be challenging, if not impossible, to achieve through manual methods.

This digital design process enhances precision and opens up new possibilities for artistic expression in embroidery.

Digitizing Artwork

The digitization process in CAD/CAM embroidery is a crucial bridge between artistic vision and machine execution.

This intricate process involves converting hand-drawn or computer-generated artwork into a format that embroidery machines can comprehend.

Highly skilled digitizers meticulously translate every nuance of the design into a series of instructions, guiding the machine to replicate the original artwork accurately.

This step is pivotal in ensuring that the final embroidered product faithfully reflects the designer’s intent, maintaining the integrity of the intricate details and textures inherent in the original artwork.

Customization and Personalization

One of the standout features of CAD/CAM embroidery is its ability to cater to individual preferences through customization and personalization.

Businesses can leverage this technology to create unique, one-of-a-kind items by adding personalized touches such as monograms, logos, or individual names.

This level of customization is precious in industries like apparel, where consumers increasingly seek personalized products.

From sports jerseys to corporate uniforms, CAD/CAM embroidery enables businesses to offer a personalized touch that resonates with their customers.

Mass Production

The automation capabilities of CAD/CAM embroidery machines bring unparalleled efficiency to mass production. These machines excel at reproducing intricate designs consistently and quickly on a large scale.

By automating the embroidery process, businesses can meet the demands of high-volume production without compromising on the quality or uniformity of the finished products.

This scalability is especially advantageous for industries requiring large quantities of embroidered items, such as the production of uniforms, patches, or promotional merchandise for events and campaigns.

Quality and Precision

CAD/CAM embroidery sets a high standard for precision and quality in the final output. The digital nature of the design process minimizes the risk of human error and ensures consistency in every stitch.

This meticulous attention to detail results in more accurate and finely detailed embroidered products, meeting the high standards demanded by industries and consumers alike.

The combination of automation and precision contributes to producing visually stunning and top-quality embroidered items.

Textile Industry Applications

In the textile industry, CAD/CAM embroidery is a transformative tool for enhancing the aesthetic appeal of garments, home textiles, and accessories.

Beyond basic embellishments, designers can use the technology to create intricate and elaborate patterns that elevate the visual appeal of textiles.

Whether adding decorative elements to fashion or creating unique designs for home decor items, CAD/CAM embroidery has become an indispensable part of the textile industry’s quest for innovation and marketability.

Reduced Production Time

CAD/CAM embroidery automation enhances creativity and significantly reduces the overall production time. Traditional embroidery methods, especially for intricate designs, can be time-consuming.

The entire process is expedited with CAD/CAM technology, from initial design creation to the finished embroidered product.

This allows businesses to meet tight deadlines and improves overall efficiency, making CAD/CAM embroidery a time-saving solution in the fast-paced world of textile production.

Benefits of Using Cad Cam Embroidery

Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) embroidery offers many benefits across various textile decoration industries.

Here are the key advantages of using CAD/CAM embroidery:

Design Flexibility and Creativity

CAD/CAM embroidery provides designers with high flexibility and creativity. The specialized software allows for the creation of intricate and complex designs with precision.

Designers can experiment with different shapes, colors, and patterns, pushing the boundaries of traditional embroidery and bringing new levels of artistic expression to the forefront.

Digital Precision and Consistency

The digital nature of CAD/CAM embroidery ensures high precision and consistency in the final output.

Every stitch is guided by digital instructions, minimizing the risk of human error and ensuring that each embroidered product faithfully replicates the original design. This level of accuracy is particularly crucial for intricate and detailed designs.

Time Efficiency and Expedited Production

Automation is a key feature of CAD/CAM embroidery, significantly reducing the time required for production.

Compared to traditional embroidery methods, which can be time-consuming, CAD/CAM technology streamlines the entire process from design creation to the finished product.

This allows for faster turnaround times and enables businesses to meet tight deadlines and respond quickly to market demands.

Customization and Personalization

CAD/CAM embroidery is highly versatile for customization and personalization.

Businesses can easily incorporate individual names, logos, or specific details into designs, catering to the growing demand for personalized products.

This feature is precious in industries such as apparel, promotional products, and corporate branding, where unique and tailored items are in high demand.

Mass Production Capabilities

The automation capabilities of CAD/CAM embroidery machines make them well-suited for mass production.

These machines can reproduce intricate designs consistently and quickly on a large scale, ensuring efficiency and uniformity in the production process.

This scalability benefits industries that require high-volume embroidery, such as producing uniforms, patches, or promotional merchandise.

Enhanced Textile Industry Applications

In the textile industry, CAD/CAM embroidery enhances textile products. The technology allows for diverse applications, from embellishing garments to creating intricate patterns on home textiles and accessories.

Designers can explore innovative ways to elevate the visual appeal of textiles, leading to unique and marketable products.

Reduced Labor Costs

The automation and efficiency of CAD/CAM embroidery can reduce labor costs. With fewer manual processes, businesses can optimize their production workflows and allocate resources more effectively.

This cost-effectiveness is especially valuable for industries aiming to enhance profitability without compromising the quality of embroidered products.

Conservation of Resources

CAD/CAM embroidery minimizes material wastage by optimizing the use of thread and fabric. The precision of the digital design process ensures that resources are utilized efficiently, contributing to a more sustainable and environmentally friendly production approach.

FAQs

What Is CNC Embroidery?

CNC embroidery is Computer Numerical Control embroidery, where automated machines use digital instructions for precise and intricate embroidery on fabrics.

What Do You Mean by Cad Cam?

CAD/CAM is Computer-Aided Design and Manufacturing, a technology combining software and machinery for digital design creation and automated production commonly used in embroidery.

What Is CAD in Sewing?

CAD in sewing stands for Computer-Aided Design, employing software for digital pattern creation before translating designs into physical sewing projects.

What Is Cad Cam Operation?

CAD/CAM operation seamlessly uses computer-aided design and manufacturing, where digital designs are created with CAD software and executed precisely in manufacturing processes like embroidery using CAM technology.

To Recap

CAD/CAM embroidery emerges as a revolutionary force in textile decoration, seamlessly marrying technological innovation with artistic expression.

This dynamic fusion of Computer-Aided Design and Computer-Aided Manufacturing transcends traditional embroidery constraints, offering unparalleled design flexibility, precision, and efficiency.

CAD/CAM embroidery empowers designers to push creative boundaries and facilitates mass production with consistent quality.

Its impact extends beyond aesthetics, influencing industries with reduced production times, customization capabilities, and resource optimization.

As we navigate an era where technology reshapes craftsmanship, CAD/CAM embroidery stands as a testament to the transformative power of digitization in elevating the art and industry of embroidery.

Leave a Reply