The concept of dual feed on a sewing machine is a game-changer in the world of sewing. It’s an innovative feature that revolutionizes the way fabrics are handled during the sewing process.

Whether integrated into the machine or achieved through attachment accessories like walking feet, dual feed offers precise fabric control, ensuring that layers of fabric move in perfect synchronization.

This not only eliminates common sewing challenges like fabric misalignment and puckering but also enhances stitch quality.

Dual feed is a versatile tool, making it ideal for a wide range of sewing tasks, from quilting to working with delicate materials.

In this exploration, we delve into the essence of dual feed and its profound impact on sewing outcomes.

What Is Dual Feed on a Sewing Machine?

Sewing enthusiasts, both beginners and seasoned professionals, are likely to come across the term “dual feed” when exploring the capabilities of their sewing machines.

Dual feed, often referred to as a walking foot or IDT (Integrated Dual Feed), is a mechanism integrated into many modern sewing machines.

It’s designed to help prevent fabric layers from shifting, stretching, or puckering while you sew.

The dual feed system consists of two sets of feed dogs – one below the fabric and another on top of it.

These feed dogs work in tandem to ensure that the upper and lower layers of fabric are fed through the machine at the same rate.

How Does Dual Feed Work on a Sewing Machine?

Dual feed, also known as a walking foot or IDT (Integrated Dual Feed) system, is a feature found on some sewing machines that helps to feed multiple layers of fabric evenly through the machine.

This feature is especially useful when working with challenging fabrics or multiple layers, such as quilting, sewing leather, or handling slippery materials like satin or silk.

Here’s how the dual feed works on a sewing machine:

Mechanism

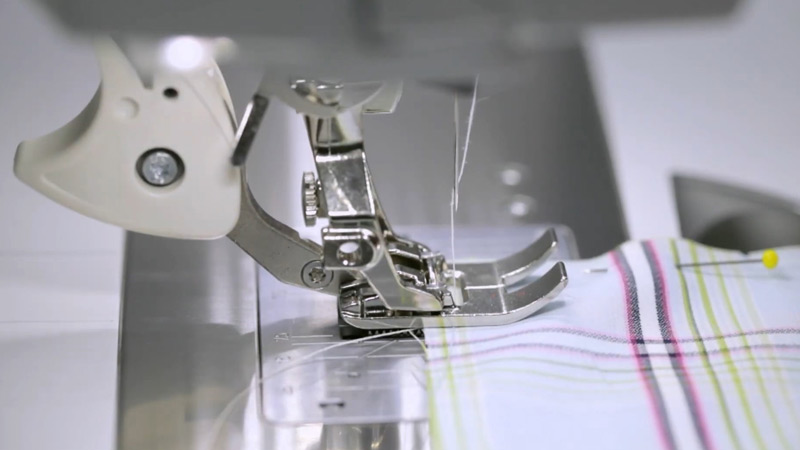

The dual feed mechanism consists of an additional set of feed dogs (the toothed mechanism that moves the fabric under the presser foot) located on top of the fabric. These feed dogs work in tandem with the regular feed dogs below the fabric.

Engagement

To use the dual feed feature, you need to engage it on your sewing machine. The process can vary depending on the machine’s make and model.

Some machines have a lever or button to activate the dual feed, while others may have it built-in as a permanent feature.

Equal Fabric Movement

When the dual feed is engaged, the upper set of feed dogs will move in synchronization with the lower set.

This ensures that both layers of fabric (top and bottom) are pulled through the machine at the same rate. As a result, the layers stay aligned and don’t shift or bunch up, which can lead to uneven stitching.

How to Use Dual Feed of a Sewing Machine?

Using a dual-feed sewing machine can greatly assist in handling difficult fabrics or sewing multiple layers of fabric evenly.

Here are the general steps for using the dual feed feature:

Machine Preparation

Before you begin sewing with the dual feed or walking foot, ensure your sewing machine is set up and prepared for your specific project.

This includes selecting the appropriate thread, needle, and stitch type based on your fabric and sewing requirements. Additionally, make sure your machine is threaded correctly following the manufacturer’s instructions.

Attachment

To utilize the dual feed feature, you’ll need to attach the dual feed foot, also known as the walking foot, to your sewing machine.

This attachment may involve securing it to the presser foot holder, aligning it with the needle, and fastening it in place according to your sewing machine’s manual. Ensure that it’s firmly attached to the machine.

Activation

Many sewing machines with a dual feed feature have a lever, button, or switch dedicated to activating it.

Refer to your machine’s manual to identify the control for the dual feed system and engage it before you start sewing. The walking foot should now be in sync with the regular feed dogs of the machine.

Fabric Positioning

Place the layers of fabric you intend to sew under the walking foot. It’s crucial to ensure that the fabric layers are aligned and positioned as required for your specific project. The walking foot will help maintain alignment as you sew.

Presser Foot Placement

Lower the presser foot to hold the fabric layers in place. As you do this, the walking foot should come into contact with the fabric, assisting in even feeding.

Ensure the presser foot is securely lowered to prevent any fabric from shifting during sewing.

Sewing

Begin sewing your project as you typically would. Use an appropriate and consistent stitch length for your fabric and sewing task.

The dual feed system will work in tandem with the machine’s regular feed dogs to help move both the upper and lower fabric layers simultaneously.

Fabric Guidance

While sewing, gently guides the fabric through the machine, helping to prevent any potential shifting or puckering. The dual feed system should assist in keeping the layers aligned and feeding evenly.

Monitoring

Keep a close eye on the fabric as you sew. Continuously monitor to ensure that both layers are being fed evenly. This is crucial for maintaining the quality of your stitches and preventing fabric misalignment.

Disengagement

If you’ve completed the section of your project that requires the dual feed, consult your machine’s manual for instructions on disengaging this feature.

Typically, there will be a designated lever, button, or switch to release the walking foot’s engagement.

Finishing

Complete your sewing by following your project’s instructions. Make any necessary final adjustments to machine settings such as tension or stitch length to ensure the desired result.

Final Inspection

After finishing your sewing, trim any loose threads and carefully inspect your stitches to ensure they meet your quality standards.

Ensure that the fabric layers remain properly aligned and that there are no issues such as puckering or shifting.

Why Is Dual Feed Important for a Sewing Machine?

The dual feed feature, often referred to as a walking foot or IDT (Integrated Dual Feed) system, plays a crucial role in enhancing the capabilities of a sewing machine.

This mechanism is of paramount importance in sewing for several reasons:

Even Fabric Feeding

One of the primary benefits of the dual feed system is that it ensures both the upper and lower layers of fabric are fed through the machine evenly.

This is especially crucial when working with multiple layers of fabric, thick fabrics, or slippery materials. Uneven feeding can lead to misalignment, puckering, or even fabric damage.

Prevents Fabric Shifting

Dual feed prevents fabrics from shifting or bunching during sewing. This is particularly valuable when quilting, as it helps maintain the alignment of quilt layers, reducing the likelihood of wrinkles or tucks in the finished quilt.

Improved Stitch Quality

The even feeding provided by the dual feed system contributes to better stitch quality. Stitches are more consistent in length and appearance, resulting in a more professional-looking finished product.

Versatility

Dual feed makes it easier to work with a wide range of fabrics, from delicate silks to heavy denim and leather. It reduces the need for manual fabric handling techniques like pinning, taping, or basting, which can be time-consuming and less accurate.

Reduced Puckering

When sewing lightweight or stretchy fabrics, puckering is a common issue. The dual feed system helps mitigate puckering by keeping the fabric layers taut and feeding them evenly.

Enhanced Control

Sewers have better control over their sewing projects when using the dual feed system. This is especially important for precision sewing tasks, such as quilting or attaching binding to a quilt edge.

Increased Productivity

With the dual feed system, sewers can work more efficiently, as they spend less time correcting fabric alignment issues or dealing with problems like fabric jamming.

Versatility for Specialized Tasks

Some sewing machine attachments, such as walking feet or specialized feet, are designed to work in conjunction with the dual feed system.

This enables sewers to tackle specific tasks like topstitching, attaching bias tape, or sewing thick seams with ease.

Less Strain on the Sewer

When working with challenging fabrics or multiple layers, sewers often need to exert more force to guide the fabric through the machine.

The dual feed system reduces this strain, making sewing more comfortable and less physically demanding.

Consistency

Whether you’re a beginner or an experienced sewer, the dual feed system helps maintain consistent results, reducing frustration and ensuring that your sewing projects turn out as intended.

Benefits of Using Sewing Machines With Built-in Dual Feed

Using sewing machines with built-in dual feed, also known as Integrated Dual Feed (IDT) systems, offers a range of significant benefits for sewers and quilters.

Here are some key advantages of dual-purpose sewing machines:

Precise Fabric Control

One of the primary benefits of using a sewing machine with a built-in dual feed is precise fabric control. The dual feed mechanism ensures that the top and bottom layers of fabric move in perfect synchronization.

This prevents the fabric from shifting or bunching during sewing, resulting in accurately aligned seams and patterns.

Even Fabric Feeding

Dual feed systems ensure that both layers of fabric are fed evenly through the machine. This prevents issues like fabric distortion, puckering, or uneven stitching, which can be common when working with challenging fabrics or multiple layers.

Versatility

Sewing machines with built-in dual feed are versatile and suitable for a wide range of sewing tasks. They excel in projects that involve multiple layers of fabric, making them ideal for quilting, sewing heavy fabrics, and handling delicate materials with ease.

Improved Stitch Quality

The even fabric feeding provided by dual feed systems results in improved stitch quality. You can achieve neat, consistent, and professional-looking stitches on a variety of fabrics.

Reduced Effort

With dual feed in action, there is less need for manual fabric manipulation or the use of additional accessories like walking feet. Sewing becomes less physically demanding, allowing you to focus on your creativity without exerting excessive effort.

Time Savings

Dual feed systems save time by minimizing the need to stop and adjust fabric alignment. Sewing projects progress more efficiently, and you can complete tasks more quickly.

Enhanced Quilting

Quilters benefit significantly from the even fabric feeding provided by dual feed systems. Quilting layers stay properly aligned, ensuring that stitches follow the intended design, and quilts come out flat and well-finished.

User-Friendly

Sewing machines with built-in dual feed are user-friendly and suitable for sewers of all skill levels. They are particularly helpful for beginners who may struggle with fabric handling issues on standard machines.

Consistency

The consistent fabric feeding provided by dual feed systems ensures that every stitch is uniform. This is essential for projects where precision is critical, such as garment construction, piecing quilts, or creating decorative topstitching.

Reduced Waste

By preventing fabric misalignment and errors, dual feed systems can help reduce fabric waste. You’ll have fewer instances of having to re-cut or rework fabric due to sewing mishaps.

FAQS

What is the difference between a walking foot and a built-in dual feed system?

A walking foot is an attachment you can add to some sewing machines to achieve dual feed.

Built-in dual feed systems are integrated features in certain sewing machines that provide the same benefits without requiring additional attachments.

Can I use a walking foot on a sewing machine with a built-in dual feed system?

Generally, you don’t need to use both simultaneously. It’s typically one or the other.

Are dual feed systems suitable for all types of fabric?

While dual feed can improve fabric handling for a wide range of materials, it may not be necessary for lightweight and easily managed fabrics like cotton.

Do I need special needles or threads when using the dual feed feature?

You don’t typically need special needles or threads for dual feed.

Can I engage and disengage the dual feed feature while sewing?

Yes, you can often engage and disengage the dual feed feature as needed during your sewing projects.

Where can I find fabric stores in Billings, MT?

Billings, Montana has several fabric stores to explore for your sewing and crafting needs.

To Recap

The dual feed mechanism on a sewing machine is a remarkable innovation that transforms the sewing experience.

Whether through integrated systems or attachment accessories like walking feet, dual feed ensures precise fabric control, preventing misalignment, bunching, or puckering.

It offers versatility, making it suitable for various fabrics and sewing tasks, from quilting intricate patterns to handling delicate materials with ease.

This feature substantially improves stitch quality, delivering consistent, professional results. Dual feed systems reduce manual effort and save time, allowing sewers to focus on their creative projects.

Regardless of your skill level, the dual feed is an invaluable tool that enhances sewing accuracy, efficiency, and overall sewing satisfaction.

Leave a Reply