Facing in sewing is a fundamental technique that transforms raw fabric edges into polished, professional finishes. In the world of garment construction and textile crafts, the term “facing” represents a vital component.

These fabric strips or pieces are meticulously sewn onto the inner edges of garments, offering both functional and aesthetic benefits. By enveloping and safeguarding raw edges, facings prevent fraying and enhance the overall appearance of a garment.

They can emphasize design elements, maintain a garment’s shape, and reinforce seams. Understanding the various types of facings and how to sew them is a fundamental skill for any sewing enthusiast, as it elevates the quality and aesthetics of the finished product.

What is Facing in Sewing?

Facing in sewing refers to a fabric strip or piece sewn along the raw edges of a garment to create a neat, polished finish. It conceals frayed edges, enhances the garment’s appearance, and reinforces seams.

Facings can emphasize design elements like necklines and cuffs, adding both structural support and decorative flair. They help garments maintain their shape and are available in various types, including outside facings, bias tape facings, shaped facings, and extended facings.

Facings can be made from the same fabric or a different one for contrast. This technique is a staple in sewing, ensuring a professional and refined final product.

What Are the Types of Facings Used in Sewing?

In sewing, facings are essential components that serve both functional and aesthetic purposes by neatly finishing the raw edges of a garment. There are several types of facings used in sewing, each tailored to specific areas and functions in the construction of a garment.

Here are the primary types of facings:

Outside Facing

This is the most common type of facing used in sewing. It is visible on the exterior of the garment and serves as a decorative finish for edges like necklines, armholes, and hems.

Outside facings not only conceal raw edges but also add a professional touch to the garment’s overall appearance.

Bias Tape Facing

Bias tape facings are strips of fabric cut on the bias (a 45-degree angle to the fabric’s grain) and used to finish curved or delicate edges. They come in single-fold or double-fold varieties and can be purchased pre-made or crafted from matching or contrasting fabric.

Bias tape facings are excellent for adding a decorative touch to edges.

Shaped Facing

Shaped facings are custom pattern pieces that mimic the shape of the fabric edge they are meant to finish. Usually cut from the same fabric as the garment, shaped facings provide a seamless and tailored appearance.

They are commonly used for necklines and curved edges.

Extended Facing

Extended facings are designed for garments that require closures, such as buttons or zippers. They are added to the garment’s opening area (like the front placket of a shirt) to ensure a neat, reinforced edge.

The sewing pattern guides how to fold and attach these facings to support the closures.

Interfaced Facing

In some cases, facings are interfaced. Interfacing is a separate layer of fabric or fusible material that is not visible on the garment’s exterior. It is used to provide additional stability and structure to specific areas like collars, cuffs, and plackets.

Interfaced facings help maintain the shape and form of these elements.

What is the Purpose of a Facing in Sewing?

The purpose of a facing in sewing is to provide a clean, polished, and professional finish to the raw edges of a garment or fabric project. Facings are fabric strips or pieces that are sewn to the inside of a garment, typically in areas like necklines, armholes, waistlines, and cuffs.

They serve several crucial functions:

Finishing Raw Edges

Facings neatly enclose and protect the raw edges of the fabric, preventing fraying and ensuring that the interior of the garment looks tidy and well-finished.

Professional Appearance

By concealing the raw edges and inner seams, facings enhance the overall quality and aesthetics of the garment, giving it a polished and expertly crafted look.

Emphasizing Design Elements

Facings can be used to highlight and accentuate specific design features, such as neckline contours or sleeve openings, adding a touch of style and sophistication to the garment.

Decorative Interest

In some cases, facings are intentionally designed to be visible on the garment’s exterior. Using a contrasting or coordinating fabric for the facing can introduce visual interest and contribute to the garment’s overall design and appeal.

Maintaining Shape

Facings play a crucial role in helping a garment maintain its intended shape and structure. They provide stability and support to areas like collars, cuffs, and plackets, ensuring that these elements retain their crispness and form.

Reinforcing Seams

Facings can enhance the durability of a garment by reinforcing seams, especially in high-stress areas such as closures (e.g., buttons, zippers) and openings.

This reinforcement helps distribute tension and prevents stretching or distortion.

Strength and Durability

Facings add an extra layer of fabric, strengthening the garment’s construction and making it more resilient to wear and tear over time, thereby increasing its longevity.

How to Sew a Facing?

Sewing a facing is a fundamental skill in garment construction that results in a clean and professional finish for edges and openings.

Here’s a step-by-step guide on how to sew a facing:

Cut Out the Facing

Begin by selecting your facing fabric and cutting out the facing pattern piece according to your sewing pattern’s instructions. The facing piece should match the shape and dimensions of the edge you intend to finish.

Ensure precise cutting as accuracy is crucial in achieving a neat and professional finish.

Prepare the Garment

Ensure that your garment is appropriately constructed up to the point where the facing will be attached. The garment should be fully assembled, with any raw edges that require a facing left unfinished.

It’s essential to have the garment ready and positioned for attaching the facing smoothly.

Pin the Facing

Place the facing piece right sides together with the garment fabric, aligning the edges that need finishing. Take care to match any notches, markings, or reference points on both the facing and the garment.

Pin or clip the facing to the garment along the entire edge that you intend to face, securing it firmly in place.

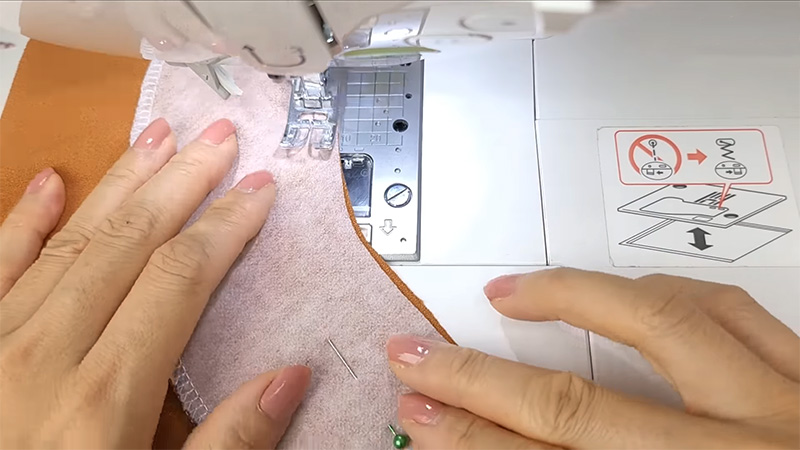

Sew the Facing

Set up your sewing machine with the appropriate thread and stitch settings, typically using a straight stitch with a 1/4-inch seam allowance or as specified in your pattern.

Start sewing at one end of the facing, ensuring a backstitch to secure the seam. Sew along the entire edge that needs facing, maintaining a consistent seam allowance.

Keep the fabric taut but not stretched as you sew.

Clip Curves and Trim Corners

For curved edges, use sharp fabric scissors to make small, evenly spaced cuts (clips) into the seam allowance. These clips allow the fabric to ease around curves smoothly and reduce bulk when the facing is turned to the inside.

For corners, trim the excess seam allowance diagonally, taking care not to cut into the stitching. This step ensures that the facing lays flat when turned.

Turn the Facing

Gently turn the facing to the inside of the garment, making sure it is fully flipped and positioned neatly along the seam line. Use your fingers or a blunt tool, like a point turner or a chopstick, to carefully push out any corners or curves.

The goal is to achieve a crisp, clean edge with no visible seams on the right side of the garment.

Press the Facing

Heat up your iron and ironing board. Press the facing flat against the garment, focusing on the edges. Ensure that the facing lies smoothly and evenly against the body of the garment.

Pressing is a critical step for achieving a polished and professional finish, and it helps set the seams and shape of the facing.

Understitch (Optional)

To help keep the facing in place and prevent it from rolling to the outside, you can choose to understitch along the seam line. Understitching involves stitching through the facing and the seam allowance, close to the seam.

This technique helps maintain the facing’s position and ensures it remains hidden on the inside of the garment.

Finish as Directed

Finally, review your sewing pattern instructions for any additional steps or finishing touches specific to your project and facing type. Follow any guidelines for securing the facing at certain points, adding topstitching, or incorporating interfacing for added stability.

What Are Some Tips for Sewing Facings?

Sewing facings can elevate your garment’s finish. Discover essential tips for achieving professional results and enhancing the quality of your sewing projects.

Here are some helpful tips for sewing facings:

Choose the Right Fabric

Select a facing fabric that complements your garment and matches its weight. Lightweight fabrics are usually the best choice for facings, as they provide a clean finish without adding unnecessary bulk.

Ensure the facing fabric is compatible with the main garment fabric to maintain a cohesive look.

Cut Accurately

Precision in cutting is crucial when working with facings. Use sharp fabric scissors and take your time to cut along the pattern lines accurately. Well-cut facings fit properly against the garment, resulting in a neater finish.

Staystitch Curved Edges

When dealing with curved edges, such as necklines or armholes, employ staystitching. This involves sewing a line of stitches just inside the seam allowance on the curved edge of your fabric.

Staystitching helps stabilize the curve, preventing it from stretching or distorting during the sewing process.

Understitch to Keep Facings in Place

To prevent facings from rolling to the garment’s exterior, use understitching. Sew a line of stitching through the facing and the seam allowance, close to the seam line.

This technique helps anchor the facing to the garment’s interior, ensuring it remains concealed and lies flat.

Press With Care

Proper pressing is essential for a polished finish. Use a pressing cloth to protect delicate fabrics and press gently to avoid stretching or distorting the fabric.

Pay extra attention to the edges and curves, ensuring they lie smoothly against the garment.

Trim Seam Allowances

After sewing and understitching, trim the seam allowances if necessary. Reducing bulk in these areas will help the facing lie flat and maintain a clean appearance.

Clip and Notch as Needed

For areas with tight curves or angles, consider making small clips or notches in the seam allowance. These strategic cuts allow the fabric to ease around curves more smoothly and can reduce bulk, enhancing the facing’s flexibility.

Test on Scrap Fabric

If you’re uncertain about the compatibility of your facing fabric or your sewing machine settings, test on a scrap piece of fabric before applying the facing to your actual garment.

This practice can help you avoid potential issues and achieve the desired result.

Follow Pattern Instructions

Always adhere to the instructions provided in your sewing pattern. Each pattern may have specific guidelines for attaching facings that are tailored to the design and construction of the garment.

Check for Proper Fit

Before finalizing the facing, check that it lies flat against the garment without any wrinkles or puckers. Make any necessary adjustments to ensure a clean and smooth finish.

What is the Difference Between Facing and Interfacing?

Facing and interfacing are two distinct components used in sewing, each serving a specific purpose in garment construction.

Here are the key differences between facing and interfacing:

Purpose

- Facing: Facings are used to finish the raw edges of a garment, particularly on openings like necklines, armholes, and waistlines. They provide a clean, polished appearance to the inside of the garment and can also be used for decorative or contrasting effects.

- Interfacing: Interfacing is employed to add structure, stability, and support to specific areas of a garment, such as collars, cuffs, plackets, and waistbands. Its primary purpose is to help these areas maintain their shape.

Visibility

- Facing: Facings are meant to be visible on the inside of the garment. They are attached to the raw edges and can be seen when you flip the garment inside out.

- Interfacing: Interfacing is not intended to be visible from the outside of the garment. It is typically sandwiched between layers of fabric, providing reinforcement without altering the garment’s exterior appearance.

Fabric Type

- Facing: Facings are usually made from the same fabric as the garment, although they can also be made from contrasting or complementary fabrics for design purposes.

- Interfacing: Interfacing can be constructed from various materials, including woven or non-woven fabrics. It can be fusible (adhered to fabric with heat) or sewn-in, depending on the desired effect and the fabric being used.

Location

- Facing: Facings are commonly found on openings and edges of the garment where a clean finish is necessary, such as the neckline, armholes, and waistline.

- Interfacing: Interfacing is typically applied to structural elements like collars, cuffs, plackets, and waistbands to provide shape and reinforcement.

Attachment Method

- Facing: Facings are sewn directly to the raw edges of the fabric using regular sewing stitches.

- Interfacing: Interfacing can be sewn into place or fused to the fabric using heat (fusible interfacing). Fusible interfacing has an adhesive side that adheres to the fabric when heat is applied with an iron.

FAQs

Can facings be made from the same fabric as the main garment?

Yes, facings are often made from the same fabric as the main garment to ensure a cohesive look. However, they can also be made from contrasting fabric for decorative purposes.

Are there alternatives to facings for finishing raw edges in sewing?

Yes, alternatives include techniques like binding, lining, or serging, but facings are a common and versatile choice for achieving clean edges.

Do all sewing patterns include instructions for facings?

Most sewing patterns that require facings will include specific instructions. However, not all projects may necessitate facings, so it depends on the pattern and design.

Can I skip understitching when attaching facings?

While understitching is recommended for a polished finish, you can skip it. However, it may result in facings that are more prone to rolling to the garment’s exterior.

Can you use a different fabric for a facing?

Yes, a different fabric can be used for a facing, either for decorative contrast or when the primary fabric isn’t suitable for finishing edges.

To Recap

Facing in sewing is an indispensable technique that elevates the art of garment construction and textile craftsmanship. It serves as the bridge between the raw and the refined, seamlessly transforming frayed edges into a polished, professional finish.

Beyond its utilitarian purpose of preventing fraying and reinforcing seams, facings contribute significantly to a garment’s overall aesthetics. They enhance design elements, maintain shape, and add durability, ensuring that the finished creation not only looks impeccable but also stands the test of time.

Whether it’s a subtle interior reinforcement or a decorative accent, facings are a versatile tool that every sewing enthusiast should master, bringing precision, elegance, and a touch of artistry to their craft.

Leave a Reply