In sewing, fraying refers to the unraveling or loosening fabric fibers along the cut edges. It is a natural occurrence caused by factors such as fabric type, weave structure, and environmental conditions.

Fraying can compromise a garment’s durability and aesthetic appeal, leading to potential issues like unraveling hems or seams.

Various preventive measures, such as stitching techniques, seam finishes, and the use of specialized tools like pinking shears or sergers, are employed to mitigate fraying and ensure the longevity of sewn creations.

Understanding the causes and implementing effective solutions is crucial for achieving professional and enduring sewing projects.

What Is Fraying In Sewing?

In sewing, fraying refers to the unraveling or splitting fabric threads along the edges of a cut piece of material. It is a common issue that can occur when the fabric is cut, exposing the raw edges to the risk of unraveling over time.

Fraying is more likely to happen with fabrics that have a loose weave or are prone to fraying, such as cotton, linen, or certain synthetic materials.

To prevent fraying, seamstresses often employ various techniques. One common method is to apply a seam finish, such as zigzag stitching, serging, or using pinking shears, to the raw edges of the fabric.

These techniques create a barrier that helps secure the threads and inhibit fraying. Additionally, using fabric stabilizers or adhesives can further reinforce the edges.

Properly addressing fraying enhances the durability of the garment or project and contributes to a neater and more professional-looking finish.

What Causes Fabric to Fray?

Fabric fraying is a common issue that occurs when the threads along the edges of a fabric start to unravel and become loose.

Several factors contribute to fabric fraying, and understanding these causes can help prevent or minimize the problem.

Here are some key reasons why fabric tends to fray:

Quality of Fabric

The quality of fabric is determined by factors such as thread count, fiber type, and weaving techniques. Fabrics with a higher thread count generally have a tighter weave, making them more durable and less prone to fraying.

Moreover, fine natural fibers like cotton and silk often result in a smoother and more resistant surface, reducing the likelihood of fraying compared to coarser fibers.

Fabric Type

Different types of fabrics exhibit varying degrees of susceptibility to fraying. For instance, denim and canvas are known for their sturdy construction, making them less prone to unraveling.

In contrast, lightweight fabrics like chiffon or loosely woven materials like burlap are more susceptible to fraying due to their inherently delicate structures.

Weave Structure

The weave structure of a fabric significantly impacts its tendency to fray. Fabrics with a tight weave, such as plain or twill weaves, offer more resistance to fraying.

Twill weaves, characterized by a diagonal pattern, provide additional strength and stability. On the other hand, open weaves, like those found in mesh fabrics, may unravel more easily.

Fabric Cut

The precision of the fabric cut is crucial in determining how susceptible it is to fraying. Straight and clean cuts made along the grain of the fabric reduce the likelihood of fraying.

Conversely, jagged or uneven cuts, especially against the grain, create weak points where fraying is more likely to initiate.

Washing and Handling

The way a fabric is cared for can impact its longevity and susceptibility to fraying. Harsh washing practices, such as using strong detergents, high temperatures, or aggressive machine cycles, can weaken the fibers over time.

Gentle washing, preferably in cold water, and avoiding excessive agitation can help maintain the fabric’s integrity.

Exposure to Abrasion

Areas of the fabric subject to constant friction or abrasion, such as seams, cuffs, and collars, are more prone to fraying.

This can result from regular wear, especially in high-contact regions. Choosing appropriate fabrics for specific garment types and reinforcing vulnerable areas can help mitigate the effects of abrasion.

Lack of Finishing

The finishing processes a fabric undergoes can significantly affect its resistance to fraying. Serging, hemming, or using fray-resistant products can reinforce the edges, preventing loose threads from unraveling.

Fabrics lacking proper finishing are more likely to fray, especially along raw edges or seams.

Environmental Factors

External conditions can impact a fabric’s resilience over time. Exposure to sunlight, humidity, and extreme temperatures can accelerate the degradation of fabric fibers, making them more susceptible to fraying.

UV radiation, in particular, can weaken the molecular structure of fibers, leading to a gradual breakdown of fabric integrity.

How to Stop Fabric From Fraying?

Preventing fabric from fraying is essential to maintain the integrity and longevity of your textiles. Whether you’re working on a sewing project or trying to preserve the edges of a garment, several effective methods exist to stop fabric from fraying.

Here are some practical techniques:

Zigzag or Overlock Stitch

Sewing a zigzag or overlock stitch is a versatile technique that reinforces fabric edges, preventing fraying. Many modern sewing machines come equipped with built-in zigzag and overlock stitches, making it easily accessible.

Alternatively, a serger, a specialized sewing machine designed for edge finishing, can efficiently secure raw edges with a professional finish. The overlock stitch encases the raw edge in a series of loops, minimizing the risk of fraying.

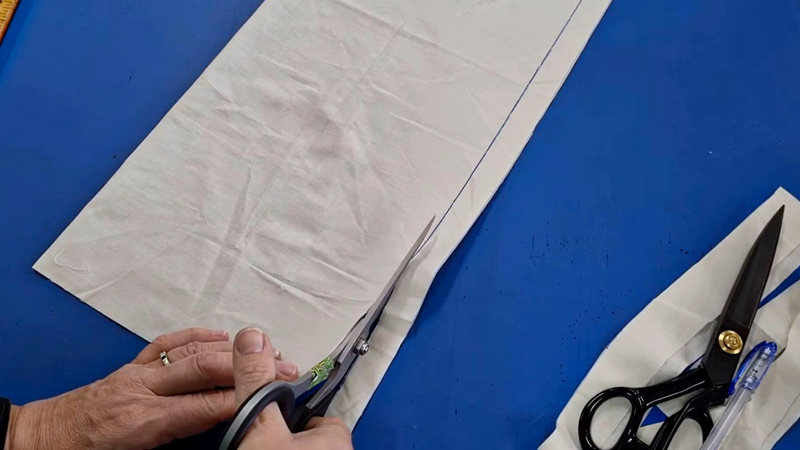

Pinking Shears

Pinking shears have serrated blades that create a zigzag pattern when cutting fabric. While not as secure as sewing, using pinking shears is a quick and accessible method to add a level of protection to fabric edges.

The zigzag cut disrupts the straight grain of the fabric, reducing fraying. This method is especially useful for lightweight fabrics where a bulkier stitched edge might be undesirable.

Hemming

Hemming involves folding the edge of the fabric over and stitching it in place, creating a clean and polished appearance.

This not only prevents fraying but also adds a decorative element. Hems can be simple, like a single or double-fold hem, or more elaborate, depending on the desired look and fabric type.

This method is commonly used in garment construction and is effective in preventing fraying on a wide range of fabrics.

Bias Tape or Binding

Applying bias tape or binding along raw edges effectively prevents fraying while adding a decorative touch.

Bias tape, cut on the diagonal grain for flexibility, is sewn along the edge, encasing and protecting it. This technique is often used for quilting, clothing, and home decor projects.

Bias tape comes in various widths and colors, allowing for customization based on the fabric and project requirements.

Fray Check or Fray Stop Liquid

Fray Check and similar fray stop liquids are commercial products designed specifically to prevent fraying.

These liquid sealants are applied directly to the raw edges of the fabric, forming a clear and flexible barrier that inhibits fraying.

Fray Check is particularly useful for delicate fabrics or intricate projects where traditional stitching may be challenging. Allow the liquid to dry completely before handling the fabric, ensuring a secure and durable finish.

Fabric Glue

Fabric glue is a convenient option for securing fabric edges and preventing fraying without the need for sewing. To use fabric glue, apply a small amount along the raw edge, ensuring even distribution.

Be cautious not to use too much, as excess glue may seep through the fabric. Allow the glue to dry thoroughly before handling or washing the fabric.

Fabric glue is particularly useful for quick fixes and projects where a stitched finish may not be suitable.

Seam Binding Tape

Seam binding tape is a narrow strip of fabric that can be sewn along raw edges to prevent fraying and provide a neat, finished appearance.

It is available in various colors and materials, allowing for customization to match or complement your fabric.

Seam binding tape is versatile and can be used on a variety of fabrics, making it a popular choice for both functional and decorative edge finishes.

Fusible Interfacing

Fusible interfacing is a stabilizing material that can be ironed onto the back of fabric. When applied to raw edges, it reinforces the fabric, preventing fraying.

This method is particularly beneficial for lightweight or delicate fabrics with undesirable bulky stitched edges.

Fusible interfacing is available in different weights and can be cut to match the fabric’s shape, providing an effective and discreet solution.

Fabric Sealant

Fabric sealants, similar to fray-stop liquids, come in spray form or aerosol cans. When sprayed or applied along the fabric edges, these sealants create a protective barrier, preventing fraying.

It’s important to ensure that the fabric is clean and dry before using a fabric sealant. This method is suitable for various fabrics and particularly useful for large projects or areas with intricate detailing.

Serging or Overlocking Machine

Serging or overlocking machines are specialized sewing machines designed to simultaneously trim and finish fabric edges.

These machines create a secure stitch that encases the raw edge with multiple threads, preventing fraying effectively.

Sergers are commonly used in garment construction and other sewing projects where a professional finish is desired. They are especially efficient when working with knit fabrics or projects with curved edges.

FAQs

What Does Frayed Clothing Mean?

Frayed clothing refers to garments where the fabric edges show signs of wear and tear, resulting in loose, unraveling threads.

This can occur due to repeated use, washing, or exposure to abrasion, causing the fabric fibers to break down and become frayed.

What Does Frayed Seams Mean?

Frayed seams indicate the unraveling or deterioration of stitched connections in fabric panels. This can happen over time due to frequent movement, seams’ stress, or poor construction.

Which fabrics are more prone to fraying?

Fabrics with a loose weave or delicate fibers, such as chiffon or muslin, are more prone to fraying.

Additionally, fabrics of lower quality or coarser texture may exhibit increased fraying tendencies.

Are there tools specifically designed to prevent fraying in sewing?

Yes, tools like pinking shears, sergers, and fabric sealants are specifically designed to prevent fraying in sewing.

These tools provide effective ways to finish raw edges and enhance the longevity of your sewing projects.

To Recap

Understanding the concept of fraying in sewing is essential for creating durable and aesthetically pleasing projects.

Fraying occurs when fabric fibers unravel along cut edges due to various factors like fabric quality, weave structure, and environmental conditions. This natural wear and tear can compromise the longevity and appearance of garments.

Employing preventive measures such as stitching techniques, seam finishes, and the use of specialized tools ensures that fraying is minimized or eliminated.

Seamstresses and hobbyists alike benefit from this knowledge, enabling them to produce high-quality creations that withstand the test of time and maintain a polished finish, enhancing the overall satisfaction and success of their sewing endeavors.

Leave a Reply