A front-loading sewing machine bobbin is a fundamental component of a sewing machine, integral to the process of creating stitches in fabric.

Unlike its top-loading counterpart, the front-loading bobbin is inserted into the sewing machine from the front, typically below the needle plate or within a removable bobbin case.

This bobbin houses the lower thread, which pairs with the upper thread to form stitches. Front-loading bobbins are often favored for their advantages in visibility, as users can easily monitor thread levels and detect potential issues like thread jams.

They are commonly found in older mechanical sewing machines and some specialized models, catering to various sewing needs.

Understanding how to work with a front-loading bobbin is essential for anyone engaged in sewing and textile crafting.

What Is Front Loading Sewing Machine Bobbin?

A front-loading sewing machine bobbin is a critical component of a sewing machine that plays a pivotal role in forming stitches.

It is located at the front of the machine, typically beneath the needle plate or throat plate, and holds the lower thread that interacts with the upper thread (threaded through the needle) to create a stitch.

Unlike top-loading bobbins, which are inserted from above, front-loading bobbins are loaded from the front of the machine, typically beneath the needle plate or within a removable bobbin case.

Front-loading bobbins are commonly found in older or mechanical sewing machines and some specialized models.

To thread the bobbin, the user places an empty bobbin onto a spindle, threads the thread through tension discs, and then guides it through a bobbin winding mechanism.

How a Front-Loading Sewing Machine Bobbin Functions?

A front-loading sewing machine bobbin functions through a precise series of steps to create the lower thread that, when combined with the upper thread, forms stitches in the fabric.

Here’s a step-by-step explanation of how it works:

Bobbin Placement

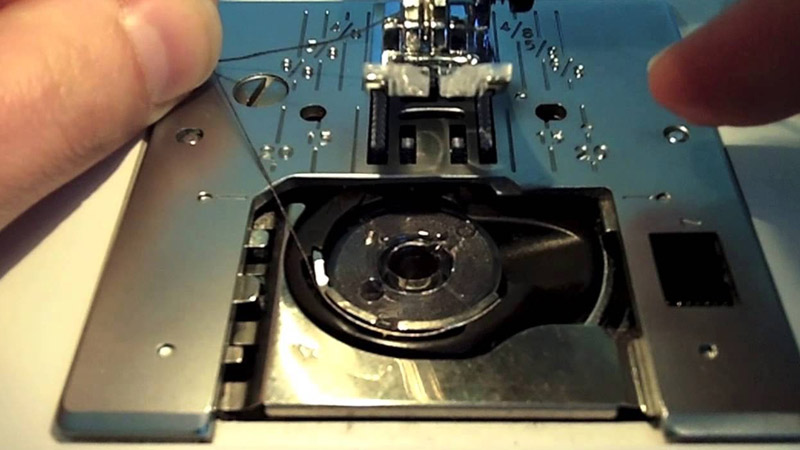

The bobbin placement in a front-loading sewing machine is typically beneath the needle plate, inside a bobbin case or holder.

This location ensures that the bobbin remains securely in place during sewing, allowing for precise stitching.

Threading the Bobbin

To begin the bobbin-loading process, you first need to position an empty bobbin onto a spindle at the top of the sewing machine.

Ensure that the thread passes through a small hole or guide on the bobbin. This threading step prepares the bobbin for winding.

Thread Tension Adjustment

Front-loading sewing machines come equipped with a thread tension control mechanism.

Adjust the tension settings to match the requirements of your specific sewing project. Proper tension ensures that the thread winds onto the bobbin evenly and at the right tightness.

Winding the Bobbin

With the empty bobbin in place and the thread properly guided through tension discs and other threading components, engage the sewing machine’s bobbin-winding feature.

When activated, the bobbin spindle turns, winding the thread neatly and uniformly onto the bobbin. You can monitor the bobbin-filling progress as you wind.

Bobbin Loading

After the bobbin is fully wound, carefully remove it from the spindle. To access the bobbin area for loading, open the front cover or slide the bobbin case cover, following your machine’s instructions.

Insert the wound bobbin into the bobbin case, ensuring that it’s oriented correctly, as indicated in your sewing machine’s manual.

Bobbin Threading

Thread the end of the bobbin thread through various guides and tension mechanisms within the bobbin case.

Proper threading ensures that the bobbin thread feeds smoothly and consistently during sewing, contributing to even and well-formed stitches.

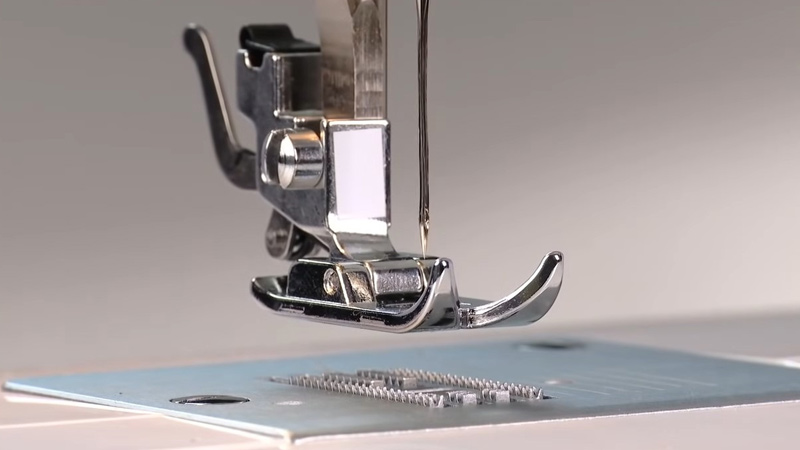

Stitch Formation

When you begin sewing, the sewing machine’s needle descends through the fabric. Simultaneously, it engages with the bobbin thread, which is positioned beneath the needle plate.

The bobbin thread is pulled up through the fabric by the motion of the needle, and the upper thread from the spool above interlocks with the bobbin thread. This interlocking action creates a secure and uniform stitch.

Continuous Operation

As you continue sewing, the sewing machine repeats the process rapidly, forming a continuous series of stitches.

These stitches combine to create the desired seam, hem, or decorative design on the fabric, depending on your chosen stitching pattern and sewing technique.

How to Insert(load) a Bobbin?

Inserting or loading a bobbin into a front-loading sewing machine requires careful attention to ensure smooth stitching.

Here’s a step-by-step guide on how to do it:

Turn Off the Machine

Ensure that your sewing machine is turned off before you begin. This safety precaution prevents any accidental needle contact.

Access the Bobbin Area

Open the front cover or slide the bobbin case cover to access the bobbin area. The location and method for accessing the bobbin area will depend on your sewing machine model.

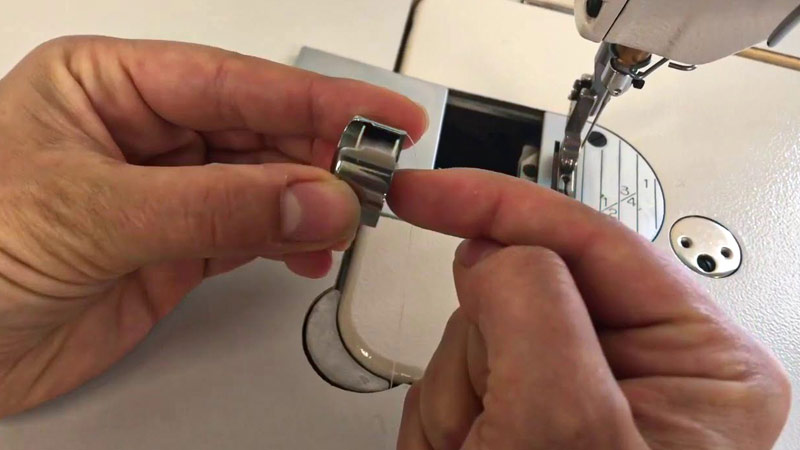

Remove the Bobbin Case

If your sewing machine has a removable bobbin case, gently remove it by following the instructions in your manual. Some machines have a hinged door that covers the bobbin area but doesn’t require removal.

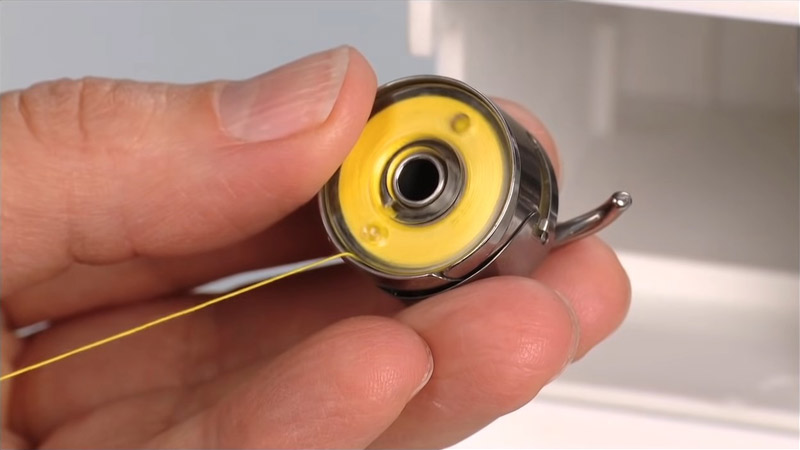

Prepare the Bobbin

Take the wound bobbin that you prepared earlier. Ensure that the thread end is hanging loose from the bobbin.

Insert the Bobbin

Hold the bobbin case or insert the bobbin, depending on your machine’s design. Make sure to follow the arrows or guides to position the bobbin correctly with the thread unwinding in the direction indicated in your manual. Proper placement is crucial for smooth stitching.

Thread the Bobbin

Guide the loose end of the bobbin thread through any necessary channels or guides within the bobbin case.

There may be tension mechanisms or slots designed to hold the thread in place. Be sure to follow the threading path outlined in your sewing machine’s manual.

Secure the Bobbin Case

If your sewing machine has a removable bobbin case, insert it back into its designated slot or holder, ensuring that it clicks or locks securely into place. If your machine has a hinged door, close it securely.

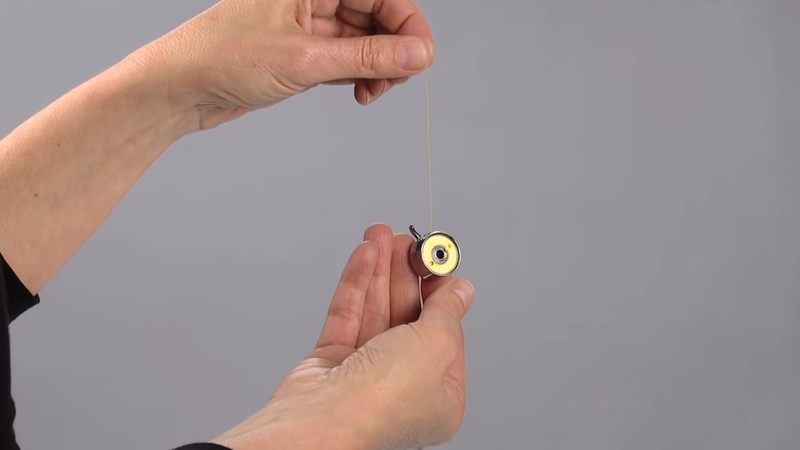

Pull Up the Bobbin Thread

Hold the upper thread (from the spool) with your hand and gently turn the handwheel toward you (usually found on the right side of the machine) to lower the needle into the bobbin area.

Continue turning the handwheel until the needle comes back up, pulling up a loop of the bobbin thread.

Retrieve the Bobbin Thread

Use a pair of tweezers, your fingers, or a small, blunt instrument to reach in and grab the loop of the bobbin thread. Pull it through the needle plate slot.

Drop-In Bobbin vs. Front Load

When it comes to sewing machines, the method of bobbin insertion can vary between different models and designs.

Two common types of bobbin insertion mechanisms are the “Drop-In Bobbin” and the “Front-Load Bobbin.”

Each of these systems has its own set of advantages and considerations, and understanding the differences between them can help you choose the right sewing machine for your specific needs.

Below, we provide a comparative table outlining the key characteristics of Drop-In Bobbin and Front-Load Bobbin systems:

| Feature | Drop-In Bobbin | Front-Load Bobbin |

| Ease of Installation | Very Easy | Relatively Easy |

| Visibility | High | Good |

| Bobbin Loading Location | Top of the Sewing Machine | Front of the Sewing Machine |

| Bobbin Case | Typically Not Removable | Removable (in a case) |

| Bobbin Threading | Simplified Process | Slightly More Complex |

| Bobbin Capacity | Typically Smaller | Typically Larger |

| Thread Monitoring | Easy to See | Requires Front Cover |

| Bobbin Changing Frequency | Frequent | Less Frequent |

| Suitable for Beginners | Yes | Yes |

| Maintenance | Less Prone to Tangles | May Require Cleaning |

| Common Sewing Machines | Many Home Sewing Machines | Older and Specialty Models |

Singer Bobbin Sizes Chart

Singer sewing machines come in various models, each with its own specific bobbin size. Bobbin sizes are not universal and can vary from model to model.

To determine the correct bobbin size for your Singer sewing machine, it’s essential to refer to your sewing machine’s manual or check the markings on your existing bobbins.

Below is a general chart of common Singer bobbin sizes:

| Singer Bobbin Size | Compatible Singer Sewing Machine Models |

| Class 15 (Transparent) | Singer 15, 66, 99, 127, 128, 192, and many more |

| Class 66 (Metal) | Singer 66, 99, 185, 192, 201, and more |

| Class 221/301 (Featherweight) | Singer 221 Featherweight, 301, and others |

| Class 18 (Metal) | Singer 206, 306, 319, and similar models |

| Class 27 (Metal) | Singer 27, 28, 127, and more |

| Class 28 (Metal) | Singer 27, 28, 127, and similar models |

| Class 66 (Transparent) | Singer 66, 99, 185, 192, and others |

| Class 29 (Metal) | Singer 29, 29-4, and similar models |

| Class 17 (Transparent) | Singer 50T8, 7256, 7258, and more |

FAQS

Is a front-loading bobbin compatible with all sewing machines?

Front-loading bobbins are not universally compatible with all sewing machines.

Are front-loading bobbins more prone to jamming than top-loading bobbins?

Front-loading bobbins are not necessarily more prone to jamming, but if not threaded correctly or if the bobbin case is not inserted properly, they can cause sewing issues.

Can I use different types of thread in a front-loading bobbin?

Yes, you can use various types of thread in a front-loading bobbin, including polyester, cotton, and specialty threads.

Is it possible to convert a front-loading sewing machine to use a top-loading bobbin?

Converting a sewing machine from front-loading to top-loading or vice versa is a complex task and typically requires professional modification.

Do front-loading bobbins work well with heavy fabrics and thick threads?

Front-loading bobbins can handle heavy fabrics and thick threads, but you may need to adjust the tension settings and choose appropriate needles to accommodate the thickness of the materials.

To Recap

The front-loading sewing machine bobbin is a vital component in the world of sewing, providing precision and control in stitch formation.

Its unique loading mechanism, inserted from the front of the machine, distinguishes it from top-loading bobbins.

This design choice offers clear advantages in terms of visibility and access, making it a popular choice for tasks demanding meticulous work like embroidery and quilting.

While it may require more frequent bobbin changes, the front-loading system ultimately ensures greater stitch accuracy.

Whether you’re a seasoned seamstress or a novice sewist, understanding the front-loading sewing machine bobbin and its functioning is key to achieving professional-grade results in your sewing endeavors.

Leave a Reply