Fusible interfacing is a vital element in sewing, serving as a fabric with a transformative quality.

Defined by its heat-activated adhesive, this specialized material enhances the structural integrity of garments by providing stability and shape.

Whether woven or non-woven, fusible interfacing offers versatility in application, with each type tailored to different fabric weights and project requirements.

Its seamless integration involves a simple ironing process, making it an accessible choice for novice and experienced sewers.

Embraced for its invisibility on the fabric’s right side and varied weight options, fusible interfacing is an indispensable tool, contributing to the professional finish and longevity of sewing projects.

What Is Fusible Interfacing in Sewing?

Fusible interfacing is a specialized fabric with a heat-activated adhesive used in sewing to add structure and stability to garments.

With one side featuring a heat-activated adhesive, it bonds permanently to fabric through ironing.

This versatile tool comes in woven or non-woven varieties, each with specific characteristics suitable for different fabrics and projects. Fusible interfacing is valued for its ease of application, durability, and invisibility on the right side of the fabric.

Available in various weights, it caters to diverse sewing needs, supporting areas like collars, cuffs, and plackets while preventing fraying and maintaining a professional finish.

How Does Fusible Interfacing Work? 5 Following Steps

Fusible interfacing works through a heat-activated adhesive applied to one side of the fabric. The process involves the following steps:

1. Adhesive Coating

Fusible interfacing has a side coated with a heat-activated adhesive. This adhesive is usually a resin or polymer that remains solid at room temperature but softens and becomes tacky when exposed to heat.

2. Application to Fabric

The fusible interfacing is placed on the fabric, with the adhesive side facing down onto the wrong side of the fabric. The side without the adhesive is usually smoother and may have a grid or other markings.

3. Heat Activation

The fabric and interfacing are pressed together using an iron set to the appropriate temperature. The heat from the iron activates the adhesive, causing it to soften and bond with the fabric.

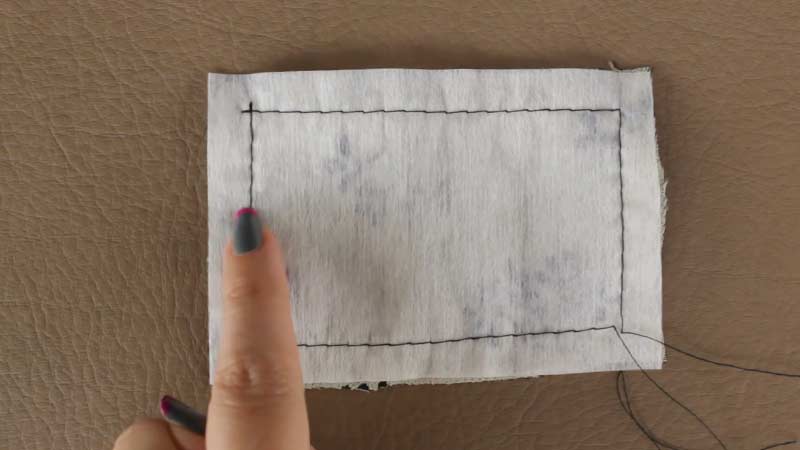

4. Bonding Process

As the adhesive softens, it adheres to the fabric’s fibres, creating a strong and permanent bond. The heat ensures that the interfacing becomes an integral part of the fabric, adding structure and stability.

5. Cooling Period

After application, it is crucial to let the interfacing cool completely. During this cooling period, the adhesive solidifies, establishing a durable connection between the interfacing and fabric.

Why Is Fusible Interfacing Used in Sewing Projects?

Fusible interfacing is crucial in sewing, serving multiple purposes to enhance the quality and appearance of finished garments and fabric projects.

Here’s a closer look at why fusible interfacing is a valuable tool in sewing projects:

Structure and Stability

One of the primary purposes of fusible interfacing is to provide additional structure and stability to fabrics. It is applied to specific areas of a garment or project to ensure that those areas maintain their shape and do not deform over time.

Reinforcement

Fusible interfacing reinforces certain elements of a garment, such as collars, cuffs, plackets, and waistbands. Adding a layer of interfacing makes these components more rigid and less prone to wrinkling or sagging.

Preventing Stretch

In fabrics that are susceptible to stretching or distortion, fusible interfacing helps prevent these undesirable effects. It stabilizes the fabric and maintains its original dimensions, especially with lightweight or loosely woven materials.

Preventing Fraying

Fusible interfacing helps prevent fraying along fabric edges. This is particularly useful for fabrics that tend to fray easily, ensuring the longevity and durability of the finished product.

Enhancing the Appearance

By providing structure and reinforcement, fusible interfacing contributes to a sewing project’s overall polished and professional appearance. It helps achieve a clean and well-defined look, especially in areas that require a crisp finish.

Versatility

Fusible interfacing is versatile and can be used for various sewing projects. It comes in different types and weights, making it suitable for delicate fabrics and heavier materials.

This versatility allows sewers to customize their approach based on the specific requirements of each project.

Ease of Application

One significant advantage of fusible interfacing is its ease of application. An iron is applied to activate the adhesive on one side of the interfacing, creating a permanent bond with the fabric.

This eliminates the need for sewing the interfacing in place, saving time and effort.

Durable Bond

Fusible interfacing creates a durable bond with the fabric, ensuring it withstands washing and wearing over time. The adhesive forms a secure connection, preventing the interfacing from detaching or losing effectiveness after repeated use.

Invisible Support

When applied correctly, fusible interfacing is often invisible on the right side of the fabric. This allows for the addition of support and structure without altering the visual appearance of the finished garment.

Types of Fusible Interfacing in Sewing

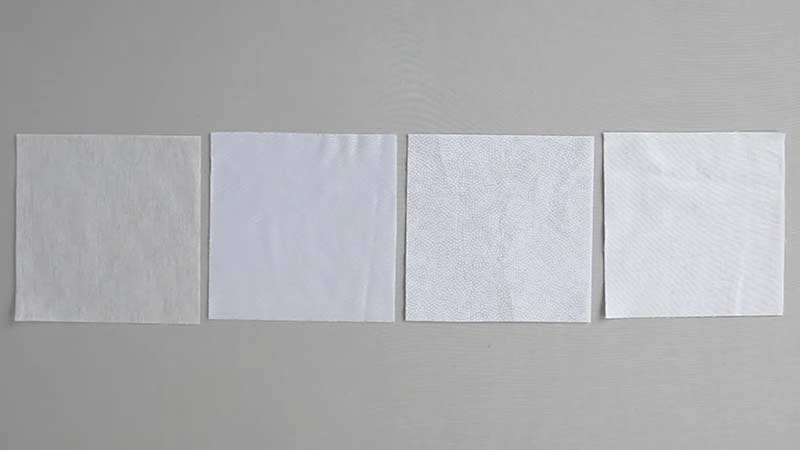

Fusible interfacing comes in various types, each designed to cater to different fabrics and project requirements.

Here are the main types of fusible interfacing in sewing:

1. Woven Fusible Interfacing

With its distinctive grain line, woven fusible interfacing adds a touch of flexibility and drapability to light to medium-weight fabrics. It is ideal for collars and cuffs and maintains a delicate balance between structure and ease of movement.

2. Non-Woven Fusible Interfacing

Non-woven fusible interfacing, lacking a specific grain line, brings stability and stiffness to medium to heavy-weight fabrics.

Its versatile nature allows unrestricted cutting, making it suitable for various applications where added structure is essential.

3. Knit Fusible Interfacing

Tailored for knit fabrics, knit fusible interfacing introduces a stretchy companion that supports the fabric’s inherent elasticity.

Perfect for projects involving stretchy materials like T-shirts or jersey dresses, it ensures structural integrity without compromising flexibility.

4. Sheer or Transparent Fusible Interfacing

Crafted from lightweight, translucent materials, sheer or transparent fusible interfacing delicately supports sheer fabrics.

Virtually invisible on the right side of the fabric, it maintains the ethereal drape of delicate materials like organza and lightweight silks.

5. Tricot Fusible Interfacing

Tricot fusible interfacing, hailing from a fine warp-knit fabric, offers a hint of stretch and lightweight support. Often found in activewear and projects requiring fabric flexibility, it easily complements stretchy materials.

6. Fusible Interfacing with Adhesive on Both Sides

With adhesive on both sides, this interfacing eliminates the need for sewing by facilitating the bonding of two fabrics. Perfect for appliqué work and projects requiring a secure bond on both sides, it adds versatility to construction methods.

Benefits of Using Fusible Interfacing in Sewing

Using fusible interfacing in sewing projects offers several benefits that contribute to the overall quality and appearance of the finished items.

Here are some key advantages:

Ease of Application

Fusible interfacing simplifies the sewing process with its easy application method. Using just an iron and a pressing cloth, sewers can effortlessly bond the interfacing to the fabric, saving time and effort compared to traditional sew-in methods.

Durability

The heat-activated adhesive in fusible interfacing creates a robust bond with the fabric, ensuring durability even after washing and regular use. This longevity adds to the overall quality and resilience of the finished garment or project.

Versatility

Fusible interfacing proves its versatility from collars to pockets by catering to many sewing projects. Its availability in various types and weights makes it adaptable to different fabric types and project requirements.

Invisibility

When applied correctly, fusible interfacing remains inconspicuous on the right side of the fabric. This invisible support allows the natural beauty of the fabric to take centre stage without any visible alterations.

Prevention of Fraying

Fusible interfacing acts as a protective barrier, preventing fraying along fabric edges. This feature is particularly beneficial for fabrics prone to unravelling, enhancing the overall longevity and neatness of the sewing project.

Structure and Shape

Crucial for maintaining the structure of collars, cuffs, and other garment elements, fusible interfacing ensures a crisp and defined appearance. It contributes to the professional finish of garments, adding a touch of refinement.

Weight Options

The availability of different weights—light, medium, and heavy—allows sewers to tailor their choice based on the specific fabric and project requirements. This flexibility ensures optimal support without compromising the desired drape or flexibility of the fabric.

Compatibility with Various Fabrics

Fusible interfacing’s compatibility spans various fabrics, from delicate silks to sturdy denims. Its ability to adapt to different fabric types makes it an essential tool for sewers working on diverse projects.

How to Choose the Right Fusible Interfacing for Your Sewing Project?

Choosing the right fusible interfacing for your sewing project is crucial to achieving the desired outcome. Here are some considerations to help you select the appropriate fusible interfacing:

Consider Fabric Type and Weight

Match the weight of the interfacing to the weight of your fabric. For lightweight fabrics like silk or chiffon, use light interfacing. For heavier fabrics like denim, opt for heavy interfacing.

Identify the Project’s Purpose

Consider the role of the interfacing in your project. Different projects may require specific types of interfacing. For example:

- Collars and cuffs may benefit from a medium-weight woven interfacing for added structure.

- Light, non-woven interfacing may be suitable for hems or appliqués where a soft drape is desired.

Check the Manufacturer’s Recommendations

Review the manufacturer’s instructions on the interfacing packaging. Manufacturers provide guidelines on the type of fabrics the interfacing is suitable for and recommended application methods.

Understand Woven vs. Non-Woven Interfacing

Consider the characteristics of woven and non-woven interfacing. Woven interfacing has a grain line and is more flexible, while non-woven interfacing is generally stiffer. Choose based on the desired level of flexibility and stability.

Evaluate Fabric Stretch

If you’re working with knit fabrics that have stretch, choose a knit fusible interfacing. This type of interfacing complements the stretch in knit fabrics while providing stability.

Think About Sheerness

Consider using sheer or transparent fusible interfacing for sheer fabrics like organza or lightweight silks. This type is lightweight and won’t compromise the delicate appearance of sheer fabrics.

Consider Project Complexity

Evaluate the complexity of your project. For intricate designs, choose interfacing that complements the details. Lighter interfacing may be suitable for detailed work, while heavier interfacing provides structure for larger elements.

Check for Adhesive on Both Sides

If your project involves bonding two fabrics together without sewing, consider using fusible interfacing with adhesive on both sides. This is ideal for appliqué work or projects where a secure bond on both sides is necessary.

Think About Washing Requirements

Consider the care requirements of your fabric and interfacing. If your fabric requires pre-washing, ensure that both the fabric and interfacing are pre-washed to prevent any issues with shrinkage or distortion later.

Consult Sewing Resources

Check sewing books, online forums, or tutorials for recommendations. Experienced sewers often share insights into the best interfacing choices for specific fabrics or projects.

FAQs

Can fusible interfacing be used on all types of fabrics?

Fusible interfacing is versatile and suitable for a wide range of fabrics. However, choosing the right type and weight based on the fabric’s characteristics is crucial for optimal results.

Does fusible interfacing affect the drape of the fabric?

The impact on the drape depends on the interfacing’s weight. Light-weight interfacing adds minimal crispness, preserving the drape, while heavy-weight interfacing provides more structure, potentially affecting the drape.

How do you apply fusible interfacing correctly?

Apply fusible interfacing by pre-washing fabric, cutting interfacing to size, placing it on the fabric’s wrong side, pressing with an iron using a pressing cloth, and allowing it to cool completely before handling.

Can fusible interfacing be removed once applied?

Once fusible interfacing is applied and bonded, it is challenging to remove without damaging the fabric. Careful consideration and testing before application are recommended.

How long does the bonding effect of fusible interfacing last?

When applied correctly, the bonding effect of fusible interfacing lasts for the garment’s life. Proper care during washing and ironing helps maintain the durability of the bond.

To Recap

Fusible interfacing emerges as a linchpin in sewing, elevating garments from mere fabric to structured, polished creations. It is indispensable in adding stability, preventing fraying, and shaping specific elements like collars and cuffs.

The ease of application, durability, and versatility across fabric types make it a go-to choice for sewers of all levels. The invisible support it provides and its varied weight options empower creators to tailor their projects precisely.

Fusible interfacing, with its heat-activated magic, not only simplifies the sewing process but contributes significantly to the longevity and professional appeal of the final product, marking it as an essential tool in every sewing toolkit.

Leave a Reply