If you’ve been knee-deep in a sewing project, you may have encountered the term ‘interlining.’ It’s one of those jargon that can leave beginners scratching their heads.

So, what is interlining? Simply put, interlining is an additional layer of fabric sandwiched between the outer material and lining. It aims to provide extra body, support, and warmth to your garments or home decor items.

Interlining fabric varies widely. You’ll find lightweight materials like silk or cotton for delicate creations, while thicker fabrics like wool are used for heavier applications. The choice of interlining fabric largely depends on your project’s desired structure and warmth.

The sewing world also introduces us to fusible interlinings, which add a convenient twist to traditional interlinings. Fusible interlinings have an adhesive side that binds directly with the fabric when heated, simplifying the process further.

Whether you’re making drapes or winter coats, understanding how different types of interlinings work can be a game-changer in your sewing journey.

Definition of Interlining in Sewing

Peering into the world of sewing, there’s a term that stands out: interlining. So, what is interlining? Well, I’m here to make it clear to you.

Interlining is an extra layer of fabric between the outer material and garment lining. It’s sandwiched between the two fabrics to provide added structure or warmth. It’s often used in tailored jackets, coats, or even curtains because of its unique properties.

There are various types of interlining fabrics available depending on your specific needs. Fusible interlinings, for example, have adhesive on one side so they can be ironed directly onto your fabric.

This makes them a popular choice for many sewers as it provides a quick and easy method to add body to thinner materials.

But don’t think all interlinings are fusible! Some styles require stitching into place, allowing more flexibility during fitting but taking a bit longer to secure.

Let me tell you about my experience using these different types – I took up this denim jacket project last year.

The material was relatively thin, so I decided to use fusible interlining. Boy, oh boy! The transformation was incredible! It gave my jacket the right amount of structure without making it stiff.

Understanding the definition and applications of interlining can elevate your sewing projects from good to great!

Whether working with lightweight summer dresses or heavy winter coats, knowing when and how to use this hidden hero can help you achieve professional results every time!

5 Key Reasons Why Interlining Holds Importance in Sewing

Interlining is pivotal in sewing, offering many benefits that contribute to the quality, durability, and aesthetic appeal of garments and home decor items.

Here are some key reasons why interlining is indispensable:

1. Structural Integrity

Interlining reinforces fabrics, particularly those that are lightweight or prone to stretching.

By sandwiching an additional layer of fabric between the main layers, interlining adds stability and prevents distortion, ensuring that garments maintain their shape and structure over time.

2. Enhanced Drapability and Body

In garment construction, interlining can significantly impact how fabric drapes and falls on the body. By adding body and weight to fabrics, interlining creates a smoother silhouette and enhances the overall fit of the garment.

This is particularly beneficial for achieving tailored looks and structured designs.

3. Improved Comfort and Wearability

Beyond structural benefits, interlining can enhance the comfort and wearability of garments. For example, interlining materials such as fleece or quilted fabrics in outerwear provide insulation against cold weather, keeping the wearer warm and cozy.

Additionally, interlining can add a layer of softness between the skin and outer fabrics, enhancing comfort during wear.

4. Aesthetic Enhancement

Interlining contributes to the visual appeal of sewing projects by improving the appearance and finish of garments and home decor items. It can add depth and richness to fabrics, creating a luxurious look and feel.

In curtains and draperies, interlining adds fullness and body, giving them a more elegant and polished appearance.

5. Versatility and Adaptability

Interlining comes in various forms, including sew-in, fusible, and adhesive options, offering versatility in application. Sewers can choose the most suitable interlining type based on their project’s fabric, design, and desired outcome.

This adaptability makes interlining suitable for various sewing applications, from delicate couture garments to sturdy upholstery.

Exploring Common Types of Interlining Materials

Interlining materials are essential in sewing, offering structural support, and enhancing the quality of finished projects.

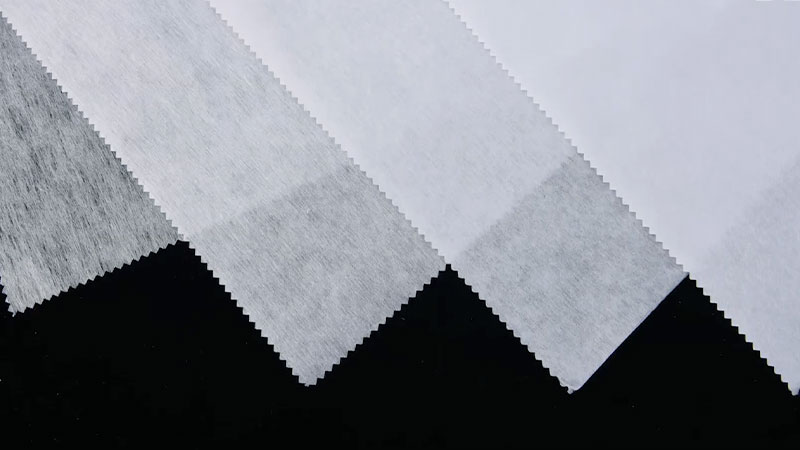

Here’s an overview of some common types of interlining materials frequently used by sewers:

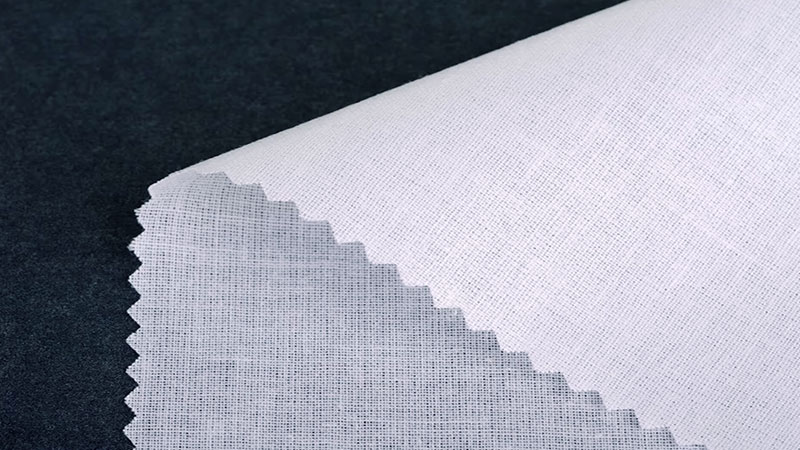

Woven Interlinings

Woven interlinings are crafted by weaving threads together, creating a sturdy and flexible fabric. These interlinings provide excellent structural support while allowing garments to maintain flexibility and movement.

They are often utilized in tailored garments such as blazers, coats, and suits, where maintaining shape is crucial.

Fusible Interlinings

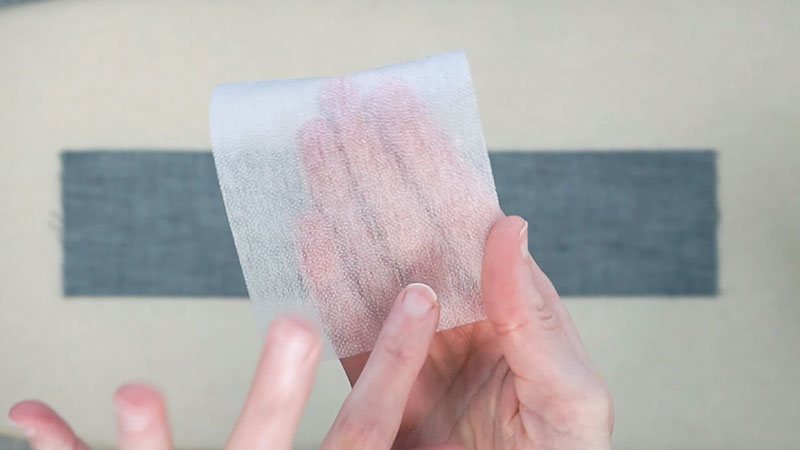

Fusible interlinings feature adhesive on one side that activates when heated, allowing for easy fabric attachment. This type of interlining is favored for its convenience and stability without adding bulk.

Fusible interlinings are commonly used in projects requiring precise shapings, such as shirt collars, cuffs, and button plackets.

Knitted Interlinings

Knitted interlinings are softer and more pliable than woven varieties, making them suitable for lightweight and flexible garments.

These interlinings offer excellent drapability and are often used in garments with flowing silhouettes, such as t-shirts, dresses, and lightweight jackets.

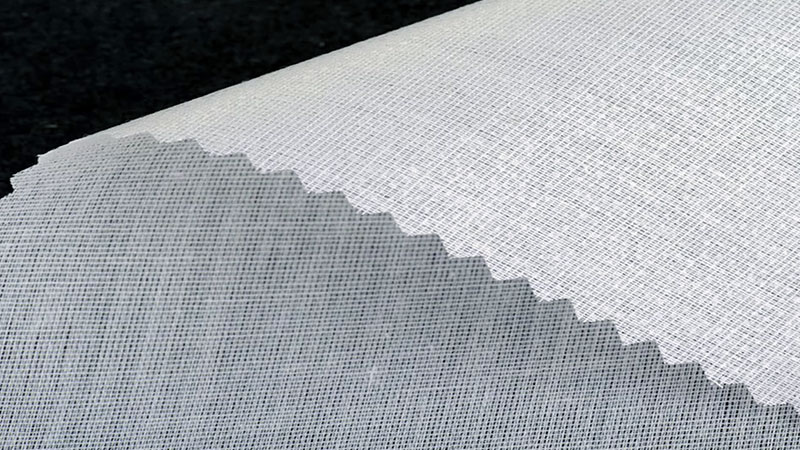

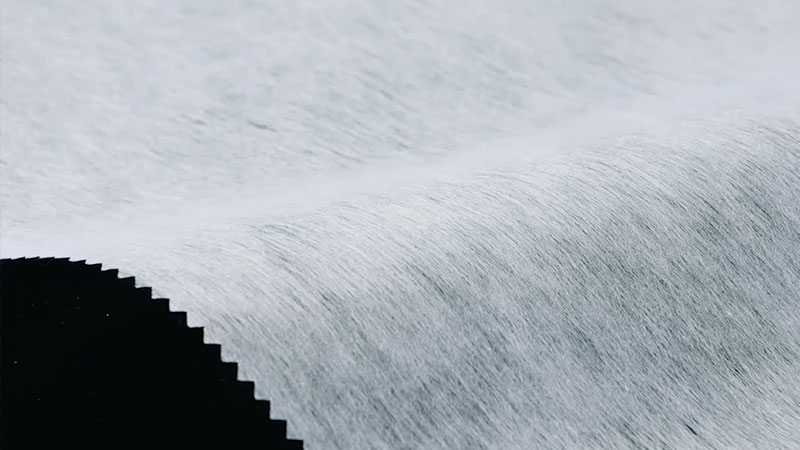

Non-Woven Interlinings

Non-woven interlinings are created by fusing fibers using heat or chemicals rather than weaving threads. This results in a versatile material varying in thickness and weight, offering options for different sewing projects.

Non-woven interlinings can be either sewn-in or fusible, providing flexibility in application.

How Do You Choose the Right Interlining for Your Project?

Choosing the appropriate interlining fabric is crucial for achieving your sewing projects’ desired structure, warmth, and durability.

Here’s a step-by-step guide to help you select the perfect interlining for your specific needs:

Determine the Purpose of Your Project

Consider the intended use of your garment or item. Opt for heavier interlinings for drapery or upholstery projects to add volume and enhance durability.

For delicate garments like blouses or dresses, choose lightweight interlinings to maintain fluidity and avoid weighing down the fabric.

Ensure Compatibility

Ensure that the chosen interlining fabric complements your main fabric in weight, texture, and color. Compatibility is essential for achieving a cohesive and professional-looking finish.

Additionally, consider how the interlining will interact with your main fabric, especially if using fusible interlinings, as different fabrics may react differently to heat.

Consider Maintenance Requirements

Take into account the maintenance needs of your project. If the item requires frequent washing or dry cleaning, opt for machine-washable interlinings that can withstand repeated laundering without losing shape or integrity.

Sew-in interfacing is a durable option for items subjected to regular washing, such as reusable bags or table runners.

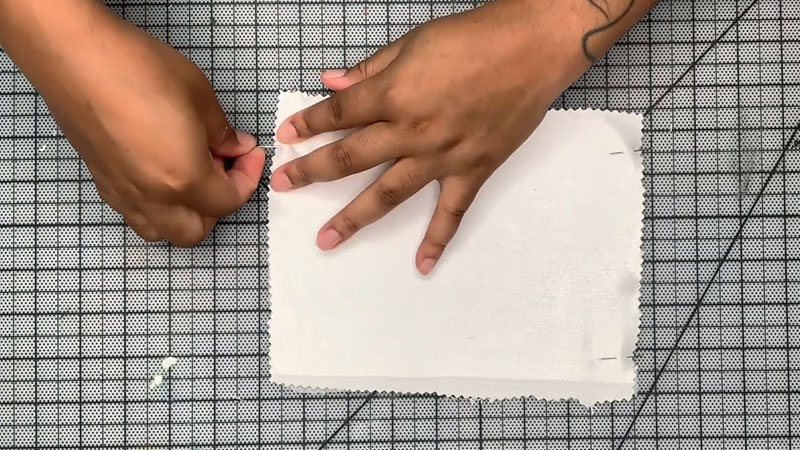

Experiment and Practice

Don’t hesitate to experiment with different types of interlinings on scrap fabric before committing to your final project. This allows you to test each interlining type’s compatibility, drape, and overall effect, helping you make an informed decision.

Practice builds confidence and enables you to understand the characteristics of various interlining materials better.

Evaluate Results and Adjust as Needed

After incorporating the chosen interlining into your project, evaluate the results and make any necessary adjustments. Pay attention to the overall structure, drape, and appearance of the finished piece, and make note of any areas for improvement.

This feedback will inform your future interlining choices and enhance your sewing skills over time.

How to Apply Interlining in Sewing? Step-by-Step Guide

Interlining is critical in achieving structural integrity and improving the quality of your sewing projects. Whether you’re using fusible or non-fusible interlinings, here’s a step-by-step guide to applying them effectively:

Choose the Right Interlining

Select the appropriate interlining fabric based on your project requirements. Fusible interlinings are ideal for beginners due to their ease of application, while non-fusible interlinings require basting stitches for attachment.

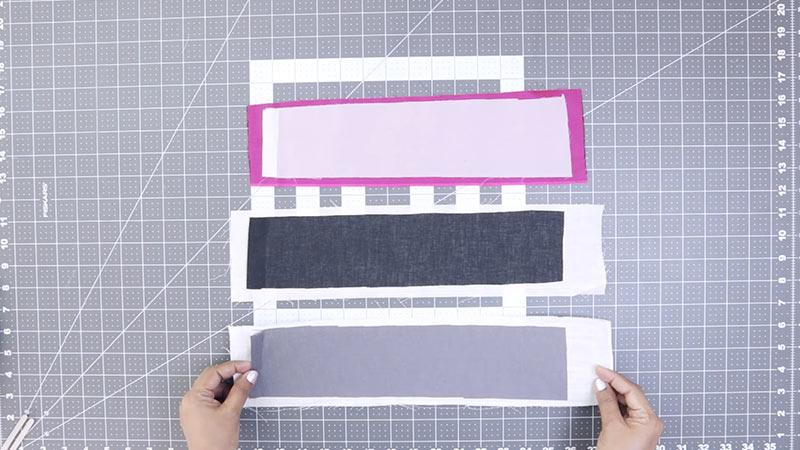

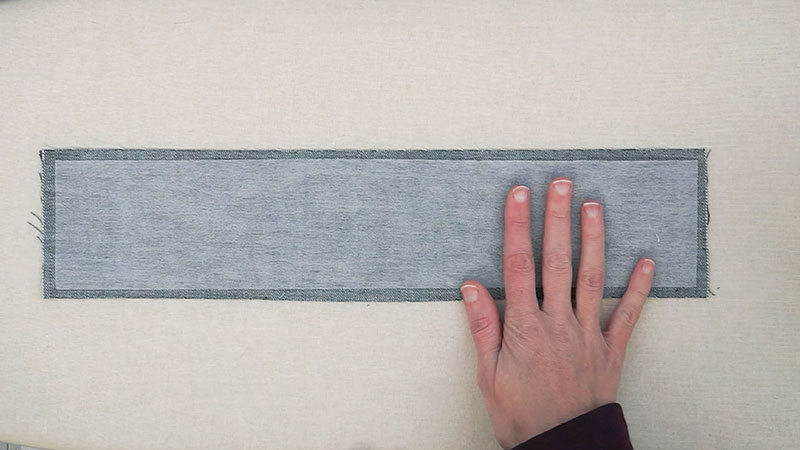

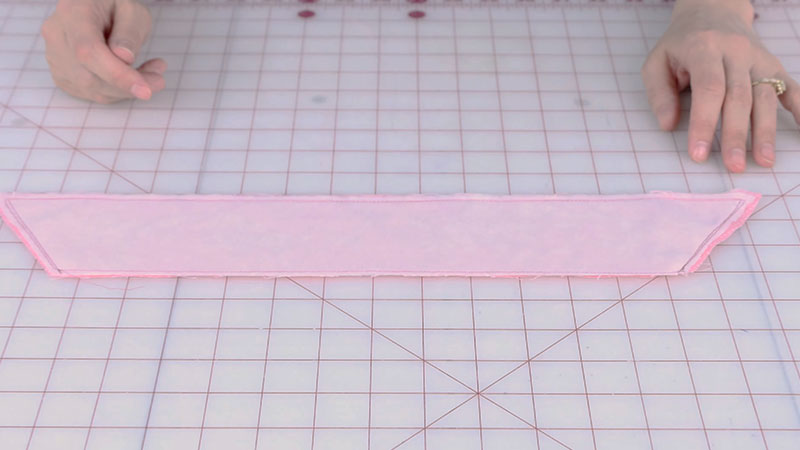

Prepare Your Materials

Cut out your pattern pieces from your main and interlining fabric, ensuring they are identical in size and shape.

Apply Fusible Interlining

For fusible interlinings, place the adhesive side (rough side) of the interlining onto the wrong side of the corresponding main fabric piece. Ensure proper alignment and smooth out any wrinkles or creases.

Fuse Interlining to Main Fabric

Using a hot iron set to the appropriate temperature (typically specified on the interlining packaging), press down firmly on each area of the interlining for about 10 seconds. Work systematically to ensure even adherence across the entire surface.

Exercise Patience

Take time during the fusing process to avoid rushing and ensure proper adhesion. Rushing can lead to poorly adhered areas, which may result in bubbling or wrinkling later.

Secure Non-Fusible Interlining

For non-fusible interlinings, use basting stitches to secure the interlining onto the wrong side of the main fabric. Space the stitches evenly around the edges of the interlining to prevent shifting during construction.

Proceed with Construction

Once the interlining is securely attached to the main fabric, proceed with the construction of your project as per your pattern instructions. Sew carefully around the edges of the interlining to avoid puckering or distortion.

Final Touches

After completing the construction, press the seams and any remaining interlining gently with an iron to ensure smoothness and crispness in the finished garment.

To Recap

Having delved deep into the sewing world, I’ve genuinely appreciated the hidden hero of many projects: interlining fabric. This unsung warrior provides stability, shape, and often a touch of luxury that’s hard to achieve otherwise.

What is interlining? It’s an additional layer applied between a garment or project’s outer material and lining. The type chosen – fusible interlinings or sew-in versions – can significantly alter the final look and feel.

Here are some critical points about interlining fabrics:

- They provide added body and structure

- They can improve drape and hang in garments

- They’re available in various weights for different effects

- Fusible interlining adheres directly to your fabric using heat

Choosing an appropriate interlining may seem daunting. However, it becomes more straightforward with a clear understanding of your project requirements.

Remember:

- Lighter fabrics often pair well with lighter-weight interlinings

- Heavier materials might require more substantial support from their counterpart

The power that lies within this seemingly simple addition is fascinating! When used effectively, it has the potential to take your sewing projects from good to great, transforming them into pieces you’re proud to show off.

So, next time you contemplate your next creation, don’t forget the importance of correctly utilizing this hidden gem. Interlining just might be the secret ingredient you’ve been missing all along!

In conclusion (without starting my sentence with ‘in conclusion’), understanding what interlines in sewing allows us to appreciate its role in our creations better.

Whether it’s fusible or sewn-in, heavy-duty or lightweight – every piece plays its part in crafting something beautiful.

Leave a Reply