The rotary hook shuttle is a fundamental and ingenious component within sewing machines, serving as the heart of the stitching process.

Its significance lies in its ability to create precise and uniform stitches, essential for achieving professional-quality sewing results.

Unlike other shuttle mechanisms, the rotary hook shuttle offers exceptional efficiency and speed, making it a favored choice in various sewing applications.

This critical technology operates quietly, reduces thread breakage, and is versatile enough to handle a wide range of fabrics and thread types.

In this exploration, we delve into the world of the rotary hook shuttle, examining its inner workings, advantages, and pivotal role in the art of sewing.

The Definition of Rotary Hook Shuttle in Sewing Machine

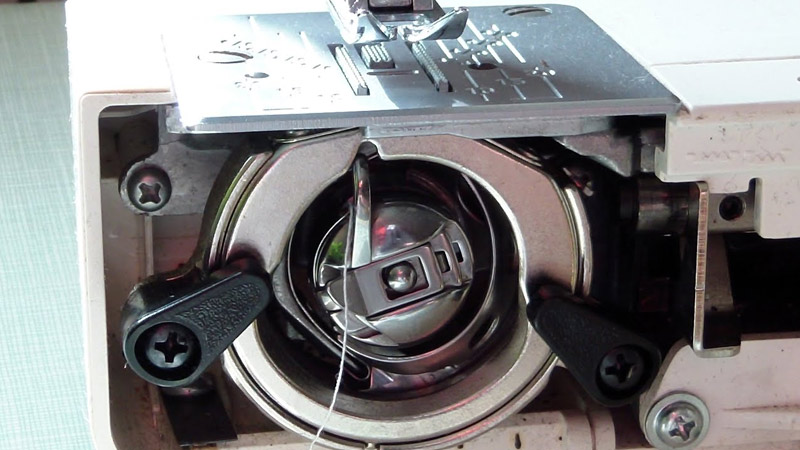

A rotary hook shuttle is a critical component in a sewing machine, playing a pivotal role in the stitching process.

This ingenious mechanism is responsible for forming stitches by interlocking the top thread, typically coming from the needle, with the bobbin thread, which is wound around the bobbin.

Unlike oscillating shuttles, rotary hook shuttles function in a circular or rotary motion, hence their name. The rotary hook shuttle comprises a hook that rotates around a central axis.

As the machine operates, the hook catches the top thread’s loop and carries it around the bobbin, where it intertwines with the bobbin thread, creating a secure and uniform stitch.

This rotary action allows for precise and efficient stitching, making it a preferred choice in many sewing applications.

Rotary hook shuttles are commonly found in industrial sewing machines due to their reliability and speed.

They contribute to the production of high-quality, consistent stitches and are essential in various industries, including apparel manufacturing, automotive upholstery, and more.

Their precise and rapid stitching capability makes them a cornerstone of modern sewing technology.

Functions of Rotary Hook Shuttle in Sewing Machine

The rotary hook shuttle in a sewing machine serves several crucial functions, all of which contribute to the creation of well-formed and durable stitches.

These functions make it an essential component in sewing machines, especially in industrial and heavy-duty applications.

Here are the primary functions of a rotary hook shuttle:

Thread Interlocking

The rotary hook shuttle’s primary purpose is to precisely interlock the top thread and bobbin thread. This interlocking action creates a secure and balanced stitch formation.

This function ensures that the stitches remain intact even under stress, making them ideal for sewing tasks that require durability.

Stitch Formation

Rotary hook shuttles are particularly adept at creating consistent and well-defined stitches. The precision of their rotary motion contributes to the uniformity of stitches, resulting in aesthetically pleasing and structurally sound seams.

This is especially important in applications where appearance and strength are critical, such as garment manufacturing and automotive upholstery.

Speed and Efficiency

The rotary hook shuttle’s continuous circular motion enables sewing machines to operate at high speeds without sacrificing stitch quality.

This speed and efficiency are invaluable in production settings where maximizing output while maintaining quality is essential. It ensures that projects are completed quickly and efficiently.

Versatility

Rotary hook shuttles are versatile and adaptable to a wide range of sewing materials and threads.

They can handle various fabric types, from delicate silks to heavy canvas, and are compatible with different thread sizes and materials, including cotton, polyester, and nylon. This versatility makes them suitable for diverse sewing tasks and applications.

Tangle Prevention

One of the advantages of rotary hook shuttles is their design which minimizes the risk of thread tangling or bird nesting.

The controlled rotary motion ensures that the thread feeds smoothly, reducing the chances of thread jams or knots. This reliability is essential to maintain continuous production.

Precision and Consistency

Rotary hook shuttles contribute significantly to the precision and consistency of stitches. Their predictable rotary motion guarantees that each stitch is formed identically.

This reliability results in even seam lines and reduces the likelihood of defects, ensuring the final product meets the desired quality standards.

Low Maintenance

Rotary hook shuttles are known for their durability and minimal maintenance requirements. Their robust design reduces the need for frequent adjustments and repairs, reducing downtime and associated costs in industrial settings.

This reliability is a significant advantage for manufacturers seeking efficiency and cost-effectiveness in their sewing operations.

Variations of Rotary Hook Shuttle in Sewing Machine

Variations of rotary hook shuttles in sewing machines exist to accommodate different sewing needs and preferences.

These variations offer versatility in stitching applications and contribute to the overall performance of sewing machines.

Here are some notable variations:

Standard Rotary Hook Shuttle

This is the most common type of rotary hook shuttle found in sewing machines. It features a basic design with a single hook that rotates in a circular motion.

It is suitable for a wide range of sewing tasks and is commonly used in home sewing machines.

Large Capacity Rotary Hook Shuttle

These shuttles are designed for heavy-duty sewing applications. They have a larger bobbin capacity, which means they can hold more thread, reducing the need for frequent bobbin changes.

Large capacity rotary hook shuttles are commonly used in industrial sewing machines for sewing thick materials like leather and canvas.

Small Rotary Hook Shuttle

Conversely, small rotary hook shuttles are designed for precision sewing. They are ideal for delicate fabrics and intricate stitching patterns. The compact size of these shuttles allows for fine control over the stitching process.

Vertical Rotary Hook Shuttle

In vertical rotary hook shuttles, the hook moves in an up-and-down motion rather than a circular one. This design is often seen in embroidery machines, where precise vertical movement is crucial for creating intricate designs and patterns.

Horizontal Rotary Hook Shuttle

Horizontal rotary hook shuttles are commonly found in some industrial sewing machines. They have a horizontal orientation, making them suitable for high-speed sewing applications. These shuttles are known for their reliability and efficiency.

Self-lubricating rotary Hook Shuttle

Some modern sewing machines incorporate self-lubricating rotary hook shuttles. These shuttles have built-in lubrication systems that automatically oil the hook, reducing the need for manual maintenance and ensuring smooth operation over extended periods.

Rotary Hook Shuttle with Adjustable Timing

Sewing machines used for specialized tasks, such as quilting, may feature rotary hook shuttles with adjustable timing. This allows users to fine-tune the shuttle’s synchronization with the needle for precise stitching control.

Rotary Hook Shuttle for Multi-Needle Machines

Multi-needle sewing machines, often used in commercial embroidery and quilting, use rotary hook shuttles specifically designed to accommodate multiple needles simultaneously. These shuttles enable the creation of intricate designs and patterns with multiple thread colors.

Advantages of Rotary Hook Shuttle in Sewing Machine

The rotary hook shuttle is a critical component in many sewing machines, and it offers several advantages that contribute to the overall efficiency and performance of these machines.

This technology has been a staple in the sewing industry for many years due to its reliability and effectiveness.

Below are some of the key advantages of a rotary hook shuttle in a sewing machine:

High Stitch Quality

Rotary hook shuttles are known for producing high-quality stitches. They create even and consistent stitches, which are essential for achieving a professional and polished look in sewing projects. This is particularly important in industries like fashion and textiles, where quality is paramount.

Faster Sewing Speeds

Rotary hook shuttles allow for faster sewing speeds compared to other shuttle types, such as oscillating shuttles.

This is because the rotary hook mechanism can move swiftly and smoothly, resulting in increased productivity.

Industries with high production demands, like garment manufacturing, benefit greatly from this speed advantage.

Reduced Thread Breakage

Rotary hook shuttles are less prone to thread breakage, thanks to their smooth and continuous sewing motion.

This reduces downtime caused by thread-related issues and increases the overall efficiency of the sewing process. Fewer interruptions mean higher productivity and lower maintenance costs.

Versatility

Rotary hook shuttles are versatile and can handle a wide range of fabrics and thread types. They are suitable for sewing lightweight materials like silk and heavy-duty fabrics like denim or leather.

This versatility makes them ideal for both home sewing machines and industrial sewing machines used in various applications.

Less Noise and Vibration

Rotary hook shuttles tend to produce less noise and vibration during sewing compared to some other shuttle mechanisms.

This quieter operation is not only more pleasant for the user but also reduces the wear and tear on the sewing machine itself, potentially extending its lifespan.

Longer Stitch Lengths

Rotary hook shuttles are capable of creating longer stitch lengths, making them well-suited for tasks that require longer seams or topstitching.

This feature is valuable in upholstery work, quilting, and other applications where longer stitches are desired.

Ease of Maintenance

Rotary hook shuttles are relatively easy to maintain. They have fewer moving parts than some other shuttle types, which means there are fewer components that can wear out or break. This translates to lower maintenance costs and less downtime for servicing.

Consistent Bobbin Tension

Rotary hook shuttles help maintain consistent bobbin tension throughout the sewing process. This is essential for preventing issues like loose or uneven stitches and ensures the final product meets quality standards.

Wide Adoption

Rotary hook shuttles have been widely adopted in the sewing machine industry, which means that users can find readily available replacement parts and accessories. This accessibility simplifies repairs and maintenance, reducing downtime.

Singer Sewing Machine Shuttle Hook

The Singer Sewing Machine Shuttle Hook is a critical component of Singer sewing machines, contributing to their smooth and efficient stitching process.

It is one of the essential parts responsible for creating stitches by capturing the upper thread and interlocking it with the lower bobbin thread.

Here are some key features and information about the Singer Sewing Machine Shuttle Hook:

Design and Function

The shuttle hook in Singer sewing machines is typically a rotary hook design, known for its continuous circular motion. This design allows for precise and consistent stitch formation at various sewing speeds.

Compatibility

Singer sewing machines come in a variety of models, and while the shuttle hook design may vary slightly from model to model, the core function remains the same.

Singer’s shuttle hooks are versatile and can handle a wide range of sewing tasks, from basic stitching to more complex embroidery and decorative work.

Maintenance

To ensure smooth operation and stitch quality, it’s important to regularly clean and lubricate the shuttle hook area as per the manufacturer’s recommendations. Keeping this area free from lint and debris helps prevent thread jams and stitching issues.

Threading

Proper threading of the Singer sewing machine, including the shuttle hook area, is crucial for achieving optimal stitching results. Refer to the machine’s user manual for detailed threading instructions specific to your Singer model.

Replacement

Over time, shuttle hooks may wear out or become damaged. Fortunately, replacement shuttle hooks are often readily available from Singer or authorized dealers.

If you encounter persistent stitching problems, a damaged shuttle hook may be the culprit, and replacing it can restore your sewing machine’s performance.

Historical Significance

Singer has a rich history in sewing machine manufacturing, and its machines have been used by generations of sewers.

The design and functionality of the shuttle hook have evolved over the years, reflecting advancements in sewing technology.

Rotary Hook vs. Oscillating Hook

Sewing machines play a pivotal role in various sewing applications, from crafting and home projects to industrial manufacturing.

Two commonly used shuttle mechanisms within sewing machines are the rotary hook and oscillating hook.

Each mechanism has its unique characteristics and advantages, making it important to understand their differences to choose the right sewing machine for your specific needs.

Comparison Table: Rotary Hook vs. Oscillating Hook

| Aspect | Rotary Hook | Oscillating Hook |

| Motion | Continuous rotation in a circular motion. | Back-and-forth motion in a semi-circle. |

| Speed | Can operate at high sewing speeds. | Generally operates at lower speeds. |

| Thread Breakage | Less prone to thread breakage. | May experience more thread breakage. |

| Versatility | Suitable for a wide range of fabrics. | Better suited for lighter materials. |

| Maintenance | Requires regular cleaning and lubrication. | Simpler design, often requires less maintenance. |

| Stitch Length | Capable of creating longer stitch lengths. | Limited in creating longer stitches. |

| Application | Ideal for industrial and heavy-duty sewing. | Commonly used in home sewing machines. |

| Noise | Tends to be noisier due to higher speeds. | Generally quieter during operation. |

| Cost | Typically more expensive. | Generally more affordable. |

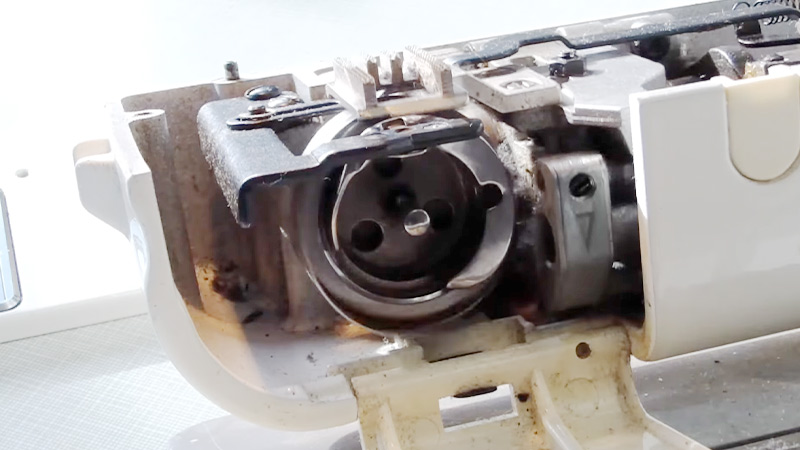

Sewing Machine Shuttle Hook Problems & Solutions

Sewing machine shuttle hook problems can be frustrating and disruptive to your sewing projects. However, many common shuttle hook issues can be resolved with some troubleshooting and basic maintenance.

Here are some common problems associated with sewing machine shuttle hooks and their potential solutions:

Thread Jamming or Snapping

Problem: The thread keeps jamming or snapping around the shuttle hook.

Solution:

- Check the threading: Ensure that you have correctly threaded the machine, following the machine’s threading diagram.

- Use good-quality thread: Poor-quality or old thread can lead to breakage. Replace the thread with a fresh, high-quality spool.

- Adjust the tension: Incorrect thread tension can cause thread issues. Adjust the upper and lower thread tensions as needed.

Skipped Stitches

Problem: The sewing machine is skipping stitches or not forming proper stitches.

Solution:

- Clean the shuttle area: Dust and lint buildup in the shuttle area can interfere with the hook’s movement. Remove the bobbin case and clean the shuttle thoroughly.

- Replace the needle: A dull or bent needle can lead to skipped stitches. Install a new, correctly sized needle and ensure it is inserted correctly.

- Check for burrs or damage: Inspect the shuttle hook for any burrs, rough spots, or damage. If you find any, gently file or sand them down.

Uneven Stitching

Problem: The stitching appears uneven or irregular.

Solution:

- Check bobbin tension: Ensure that the bobbin thread is properly tensioned. Adjust the bobbin tension if necessary.

- Adjust upper thread tension: Make sure the upper thread tension is set correctly for the fabric and thread you are using.

- Check for needle issues: A bent or damaged needle can cause uneven stitching. Replace the needle with a new one and rethread the machine.

Bobbin Thread Tangling

Problem: The bobbin thread is tangling or forming loops on the underside of the fabric.

Solution:

- Re-thread the bobbin: Remove the bobbin and bobbin case, re-thread the bobbin, and reinstall it correctly.

- Check bobbin case tension: Adjust the tension on the bobbin case to ensure it matches the upper thread tension.

- Check for bobbin issues: Ensure you are using the correct type of bobbin for your machine. Damaged or incorrectly wound bobbins can cause tangling.

Noisy Operation

Problem: The sewing machine shuttle hook area is making loud or unusual noises.

Solution:

- Clean and lubricate: Dust and lint buildup in the shuttle area can lead to noisy operation. Clean the shuttle and apply a small amount of sewing machine oil to the shuttle hook and surrounding components.

- Check for loose parts: Inspect the shuttle assembly for loose or worn parts. Tighten any loose screws or bolts and replace worn components if necessary.

Bobbin Case Doesn’t Stay in Place

Problem: The bobbin case keeps popping out of position during sewing.

Solution:

- Check bobbin case installation: Ensure that the bobbin case is correctly installed and latched into its designated position.

- Inspect for damage: If the bobbin case or its latch is damaged, replace them.

FAQS

How does a rotary hook shuttle differ from other shuttle types in sewing machines?

A rotary hook shuttle differs in its design and operation.

Can a sewing machine with a rotary hook shuttle handle heavy-duty materials like leather or canvas?

Yes, sewing machines equipped with a rotary hook shuttle are versatile and can handle heavy-duty materials like leather and canvas with ease, thanks to their robust stitching capabilities.

Do rotary hook shuttles require specific maintenance procedures compared to other shuttle types?

While basic maintenance is similar for all sewing machines, rotary hook shuttles may require less frequent cleaning and oiling due to their efficient, low-friction design.

Can a sewing machine with a rotary hook shuttle be used for embroidery and decorative stitching?

Yes, rotary hook shuttle-equipped machines are versatile and can be used for embroidery and decorative stitching, providing a wide range of creative possibilities.

To Recap

The rotary hook shuttle is not just a mechanical component within a sewing machine; it is the silent architect of precision and efficiency in the world of stitching.

Its continuous rotation ensures flawless, high-speed stitching, making it the backbone of industrial sewing processes and a reliable partner for intricate home projects.

This versatile technology accommodates various fabrics, reduces thread breakage, and offers the convenience of longer stitch lengths.

Its enduring appeal lies in its ability to transform the ordinary into the extraordinary, whether it’s a neatly tailored garment, an intricate embroidery masterpiece, or the seamless joining of fabrics.

In the craft of sewing, the rotary hook shuttle is, indeed, a cornerstone of excellence.

Leave a Reply