Sewing with cotton thread is widespread and admired for its versatility and compatibility with natural fabrics. However, it’s crucial to recognize its limitations in specific contexts.

While cotton thread is ideal for lightweight and delicate projects, it may fall short in applications demanding robust strength, stretch, or resistance to environmental factors.

This exploration sheds light on the challenges of using cotton thread, including considerations like durability, elasticity, shrinkage, color fastness, specialized uses, environmental impact, and cost.

Understanding these aspects helps crafters make informed decisions based on their sewing projects’ unique requirements, ensuring the final creations’ longevity and suitability.

What Is Wrong With Sewing With Cotton Thread?

Sewing with cotton thread is common in various sewing projects, but like any material, it comes with its challenges. Understanding these problems can help you address them effectively.

Here are some issues you might face when sewing with cotton thread:

Thread Weakness

The weakness of cotton thread can be a concern in projects with high-stress areas, such as seams in garments. Opting for a thicker or more durable cotton thread can provide additional strength.

Reinforcing critical seams, especially in areas that endure frequent movement or stress, will enhance the overall durability of your project.

Shrinkage

Cotton thread, like cotton fabric, is prone to shrinkage when exposed to water or humidity. Pre-wash the fabric and thread before sewing to avoid distortion in your finished project.

Be mindful of the care instructions for the final garment or item to ensure proper maintenance and prevent unexpected shrinkage after completion.

Cotton Thread Breakage

Breakage of cotton thread can occur for various reasons, such as using a low-quality thread or having incorrect tension settings on your sewing machine.

Choosing a high-quality cotton thread suitable for your project and ensuring proper tension adjustment can reduce the likelihood of breakage.

Regularly check your needle condition and replace it if it becomes dull, as a dull needle can contribute to thread breakage.

Color Fastness

Over time, the color of cotton thread may fade, especially with exposure to sunlight and repeated washing. Choosing high-quality, colorfast cotton threads can help mitigate this issue.

Additionally, pre-washing the fabric and thread separately can prevent color bleeding and ensure that the colors remain vibrant throughout the project’s life.

Lint Accumulation

Cotton thread produces more lint than synthetic threads, leading to potential issues like jams and decreased stitch quality.

Regularly clean and maintain your sewing machine, paying close attention to the bobbin case, tension discs, and other areas where lint may accumulate. This preventive measure will contribute to the longevity and efficiency of your sewing machine.

Limited Stretch

Cotton thread has less stretch than synthetic alternatives, which can be challenging when working with stretchy fabrics.

Adjusting your sewing machine to a slightly longer stitch length can compensate for the limited stretch.

Before starting your main project, conduct stitch tests on a scrap piece of fabric to ensure that the chosen length accommodates the fabric’s elasticity without compromising the overall integrity of the seams.

Dye Bleeding

Dye bleeding in cotton thread may occur, potentially staining the surrounding fabric when exposed to water.

Test the colorfastness of the thread before use by dampening a small section and pressing it onto a white cloth.

If there is any color transfer, pre-wash the thread separately to minimize the risk of dye bleeding during your project. Additionally, choose threads labeled as colorfast to ensure the longevity of your project’s aesthetic appeal.

Types of Cotton Thread for Sewing Machine

Cotton thread is a popular choice for sewing enthusiasts, valued for its natural fiber composition and versatility.

When using cotton thread in a sewing machine, there are several types to consider, each tailored to specific projects and preferences.

Here are some common types of cotton thread for sewing machines:

1. All-Purpose Cotton Thread

All-purpose cotton thread is the workhorse of sewing, suitable for a broad spectrum of projects. It is often made of short to medium-staple cotton fibers, balancing strength and affordability.

This thread is available in various colors and thicknesses, making it versatile for multiple fabrics and sewing techniques.

Its typical applications include garment construction, hemming, and basic repairs, making it an essential choice for everyday sewing tasks.

2. Quilting Cotton Thread

Quilting thread is specially crafted for the unique demands of quilting projects. It is typically finer than regular sewing thread, allowing for more detailed stitching and intricate quilting patterns.

The strength and durability of quilting cotton thread are crucial for securing multiple layers of fabric in quilts.

Its reduced thickness helps prevent bulk in quilted seams, contributing to the overall aesthetic appeal of quilted projects.

3. Heavy-Duty Cotton Thread

Heavy-duty cotton thread is designed for projects involving robust fabrics like denim, canvas, or leather.

This type of thread is thicker and more robust, providing the necessary tensile strength to withstand the demands of heavy materials.

Typical applications include sewing bags, upholstery, and heavyweight garments where the thread must endure significant stress and tension without compromising durability.

4. Embroidery Cotton Thread

Embroidery cotton thread is tailored for decorative stitching, adding vibrant fabric embellishments.

It possesses a smooth finish that glides effortlessly through the fabric, creating intricate and detailed designs.

This type of thread is available in many colors to bring creativity to machine embroidery and hand embroidery projects, delivering a polished and visually appealing finish to the final product.

5. Mercerized Cotton Thread

Mercerized cotton thread undergoes a treatment process called mercerization, enhancing its appearance and strength.

This process imparts a lustrous sheen to the thread, making it particularly suitable for projects where aesthetics play a crucial role.

Mercerized cotton is often chosen for decorative stitching, creating garments with a polished finish and adding a touch of elegance to various sewing applications.

6. Variegated Cotton Thread

Variegated cotton thread is characterized by multiple colors within a single strand, creating a striking visual effect when sewn.

This type of thread is famous for adding interest and dimension to quilting projects, embroidery, or any sewing where a multicolored or gradient effect is desired.

Variegated threads can turn simple stitches into visually captivating designs, making them a favorite among creative sewers.

7. Cotton Blend Thread

Cotton blend threads combine cotton with other fibers, such as polyester or rayon, to enhance specific characteristics. These blends may offer increased strength, reduced shrinkage, or improved colorfastness.

Cotton blends are often chosen for projects where a balance between the natural feel of cotton and the added benefits of synthetic fibers is desired, providing versatility in a wide range of applications.

8. Long Staple Cotton Thread

Threads made from long-staple cotton fibers are recognized for their exceptional strength and smooth texture.

Long staple cotton produces a finer, less linty thread, making it an excellent choice for precision sewing.

This type of thread is particularly suitable for projects where a neat and refined appearance is crucial, such as detailed embroidery, topstitching, or any application requiring meticulous stitching.

The extended length of the cotton fibers contributes to the overall durability and longevity of the thread.

Why Sewing Machine Thread Keeps Breaking at Needle?

Experiencing frequent thread breakage at the needle can be frustrating and disrupt the flow of your sewing project.

Several factors could contribute to this issue, and addressing them systematically can help resolve it.

Here are some common reasons why sewing machine thread keeps breaking at the needle:

Thread Quality

The quality of the thread used in sewing plays a crucial role in preventing breakage. Low-quality threads often lack the tensile strength required for seamless stitching, especially in more intricate or demanding projects.

It’s essential to invest in threads that are specifically designed for your sewing needs, considering factors such as fabric type and project requirements.

Additionally, as threads age, exposure to air and light can cause them to become brittle, leading to increased susceptibility to breakage.

Regularly assess the condition of your thread, and if in doubt, opt for a fresh spool to ensure optimal performance.

Thread Tension

Achieving the correct tension is paramount to successful sewing. Incorrect tension, whether too tight or too loose, can cause the thread to break.

Refer to your sewing machine manual for adjusting the upper thread tension. Additionally, ensure that the bobbin is correctly threaded, as an imbalance between upper and lower tensions can contribute to breakage.

Regularly check and adjust the tension settings based on the specific fabric and thread combination you are using to maintain a smooth and consistent stitch.

Needle Size and Type

Selecting the correct needle size and type is critical for preventing thread breakage. Using a too-large or too-small needle for the fabric can increase friction and strain on the thread, resulting in breakage.

Similarly, a damaged or dull needle can cause the thread to fray and snap during sewing. Regularly inspect your needles for signs of wear and replace them according to the manufacturer’s recommendations.

Choosing the appropriate needle for the fabric you are working with ensures a harmonious interaction between the needle and thread.

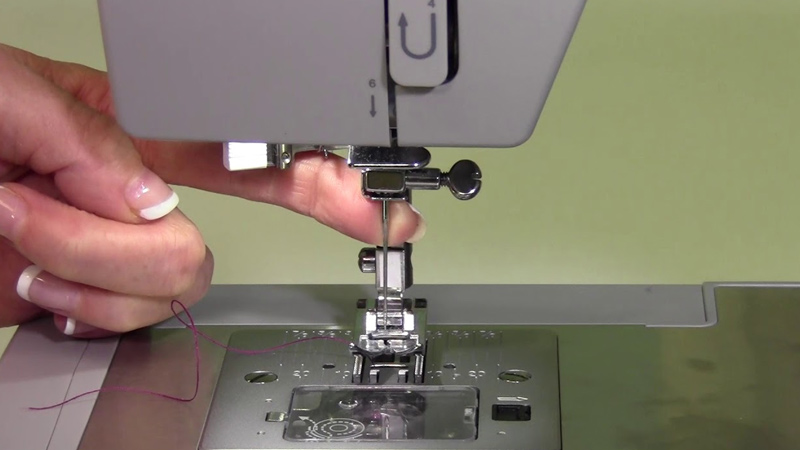

Needle Insertion

Proper needle insertion is fundamental to the smooth operation of a sewing machine. Ensure the needle is inserted with the flat side facing the back, following the guidelines in your machine’s manual.

An incorrectly inserted needle can cause the thread to break, disrupting your sewing project.

Additionally, confirm that the needle is fully seated and securely tightened in the clamp to prevent wobbling or misalignment during stitching.

Thread Path Issues

Threading errors can significantly impact your sewing machine’s tension and overall performance. Carefully inspect the upper and bobbin thread path, checking for any missteps or entanglements.

A misthreaded machine can cause irregular tension and contribute to thread breakage. Consult your sewing machine manual for detailed instructions on proper threading, and follow the recommended sequence to ensure a smooth and trouble-free sewing experience.

Taking the time to thread your machine accurately is a preventive measure that can save you from frustrating interruptions during your sewing projects.

Bobbin Issues

The bobbin, a critical component of the sewing process, can be a source of thread breakage if not handled correctly. A poorly wound bobbin may lead to uneven tension and erratic stitching.

When winding the bobbin, ensure the thread is smoothly and evenly distributed to avoid any snags or tension issues during sewing.

Proper insertion of the bobbin into the bobbin case is equally important. Check that the bobbin is securely placed, with the thread unwinding in the correct direction.

Inspect the bobbin for rough edges that might damage the thread as it passes through, and replace it if needed.

Machine Maintenance

Regular maintenance is crucial for the smooth operation of your sewing machine and to prevent thread breakage. Lint, debris, and old oil can accumulate over time and affect the machine’s performance.

Clean the bobbin case regularly, feed dogs, and the entire thread path. Additionally, follow the manufacturer’s guidelines for oiling and lubricating your machine to ensure all moving parts function smoothly.

A well-maintained machine promotes optimal thread control and reduces the likelihood of interruptions during your sewing projects.

Sewing Speed

The speed you sew at can impact the thread’s ability to handle stitching stress. Sewing too fast, especially when working with thicker fabrics or intricate patterns, can put additional strain on the thread, leading to breakage.

To prevent this issue, slow your sewing speed and allow the machine to feed the fabric smoothly and evenly.

Adjusting your pace according to the project’s complexity and the fabric’s thickness can significantly reduce the occurrence of thread breakage.

Fabric and Thread Mismatch

A mismatch between fabric weight and thread thickness can result in thread breakage. Some fabrics may be too thick or heavy for the thread you use, causing increased tension and stress during sewing.

Ensure compatibility by selecting a thread that complements the weight and characteristics of the fabric.

Adjust your needle and thread choices to achieve a harmonious balance, preventing unnecessary strain on the thread and minimizing the risk of breakage.

Bobbin Tension

The bobbin thread’s tension is a critical element in achieving balanced stitching. An improperly adjusted bobbin tension, whether too tight or loose, can disrupt the overall tension balance and lead to thread breakage at the needle.

Consult your sewing machine manual for guidelines on adjusting the bobbin tension. Make minor adjustments and test the stitches on a scrap fabric to ensure the correct tension balance.

A well-calibrated bobbin and upper thread tension contribute to smooth and consistent stitching.

FAQs

How Long Does Cotton Thread Last?

The lifespan of cotton thread varies but can last several years with proper storage. Factors such as frequency of use, project types, and storage conditions impact longevity.

Is Polyester or Cotton Thread Stronger?

A polyester thread is generally more robust than cotton. Its synthetic composition provides enhanced tensile strength, making it more breakage-resistant. Polyester is often preferred for heavy-duty sewing projects.

Is Cotton Thread Good for Sewing?

Cotton thread is excellent for sewing, especially with natural fabrics, providing a soft, breathable finish.

Does Cotton Sewing Thread Go Bad?

Yes, cotton thread can go bad over time, becoming brittle. Using fresh spools is recommended, especially if the thread shows signs of aging.

What Thread Is Best for Sewing?

The best thread depends on your project and fabric. Cotton is excellent for natural fabrics, while polyester and nylon offer strength. Choose a thread that suits your specific sewing needs.

To Recap

While cotton thread is a versatile and widely used option in sewing, it has limitations that may pose challenges in specific applications.

Its comparatively lower strength and durability make it less suitable for heavy-duty projects or those requiring significant stress resistance.

Cotton’s inherent lack of stretch and susceptibility to shrinkage may affect the overall performance in specific fabrics and conditions.

Additionally, concerns about colorfastness and environmental impact, coupled with the availability of more specialized threads, prompt a careful consideration of alternatives.

Despite these drawbacks, the cotton thread remains a valuable choice for numerous projects, particularly when matched appropriately with the fabric type and project requirements.

Leave a Reply