When it comes to sewing with knit fabrics, precision, flexibility, and durability are paramount. Enter the cover stitch machine, a specialized sewing marvel designed to achieve flawless hems on various knit materials.

This unique sewing machine stands as the unsung hero of the sewing world, quietly excelling in its ability to create professional-quality hems that not only look impeccable but also stretch harmoniously with the fabric.

With multiple threads, adjustable tension, and a differential feed mechanism, the cover stitch machine tackles the challenges posed by stretchy knits with finesse.

In this exploration, we will delve deeper into what makes the cover stitch machine the go-to choice for hemming knits, unlocking its secrets to perfect, resilient hems for all your knitwear creations.

What Kind of Sewing Machine Is Used to Hem Knits?

A sewing machine used to hem knits, particularly with a professional and stretchy finish, is commonly referred to as a “cover stitch machine.”

This specialized sewing machine is a fantastic choice for working with knit fabrics, and it’s specifically designed to create impeccable hems on such materials.

Let’s delve into the features and functions that make the cover stitch machine ideal for this purpose:

Multiple Threads

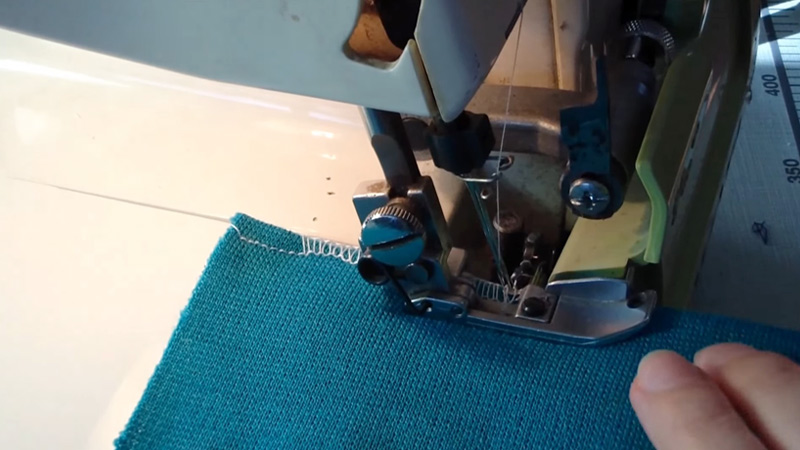

Coverstitch machines typically have two to three needles and two loopers or looper threads. This configuration allows for the creation of two or three parallel lines of stitching on the fabric’s right side while forming loops on the wrong side.

These loops ensure that the hem retains its stretch and doesn’t snap when the fabric is stretched.

Differential Feed

Most cover stitch machines come with a differential feed mechanism. This feature enables you to adjust the speed at which the fabric is fed through the machine, ensuring even stitching on fabrics with varying levels of stretch. It helps prevent puckering or stretching of the fabric during the hemming process.

Tension Control

Coverstitch machines offer adjustable tension settings, which are crucial when working with different types of knit fabrics.

Proper tension control ensures that the stitches lie flat and even on the fabric, preventing any distortion or bunching.

Stitch Width and Length Adjustment

Coverstitch machines typically allow you to adjust the width and length of the coverstitch. This flexibility is useful when creating various hem finishes, such as narrow or wide hems, or decorative cover stitching.

Free Arm

Some cover stitch machines come with a free arm, which is convenient for hemming tubular knit garments like sleeves and pant legs.

This design allows you to slide the garment onto the free arm, making it easier to sew in a continuous circle without sewing the fabric together accidentally.

Looper Threading System

Threading a cover stitch machine can be a bit more complex compared to a regular sewing machine, as it involves threading multiple threads and loopers.

However, many cover stitch machines come with color-coded threading guides and diagrams to simplify the process.

Hemming Attachments

Some cover stitch machines offer optional hemming attachments or accessories that make it easier to achieve specific hem finishes, like a blind hem or a narrow hem.

Versatility

While primarily used for hemming knit fabrics, cover stitch machines can also be utilized for other decorative stitching purposes, such as attaching elastic or creating decorative topstitching on woven fabrics.

How to Choose the Best Sewing Machine for Knit Fabric

Selecting the best sewing machine for working with knit fabrics requires careful consideration of several key factors. Knit fabrics, with their stretch and flexibility, present unique challenges that necessitate the right machine for the job.

Here’s a guide to help you choose the best sewing machine for knit fabrics:

Machine Type

- Serger/Overlocker: A serger is excellent for finishing raw edges and seaming knit fabrics. It creates secure, stretchy seams and trims excess fabric simultaneously.

- Coverstitch Machine: Ideal for hemming and adding decorative topstitching to knit fabrics, a coverstitch machine creates professional-looking, stretchy hems.

- Sewing Machine: A regular sewing machine can also work with knits when equipped with the right needle and stretch stitch options. However, sergers and cover stitch machines are better suited for specialized tasks.

Stitch Options

Look for machines that offer stretch stitches like zigzag, overlock, or lightning bolt stitches. These stitches accommodate the stretch of knit fabrics and prevent seam breakage.

Adjustable Tension

Ensure the sewing machine allows you to adjust the thread tension. Knit fabrics require different tension settings than woven fabrics, and adjustable tension is crucial for achieving balanced stitches.

Differential Feed (for Sergers)

If you opt for a serger, choose one with a differential feed mechanism. This feature prevents puckering or stretching of knit fabrics by adjusting the rate at which the fabric is fed through the machine.

Needle Options

Check if the machine can accommodate ballpoint or stretch needles. These needle types are designed specifically for knit fabrics and minimize the risk of snagging or creating runs in the fabric.

Threading Ease

Consider the ease of threading the machine, especially for sergers, which can have multiple threads and loopers. Look for color-coded threading guides or helpful threading diagrams.

Presser Foot Pressure Adjustment

Some machines allow you to adjust the presser foot pressure. This feature is beneficial for preventing knit fabrics from stretching or puckering during sewing.

Free Arm Capability

A sewing machine with a free arm feature is useful for sewing tubular knit garments, such as sleeves or pant legs, without accidentally stitching them together.

Stitch Length and Width Adjustment

Machines that allow you to adjust stitch length and width offer versatility for various knit fabric projects, including decorative topstitching.

Brand and Reviews

Research reputable sewing machine brands are known for their durability and customer support. Read user reviews and seek recommendations from experienced sewists to gauge machine performance.

Budget

Set a budget and consider the features you need most within that price range. There are sewing machines suitable for a wide range of budgets.

Test It Out

If possible, try out the machine before purchasing or read reviews from individuals who have used it for sewing knit fabrics. A test run can help you assess how well it handles the specific type of knits you intend to sew.

How to Hem Knits With a Serger?

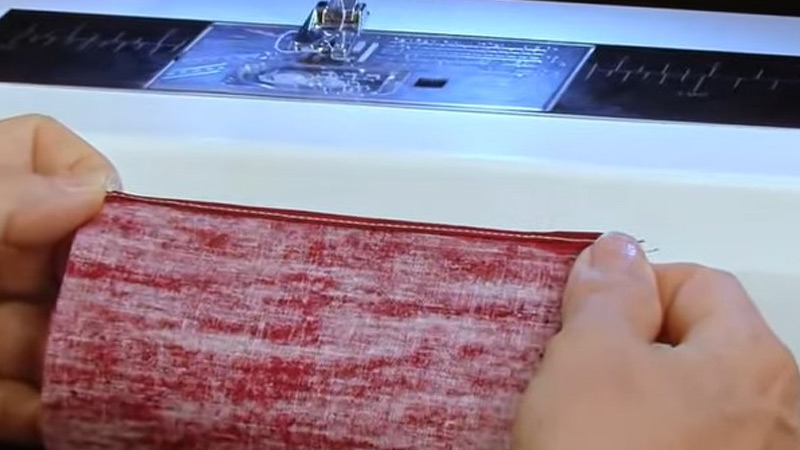

Hemming knit fabrics with a serger is a straightforward process that results in professional-looking, stretchy hems.

Follow these step-by-step instructions for hemming knits with a serger:

Materials You’ll Need:

- Knit fabric

- Serger/overlocker

- Matching thread

- Scissors or rotary cutter

- Seam gauge or ruler

- Iron and ironing board

Step 1: Set Up Your Serger

- Thread Your Serger: Make sure your serger is threaded properly with the appropriate color thread. Most sergers have four threads: two needles and two loopers. Refer to your serger’s manual for threading instructions.

- Adjust Tension: Set the thread tension according to your serger’s recommendations for the type of knit fabric you’re working with. Knit fabrics often require slightly looser tension than woven fabrics.

Step 2: Prepare Your Fabric

- Cut the Hem: Trim the edge of your knit fabric evenly to the desired hem length, leaving a little extra for the hem allowance. Use a rotary cutter or sharp scissors for a clean cut.

- Press the Hem: Fold the raw edge of the fabric up to the wrong side to create the desired hem width. Use a seam gauge or ruler to ensure an even fold. Lightly press the fold with an iron to create a crease.

Step 3: Begin Hemming

- Position the Fabric: Place your fabric under the serger foot, aligning the folded edge with the edge of the presser foot. Make sure the serger blade trims off any excess fabric while stitching.

- Start Serging: Begin serging by gently guiding the fabric through the machine. The serger will simultaneously cut the excess fabric, encase the raw edge with stitches, and create a neat, finished edge.

- Maintain Even Speed: Keep a consistent speed while guiding the fabric. Avoid pulling or stretching the fabric as it feeds through the serger to prevent distortion.

Step 4: Finish Hemming

- Overlap Stitches: When you reach the starting point, allow the serger to overlap a few stitches to secure the hem. Some sergers have the option to chain off stitches, creating a clean finish.

- Trim Threads: Trim any excess thread tails with scissors or a thread cutter.

- Press the Hem: After serging, gently press the hem with an iron set to the appropriate temperature for your fabric type. Press on the wrong side of the fabric to set the stitches and create a crisp hem.

- Optional: Topstitch (if desired): If you want to add a decorative topstitch to your hem, use a regular sewing machine with a stretch stitch or twin needle. Simply fold the hem once more to the desired width, and topstitch along the edge.

Serger Hem Types

A serger, also known as an overlocker, is a versatile machine that can create various types of hems on fabric.

The type of hem you choose depends on the fabric you’re working with and the look you want to achieve.

Here are some common serger hem types:

Basic Overlock Hem

The basic overlock hem is a straightforward and practical finishing technique. It serves the essential purpose of preventing fabric fraying by serging the fabric’s edge.

This versatile hem creates a clean and tidy appearance, making it suitable for a wide range of fabrics and garment types.

Whether you’re working with woven or knit materials, the basic overlock hem provides a reliable, finished look that ensures the longevity of your creations.

Rolled Hem

The rolled hem is a delicate and elegant finish frequently employed with lightweight and sheer fabrics such as chiffon, organza, and silk.

This hem type involves a precise folding and serging process that results in a narrow, tightly rolled edge.

The outcome is a graceful and refined appearance, making it an excellent choice for adding an air of sophistication to hems, ruffles, or edges of special occasion garments.

Flatlock Hem

The flatlock hem is a decorative hemming technique commonly used in sportswear and activewear. It creates a distinctive, flat, ladder-like stitch pattern on the fabric’s right side, with loops on the wrong side.

This unique visual element adds both style and functionality to garments, making it a popular choice for creating visually striking seams, especially on athleisure wear and swimwear.

Lettuce Edge Hem

The lettuce edge hem introduces a playful and whimsical touch to knit fabrics. Characterized by its wavy or “lettuce-like” appearance, this hem is a go-to choice for adding a decorative and dynamic finish to hems, cuffs, and edges of stretchy garments.

Achieving the lettuce edge involves adjusting the serger settings to create controlled waves along the fabric’s edge, resulting in a fun and visually engaging texture.

Wave Stitch Hem

Similar to the lettuce edge hem, the wave stitch hem is designed to create a wavy edge on fabrics. It offers an alternative decorative finish that incorporates a distinct wave pattern along the fabric’s edge.

This technique can be used to add a touch of creativity and movement to various garment elements, making it a versatile choice for those looking to experiment with unique edge treatments.

Three-Thread Narrow Hem

The three-thread narrow hem is a modification of the basic overlock hem. By utilizing only three threads instead of the standard four, it achieves a narrower and more delicate edge.

This makes it particularly suitable for lightweight and delicate fabrics, providing a neat and polished finish while reducing bulk along the hemline.

Decorative Thread Hem

Incorporating decorative or contrasting thread into your serger stitching can result in eye-catching and personalized finishes.

This technique allows you to infuse your garments with individuality and flair, enhancing the overall aesthetic.

Whether you choose to use metallic, variegated, or specialty threads, the decorative thread hem adds a unique touch to your creations.

Picot Stitch Hem

The picot stitch hem is a variation of the rolled hem that features a distinctive picot edge. This edge consists of small, decorative scallops along the fabric’s edge, adding a delicate and ornamental touch to garments.

The picot stitch hem is a wonderful choice for enhancing the visual appeal of hems, edges, and fine fabric finishes, making it a popular option for lingerie, bridalwear, and other elegant apparel.

FAQS

What stitch to use for hemming knit fabrics?

For hemming knit fabrics, it’s recommended to use a stretch stitch like a zigzag stitch, twin needle stitch, or a coverstitch.

What is the difference between a serger and a cover stitch machine for hemming knits?

A serger is primarily used for finishing raw edges and creating secure, stretchy seams, while a cover stitch machine is specifically designed for hemming knit fabrics.

A cover stitch machine creates double rows of straight stitches on the right side of the fabric and loops on the wrong side, providing both a polished look and stretch.

Can I hem knits with a regular straight stitch on a sewing machine?

Using a regular straight stitch on a sewing machine is not recommended for hemming knit fabrics.

How do I prevent my knit fabric from puckering while hemming?

To prevent puckering while hemming knit fabrics, ensure your machine’s tension settings are appropriate for the fabric.

Why is hemming stretchy fabric challenging?

Hemming stretchy fabric can be challenging because the fabric’s inherent stretchiness may cause traditional hems to pucker, break, or lose their elasticity.

To Recap

Selecting the appropriate sewing machine for hemming knit fabrics is essential for achieving professional and durable results.

The go-to choice for this task is undoubtedly the cover stitch machine, renowned for its specialized design that accommodates the unique properties of knits.

With its multiple threads, adjustable tension, and stretchy hemming capabilities, it ensures that the finished hems not only appear polished but also retain their elasticity.

While a serger can also be a valuable tool for finishing raw edges on knits, the cover stitch machine stands out as the ultimate solution for creating impeccable hems.

Investing in the right machine ensures that your knit garments will not only look great but also provide comfort and longevity.

Leave a Reply