To sew a seam with ease, place the needle with the flat side forward in your sewing machine and use the blunt end of the needle to feed fabric into the machine.

When you’re ready to start stitching, position your fabric where you want it and make sure that both pieces are correctly aligned before Beginning Sewing. Keep your stitches close together so there’s less chance for thread snagging or fraying on finished products.

Use a light hand when pressing seams allowances closed – too much pressure can cause them to pucker or pull apart over time. Follow these simple tips and enjoy an easy-to-sew project every time.

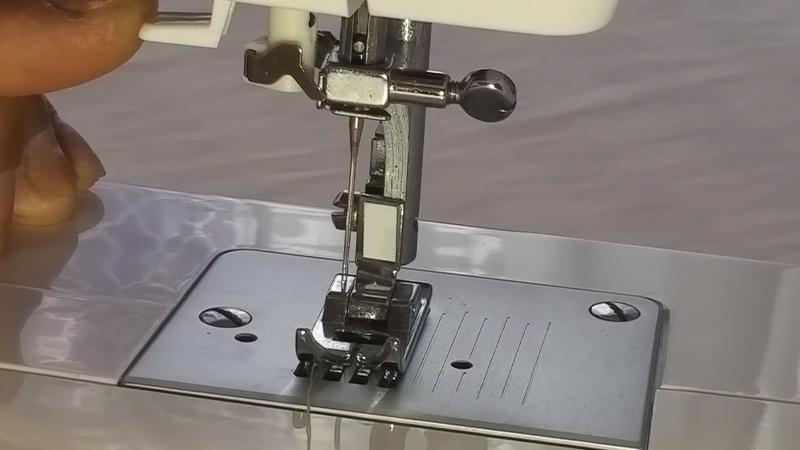

What Side Of Sewing Machine Needle Faces Outward?

Place the needle with its flat side forward in the sewing machine. Use the blunt end of the sewing machine needle to feed fabric into the machine. Sew according to your chosen stitch type and speed, making sure that you keep tension on both threads throughout your stitching process When finished, remove your fabric project from the machine and admire your handiwork.

Which way does flat side of needle go in sewing machine?

The flat side of the needle goes towards the back when you’re sewing with a regular machine, depending on which type of sewing it is. For some specialty needles with completely round shanks, the flat side may go in any direction.

When you are using a special needle for a particular project, like hems or lace fabrics, make sure to follow the instructions that come with it so your stitches will look their best. Don’t worry if you get confused; there’s plenty of information available online and from your local Sewing Machine Center to help guide you through this process step-by-step.

Keep all your needles organized in one place by storing them in a safe and easy-to-reach location – like near your machine.

Which is the front of a sewing machine needle?

The front of a sewing machine needle is typically round on the upper part and flat on the back. This is the part of the needle that goes into a machine, and it only comes out one way – towards the fabric you’re working with.

On most machines, this rounded end faces forward when inserted into the stitch holder – so it’s in front of your work. If you need to change colors while stitching, be sure to turn your seam ripper around so that its blade is facing away from your project – otherwise, particles might get left behind on your fabric (and then they’ll show up as white lines or dots when you try to finish”).

And finally: although needles come in all sorts of shapes and sizes, there are basically just three types- straight needles for fabrics with satin finishes; zigzag needles for textured fabrics; and embroidery/tapestry needles that have both ends twisted like antennas.

Which direction is the long groove on the needle placed in the machine?

When you’re Sewing With a Machine, it’s important to be aware of the direction that the long groove on the needle is placed in. This indent near the eye of the needle will make it easier for your stitches to line up properly and give you a better result.

It can be tough to see this groove if you’re not looking for it, but try focusing on where it’s located on your machine and you’ll be good to go. Be mindful when sewing with machines – even beginner sewers should take note of these directions so their projects turn out correctly.

Now go forth and conquer sewers everywhere with correct stitching techniques :).

Which way does the needle go in a Singer Featherweight?

When inserting a needle, make sure the needle’s flat side is facing the left. Thread the needle always from the right to the left on a Singer Featherweight 221, 222 and 301.

After winding the bobbin, it will need to be placed in a position so that the thread is going counter-clockwise. If you’re having trouble with your machine or have any other questions about it, consult your local retailer for help.

Keep these tips in mind when using your Singer Featherweight 221, 222 or 301–they’ll make sewing much easier.

Why is my needle hitting the metal plate?

If your machine is still not working, you might need to check the installation of the needle. Another issue could be a loose clamp screw on your sewing machine that’s preventing the needle from sticking properly into the fabric feeder.

If none of these solutions work, it may be time for a new needle or to have the entire sewing machine serviced. Make sure that when installing your new needles, they are inserted in such a way as to face towards the back of your sewing machine – this will help avoid any problems with them hitting metal plates inside.

Finally, always keep an eye on how smooth and steady your hand is while stitching- if something feels off it’s probably best to get professional help before continuing.

How do you tell the difference between sewing machine needles?

To determine the size of a sewing machine needle, first measure the circumference of the fabric you will be using it on. Then look up the corresponding metric needle size in your sewing machine’s manual or online resource.

Compare this number to what is printed on the needles you have and choose the correct one. If there are multiple sizes available, select according to gauge (thickness) – thinner needles for delicate fabrics and thicker ones for tougher materials like denim jeans..

Finally, place each needle into its respective eyelet on your Singer Sewing Machine before starting to sew.

Are sewing machine needles all the same?

Sewing machine needles come in a variety of shapes and sizes, but they all have one thing in common-they’re meant to pierce the fabric of your sewing project.

The different types of needles are designed for specific purposes such as straight stitches, zigzag stitches, or overcast stitches. It’s important to choose the correct type of needle for the task at hand before starting your sewing project.

If you ever switch between different types of needles on a regular basis, it can wear down your machine’s threading mechanism and cause jams and other complications during sewing projects. Always keep a supply of replacement needles on hand in case an old or worn-out needle becomes unusable while you’re working on a project–it could make all the difference.

Frequently Asked Questions

Do old sewing machines use the same needles?

It is not top quality – that’s no secret. Singer domestic sewing machine needles of type 15×1 (a.k.a. HAx1 or 130/705H) are actually different from needles of the same type made by other manufacturers, both needles of top quality and needles of “great value”

Why is the long groove on a sewing machine needle significant?

The groove on a sewing machine needle is significant because it helps keep the thread tight as it moves through the fabric.

What is the hole in a sewing needle called?

Open the thread end of a sewing needle. Look for a hole near the top, which is called an eye. Clean it if there is any dirt or dust on it.

Why is my sewing machine not stitching?

Check the needle installation and type of thread used, as well as the project’s specific stitch requirements. If everything looks normal, try again later.

To Recap

The side of the sewing machine needle that faces outward is used to sew through fabrics with a straight stitch.

Leave a Reply