Encountering bubbles in a sewing machine can be perplexing and disruptive to the smooth flow of a sewing project.

Understanding the reasons behind why bubbles form in a sewing machine is crucial for maintaining the integrity of the stitches and achieving professional-looking results.

Whether you are a seasoned seamstress or a novice, troubleshooting and addressing this issue promptly can make a significant difference in the quality of your sewing.

In this exploration, we will delve into is aluminum craft wire good for wire-wrapped jewelry, providing insights into common problems and effective solutions to ensure a seamless and frustration-free sewing experience.

7 Reasons Why Are Bubbles Coming In Sewing Machines?

Encountering bubbles in your sewing machine can be frustrating. Understanding the reasons behind sewing bubbles or fabric bubbling is crucial for troubleshooting. Here are seven common causes:

1. Tension Issues

Incorrect thread tension can lead to sew bubbles. Ensure proper tension adjustment for both the upper and lower threads to prevent uneven stitching that may result in bubbles on the fabric.

2. Needle Problems

A damaged or dull needle can cause fabric bubbling. Regularly replace needles to maintain their sharpness and prevent issues like skipped stitches, which contribute to uneven fabric.

3. Thread Quality

Low-quality or old thread can cause bubbling on fabric. Choose high-quality threads suitable for your fabric type, and store them properly to prevent deterioration.

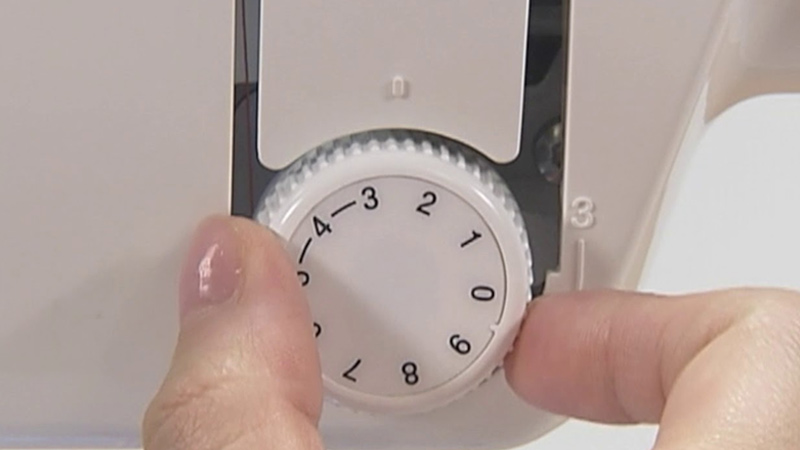

4. Bobbin Tension

Incorrect bobbin tension is a common culprit. Ensure proper winding and installation of the bobbin, adjusting tension as needed to prevent bubbles in the sewn fabric.

5. Uneven Fabric Feed

Uneven fabric feed can lead to fabric bubbling. Check the feed dogs and presser feet to ensure smooth and consistent fabric movement during sewing.

6. Machine Maintenance

Lack of regular maintenance can contribute to sew bubbles. Keep your sewing machine clean, lubricated, and well-adjusted to ensure optimal performance and prevent stitching irregularities.

7. Fabric Handling

Incorrect handling of the fabric can result in bubbles. Ensure the fabric is positioned and guided smoothly through the machine, avoiding abrupt movements that may cause uneven stitching.

By addressing these common issues, you can minimize or eliminate the occurrence of bubbles in your sewing projects, achieving smooth and professional-looking results.

How To Fix Stitching Coming Undone?

Experiencing issues with stitching coming undone can be frustrating, but several solutions can help rectify the problem. Here are five ways to address issues such as stitches bubbling or a sewing machine threaded but not stitching:

Check Thread Tension

Incorrect thread tension is a common cause of stitches coming undone. Ensure that both the upper and lower thread tensions are correctly adjusted for your fabric type. Experiment with small test samples to find the optimal tension settings.

Inspect Needle Quality and Placement

A dull or bent needle can contribute to stitching issues. Replace the needle regularly and make sure it is correctly inserted with the flat side facing the back. Using the right needle type for your fabric can also prevent problems like skipped stitches.

Examine Bobbin and Bobbin Case

Issues with the bobbin, such as improper winding or tension, can result in undone stitches. Check that the bobbin is correctly threaded and securely placed in the bobbin case. Adjust the bobbin tension if needed.

Verify Thread Quality

Low-quality or old thread can cause problems like stitches bubbling. Use high-quality thread suitable for your fabric and ensure it is threaded correctly through the machine, passing through all guides and tension discs.

Review Sewing Machine Settings

Incorrect sewing machine settings, such as stitch length or width, can impact the integrity of your stitches. Double-check that your machine is set to the appropriate settings for your sewing project, and make any necessary adjustments to avoid sewing machine threaded but not stitching issues.

By systematically addressing these factors, you can troubleshoot and resolve the problem of stitches coming undone, ensuring a more consistent and reliable sewing experience.

Leave a Reply