Sewing machines, marvels of mechanical ingenuity, have evolved over centuries to become indispensable tools in our lives.

At the heart of these remarkable machines lies a seemingly modest component – the bottom spool, or bobbin.

While easily overlooked, the bottom spool plays a pivotal role in the art and craft of sewing.

Its presence beneath the fabric serves a crucial purpose, intricately intertwined with the delicate dance of thread and needle.

In this exploration, we delve into the reasons why sewing machines have bottom spools, unveiling the secrets behind their role in maintaining tension, forming stitches, and ultimately transforming fabrics into functional and artistic creations.

What Are Bottom Spools on a Sewing Machine?

Bottom spools, also known as bobbins, are small, cylindrical components within a sewing machine that hold the lower thread.

Positioned beneath the fabric, these spools play a pivotal role in the stitching process.

As the upper thread from the primary spool above the machine passes through the needle, it interlocks with the thread from the bobbin below, creating a secure and durable stitch.

Bottom spools are crucial for maintaining proper thread tension, ensuring consistent and even stitches.

They also allow for the use of different thread colors and materials in the bobbin, enabling versatility in sewing projects.

Bottom spools are a fundamental part of sewing machines, contributing to their functionality, precision, and adaptability.

Why Do Sewing Machines Have Bottom Spools?

Sewing machines have bottom spools, also known as bobbins, for several important reasons.

These tiny spools play a critical role in the stitching process and contribute to the overall functionality and efficiency of sewing machines.

Here are the primary reasons why sewing machines have bottom spools:

1. Thread Tension Control

One of the most crucial functions of the bottom spool is to help control the tension of the thread.

The top thread (the one wound on the sewing machine’s main spool) and the bottom thread need to be balanced in tension for a proper stitch formation.

The bobbin tension can be adjusted to match the tension of the top thread, ensuring that the stitches are even and consistent.

2. Lockstitch Formation

Most sewing machines use a lockstitch mechanism to join fabric layers together securely.

In a lockstitch, the top thread and the bottom thread interlock between the fabric layers, creating a strong and durable seam.

The bottom spool supplies the lower thread required for this interlocking process.

3. Thread Storage

Bobbins provide a convenient way to store a significant amount of thread in a compact space.

By winding thread onto a bobbin, you can use much longer thread lengths without needing to constantly change the bobbin.

This is especially useful for projects that require a lot of stitching, as it reduces the need for frequent bobbin replacement.

4. Thread Color and Material Variation

Sewing often requires the use of different thread colors and materials to match the fabric or achieve specific decorative effects.

Having a separate bottom spool allows you to use a different thread color or material in the bobbin than what is on the top spool.

This versatility is essential for various sewing techniques, such as decorative stitching and embroidery.

5. Sewing Machine Mechanics

The design of sewing machines is based on a top thread (needle thread) and a bottom thread (bobbin thread) coming together to form a stitch. This design has been refined over centuries to optimize the sewing process.

It allows for precise control of the stitch formation and ensures that the threads meet at the right moment, resulting in a secure and accurate stitch.

6. Thread Thickness and Material Compatibility

Different types of threads have varying thicknesses and properties. By having a separate bobbin, sewers can choose a thread specifically suited to the bottom layer of fabric.

This adaptability ensures that the stitch remains consistent, even when working with different fabric types or thicknesses.

7. Reduced Thread Waste

Sewing machines with bottom spools help minimize thread waste. When you run out of thread on the top spool, you can often continue using the remaining thread on the bobbin before needing to replace it.

This feature reduces the amount of thread that would otherwise be discarded.

8. Preventing Thread Jamming

The bottom spool is situated in the bobbin case, which is designed to prevent thread jams and snarls during sewing.

The bobbin case keeps the bobbin thread in place and feeds it smoothly to prevent tangling, ensuring uninterrupted stitching.

9. Efficient Sewing

Bottom spools contribute to the efficiency of sewing machines by reducing the need for frequent thread changes.

This is especially important in industrial sewing settings, where time is of the essence and frequent bobbin replacements would slow down production.

10. Embroidery and Decorative Stitches

In embroidery and decorative stitching, the bobbin thread can be different from the top thread to create unique patterns and textures.

Having a separate bottom spool allows for creative freedom when designing intricate designs and embellishments.

How to Use Bottom Spools Correctly?

Using bottom spools, or bobbins, correctly is essential for achieving high-quality stitching on a sewing machine.

Here are the steps to use bottom spools correctly:

Select the Right Bobbin

Ensure that you choose the correct bobbin type for your sewing machine. Bobbins come in various sizes and materials, so refer to your sewing machine’s manual to identify the appropriate bobbin for your machine.

Wind the Bobbin

Wind the thread onto the bobbin. To do this, follow these steps:

- Place the empty bobbin on the bobbin winder spindle.

- Thread the thread through the bobbin’s tension disc, if your machine has one.

- Start the sewing machine and engage the bobbin winding mechanism.

- The machine will wind the thread onto the bobbin evenly. Stop when the bobbin is sufficiently filled, leaving a small tail of thread.

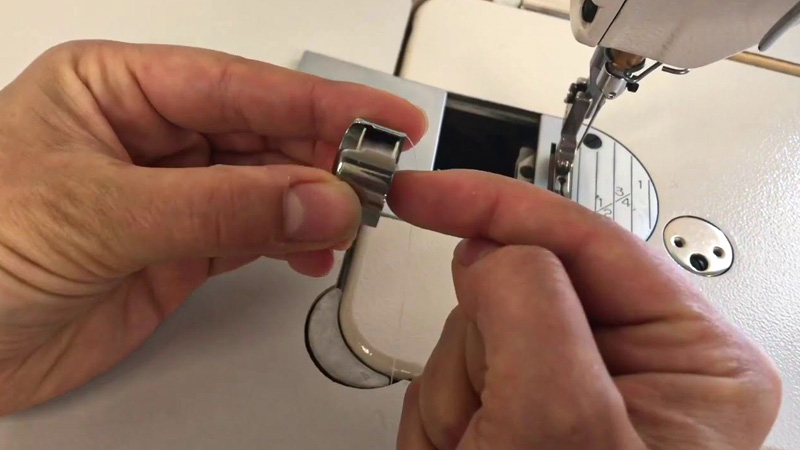

Insert the Bobbin

Open the bobbin case cover and insert the wound bobbin into the bobbin case. Follow the arrows or guides inside the bobbin case to ensure the thread is correctly threaded.

Thread the Bobbin Case

Pull the thread through the bobbin case’s thread guides or tension spring, as specified in your sewing machine’s manual.

Place the Bobbin Case

Carefully place the bobbin case into the bobbin housing. Make sure it is securely seated and that the thread tail is accessible.

Thread the Upper Thread

Thread the upper thread from the main spool through the machine’s threading path, following the machine’s threading guide.

Ensure that the presser foot is raised while threading to allow for proper tension control.

Bring Up the Bobbin Thread

Hold the end of the upper thread and manually turn the handwheel toward you to lower the needle and then raise it back up.

This will catch the bobbin thread and bring it up through the needle plate.

Hold Both Threads

Once both the upper and bobbin threads are up, gently pull them toward the back of the machine, leaving a few inches of thread tails for both threads.

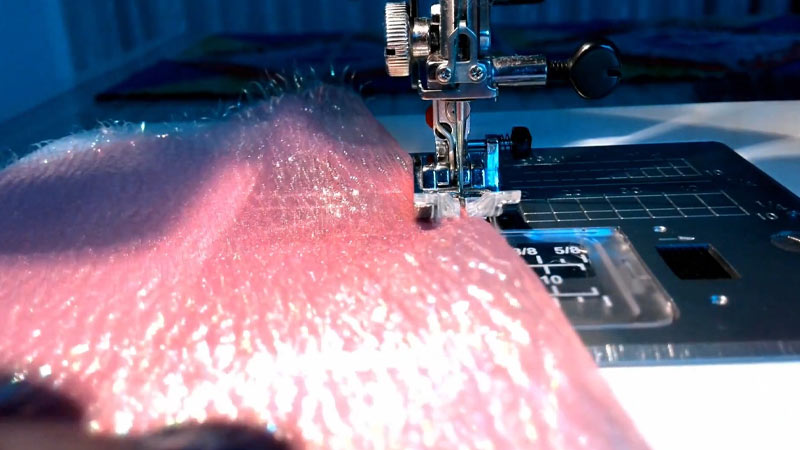

Begin Sewing

Lower the presser foot, align your fabric under the needle, and start sewing.

The machine will automatically interlock the upper and bobbin threads to form stitches as you sew.

Monitor Thread Tension

Throughout your sewing project, pay attention to the tension of both the upper and bobbin threads. If necessary, adjust the bobbin tension using the tension screw on the bobbin case

What Are Some Common Problems Related to Bottom Spools?

Common problems related to bottom spools (bobbins) on a sewing machine can disrupt the stitching process and lead to subpar results.

Here are some of the most frequent issues:

Thread Tension Problems

Incorrect bobbin tension can result in loose or tight stitches. If the bobbin tension is too loose, you may see loops on the top of the fabric; if it’s too tight, you’ll see loops on the bottom.

Adjust the bobbin tension as needed to achieve balanced stitching.

Bobbin Thread Jamming

If the bobbin thread gets tangled or jammed in the bobbin case, it can cause the machine to stop or produce irregular stitches.

This can happen due to improper threading, using low-quality thread, or lint buildup in the bobbin area.

Regularly clean the bobbin area and ensure the bobbin is inserted correctly.

Thread Snapping

A common issue is the bobbin thread breaking during sewing. This can occur if the bobbin thread is not wound evenly on the bobbin, if there are sharp edges on the bobbin, or if the thread is too old and brittle.

Use good-quality thread, wind bobbins evenly, and inspect bobbins for any defects.

Bobbin Running Out of Thread

If you run out of bobbin thread in the middle of a seam, it can be frustrating and lead to uneven stitches.

Keep an eye on the bobbin thread supply, and replace it with a new one when it’s running low to avoid interruptions.

Bobbin Thread Popping Out

Sometimes, the bobbin thread may pop out of its tension spring or guides, causing stitching problems.

Ensure the bobbin thread is correctly threaded through all the guides and tension discs in the bobbin case.

Thread Nesting (Bird’s Nesting)

When the upper and lower threads become tangled under the fabric, it creates a mess known as thread nesting or bird’s nesting.

This can occur if the machine is not threaded properly, the tension is imbalanced, or if the fabric isn’t held securely. Rethread the machine and ensure proper fabric handling.

Bobbin Type Mismatch

Using the wrong type or size of bobbin can cause issues. Always use the recommended bobbin type and size for your sewing machine model as specified in the manual.

What Are the Solutions to Bottom Spool Problems?

Solutions to common bottom spool problems on a sewing machine can help you troubleshoot and resolve issues that may arise during sewing.

Here are solutions to some of the common problems related to bottom spools:

Thread Tension Problems

Adjust the bobbin tension. If the stitches are too loose, tighten the bobbin tension screw (clockwise); if they are too tight, loosen it.

Refer to your sewing machine’s manual for specific instructions on adjusting bobbin tension.

Bobbin Thread Jamming

Remove the bobbin and bobbin case and clean any lint or debris from the bobbin area. Ensure the bobbin is correctly threaded and placed in the bobbin case.

Use high-quality thread to reduce the risk of thread jamming. Check for any burrs or rough edges on the bobbin that might be causing thread snags.

Thread Snapping

Ensure the bobbin thread is wound evenly on the bobbin. Use a good-quality thread suitable for your sewing project.

Replace old or brittle bobbin thread. Check for any rough spots on the bobbin case that might be damaging the thread.

Bobbin Running Out of Thread

Regularly check the bobbin thread supply and replace the bobbin when it’s running low to avoid interruptions.

Bobbin Thread Popping Out

Double-check that the bobbin thread is correctly threaded through all the guides and tension discs in the bobbin case. Ensure it’s properly seated.

Thread Nesting (Bird’s Nesting)

Rethread the upper and bobbin threads following the machine’s threading path carefully.

Ensure the presser foot is down when sewing to engage the tension discs properly.

Hold the thread tails when starting a seam to prevent them from getting pulled under the fabric.

Bobbin Type Mismatch

Always use the recommended bobbin type and size for your sewing machine model as specified in the manual.

FAQs

Why do sewing machines have bottom spools?

Sewing machines have bottom spools, or bobbins, to create a lockstitch by interlocking the upper and lower threads, ensuring secure and durable seams.

What role does the bobbin play in sewing?

The bobbin controls the lower thread’s tension, contributes to even stitching, and allows for various thread colors and materials.

Can I use any bobbin with my sewing machine?

It’s crucial to use the specific bobbin recommended by your sewing machine’s manufacturer to ensure proper fit and function.

How do I prevent bobbin-related issues like thread jamming?

Regularly clean the bobbin area, wind bobbins evenly, and use high-quality thread to minimize problems like thread jams.

Do I need to adjust the bobbin tension?

In some cases, adjusting bobbin tension may be necessary to achieve balanced stitching; consult your sewing machine’s manual for guidance on tension adjustments.

To Wrap Up

The unassuming bottom spool, or bobbin, is a linchpin in the world of sewing machines.

Its presence ensures precision, consistency, and versatility in stitching, enabling the creation of everything from clothing to intricate embroidery.

Through its role in tension control, lockstitch formation, and thread storage, it contributes significantly to the success of sewing projects.

The marriage of the upper and lower threads, facilitated by the bottom spool, results in the artistry of sewing, transforming fabric into functional, fashionable, and imaginative designs.

Thus, the humble bobbin reminds us that even the smallest components can have a profound impact on the creative and practical aspects of sewing.

Leave a Reply