A well-done double-threaded seam will keep your clothing together and make it easier to remove fabric that you don’t want. The process of stitching two layers of fabric together creates a sturdy seam, which is less likely to tear or fray in the future.

Being able to see any mistakes made while sewing is key for avoiding run-ins with unwanted fabric later on down the line. If a thread breaks, there’s usually little risk of having a hole develop in your garment as opposed to letting the entire piece fall apart due to an unnoticed mistake.

Finally, if one thread does happen to break during stitching – it’s much less likely that this will result in an unsightly hole than if you attempted single-threading and had trouble getting the stitches tight enough.

Why Do Sewing Machines Have Two Threads?

Make sure the thread is doubled before stitching. It’s easier to see any mistakes if you take your time and stitch neatly. If a mistake is made, it’s less likely that the fabric will tear or there will be holes in your garment as a result of this mishap.

When taking apart an item that has been sewn together properly, it will be much simpler to do so with double-threaded stitching intact rather than having to try and piece things back together without it. Keep your stitches close together for a stronger seam – this will also help reduce the amount of fabric needed when sewing something back together again later on down the track.

Do you need upper and lower thread to sew?

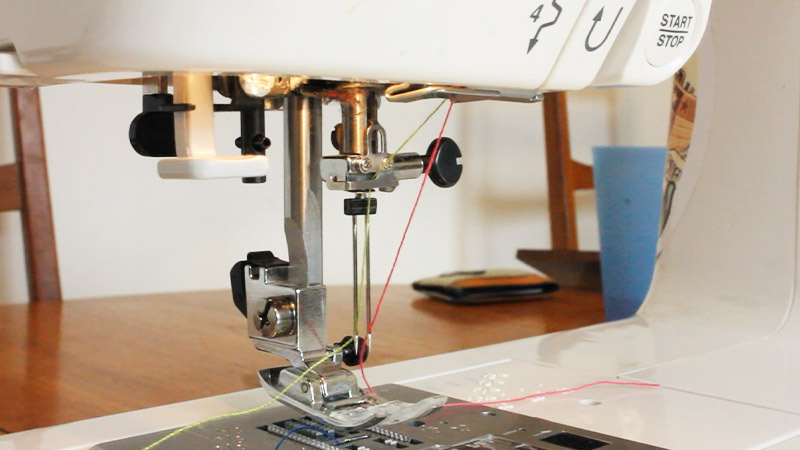

Before you start sewing, make sure that your machine has the correct thread and bobbins. The upper thread is wound on a spool by hand or with a motorized winding device in some models of machines.

To sew correctly, use both threads to create stitches in different areas of the fabric – this will help prevent frays and uneven seams. When you’re finished stitching, unwind the lower thread from the bobbin using either an automatic gearbox or by hand and store it separately until next time you sew.

Always be mindful when changing threads so as not to lose any precious snippets.

Why are two threads coming from bobbin?

When your bobbin tension is too loose, extra thread may unwind from the bobbin, which causes a buildup of thread underneath the needle plate. To tighten the Bobbin tension by turning the screw on the Bobbin Case a quarter turn clockwise; The top thread isn’t threaded correctly when you have this problem- try fixing it with a new spindle or adjusting your sewing machine’s stitch length; You can also fix this issue by cleaning out under your needle plate and around your bobbin with an emery board or diamond sharpener;5 Finally, if all else fails, you might need to replace your sewing machine.

Why are there two spool holders on a sewing machine?

When you are threading the machine, it is important to keep the spool in the correct holder. There are two holders: a horizontal one for front-to-back sewing and a vertical one for side-to-side sewing.

The vertical holder is on the right side of your machine when looking from behind it and the horizontal holder is on the left side when looking at your machine from behind it (see diagram). You use whichever holder has more thread coming out of it so that you don’t have to rewind too much thread unnecessarily (front to back vs side to side).

Pay attention to which type of stitching you want to do and adjust your tension accordingly.

What does the lower thread do?

The lower thread feeds from the bobbin and provides a loop for the upper thread to catch onto. Likewise, the bobbin thread loops into the upper thread, completing the stitch.

This is how stitches are created on your sewing machine – with two threads working together. Keep these important details in mind when choosing which type of needle to use and you’ll be stitching like a pro in no time.

For more help understanding how your sewing machine works, consult your manual or ask an expert at a local Sewing Workshop.

Can I sew without a bottom bobbin?

To sew without a bottom bobbin, you will need to use your chain stitch machine and an appropriate type of bobbin. Make sure that the bobbin is compatible with your machine before beginning sewing by consulting your manual or online resources.

Always keep a spare in case of an emergency; it can save time and frustration on important projects. If you have any questions about how to thread the machine or what types of stitches work best with a particular type of bobbin, don’t hesitate to ask your local Sewing Machine Expert for help.

Bottom bobbins are not necessary for every project – consult your manual or online resources to see which specialty stitches might be easier without one.

Why does my sewing machine thread bunch up underneath?

If you’re having trouble with your sewing machine thread bunching up, it may be because of the tension that’s been set on the upper thread. You can loosen your bobbin tension by adjusting the screw on top of your machine, but if this still doesn’t work try loosening both threads simultaneously- it may even require a special wrench or nut to do so.

Finally, if all else fails and you’ve tried everything and are still getting tangled thread underneath your fabric- give up for now and take it in for servicing- there could be something wrong with your machine that needs attention. Thread breaking is one common issue caused by too-tight bobbins or tensions when sewing; make sure not to overwork your machine by playing things safe and consulting manufacturer guidelines first.

Before trying any of these tips, always check to see if there might actually be something wrong mechanically with the sewing machine itself- otherwise, you’ll end up spending more money than necessary on repairs down the road.

What is bird nesting in sewing?

Birds nesting in sewing is caused by a number of factors, including incorrect threading or tension. If you notice your stitches are becoming uneven or broken, it’s time to take action.

There are several ways to fix bird nesting in sewing without having to replace the machine; try adjusting the needle position or changing out the top thread for a different type. Checking your machine’s tension and making sure all threads are properly threaded can go a long way in avoiding this problem altogether.

Always be mindful when sewing – keep an eye on those pesky birds and don’t let them bring havoc into your stitching world.

Frequently Asked Questions

Why is the back of my sewing messy?

If the machine isn’t threaded correctly, tighten the tension of both threads until it is balanced.

Can you use a sewing machine without a spool pin?

If your machine does not have a spool cap, it is possible to purchase one online or at a sewing store.

What do you call the upper thread holder of the sewing machine?

You may call this the “spool pin.”

What is the difference between a bobbin and a spool?

The difference between a bobbin and a spool is that the spool thread comes from the top of the machine while the bobbin thread goes through the lower thread guide.

Does top thread go under the presser foot?

threads should be pulled fairly easily – if they are not, thread the needle underneath and back up.

To Recap

One of the main reasons sewing machines have two threads is so that they can create a seam with either thread. If one thread breaks, the machine will still be able to sew using the other thread – this is called ‘thread-over-the-edge’ stitching.

Leave a Reply