Regularly cleaning lint from your sewing machine is an often-overlooked yet crucial practice for every seamstress, tailor, or sewing enthusiast.

Lint, those tiny fabric fibers and thread remnants left behind during sewing, can accumulate in various nooks and crannies of your machine, silently wreaking havoc.

This seemingly harmless byproduct can lead to thread jams, diminished stitch quality, premature wear and tear on machine components, fire hazards, and even costly repairs.

In this age of disposable consumer goods, maintaining your sewing machine through proper lint removal not only ensures optimal performance but also extends its lifespan, ultimately saving you time, money, and frustration in the long run.

What Is Lint in Sewing Machine?

In the context of a sewing machine, “lint” refers to the tiny fibers, threads, and fabric remnants that accumulate during the sewing process.

These particles can get caught in various parts of the machine, such as the bobbin area, feed dogs, and tension disks.

Lint buildup can negatively affect the sewing machine’s performance and longevity. It can cause issues like thread jams, uneven stitching, and even damage to internal components if left unaddressed.

To prevent lint-related problems, it’s essential to regularly clean and maintain your sewing machine. This involves removing lint and debris from the machine’s nooks and crannies using tools like a small brush or a lint roller.

Additionally, oiling the machine as per the manufacturer’s recommendations can help reduce friction and further protect it from wear and tear caused by lint accumulation.

Proper maintenance ensures your sewing machine operates smoothly and produces high-quality stitches.

Why Is It Important to Clean Lint From Sewing?

Cleaning lint from your sewing machine is an essential aspect of proper sewing machine maintenance. Lint is a common byproduct of sewing, and it accumulates in various parts of the machine over time.

Failing to regularly clean lint from your sewing machine can lead to several issues that can affect your sewing experience and the overall performance of your machine.

Here are some reasons why it is important to clean lint from your sewing machine:

Prevent Thread Jams

Lint can get caught in the tension disks, bobbin case, and other critical parts of the machine, leading to thread jams.

When lint accumulates in these areas, it can disrupt the smooth flow of the thread and cause your machine to seize up. This not only interrupts your sewing project but can also damage your machine if left unattended.

Maintain Stitch Quality

Lint buildup can affect the quality of your stitches. It can cause skipped stitches, uneven tension, and other irregularities in your sewing.

Regularly cleaning your machine ensures that your stitches remain consistent and your projects come out looking neat and professional.

Extend Machine Lifespan

Sewing machines are a significant investment, and proper maintenance is key to ensuring their longevity.

Lint can contribute to wear and tear on various components, including the motor and the mechanical parts of the machine. Regular cleaning can help extend the lifespan of your sewing machine, saving you money on repairs and replacements.

Reduce Fire Hazard

Lint is highly flammable, and when it accumulates in your sewing machine, it can become a fire hazard.

Sewing at high speeds generates heat, and if there’s an excess of lint near the machine’s motor or electrical components, it can catch fire.

Cleaning the lint not only helps keep your machine safe but also prevents a potential fire hazard.

Prevent Needle Damage

Lint can get wrapped around the needle and cause it to become dull or bent. A damaged needle can lead to problems like uneven stitching, fabric snags, or even fabric damage.

Regular cleaning ensures that your needles stay in good condition, which is vital for precise and effortless sewing.

Avoid Expensive Repairs

Neglecting to clean lint from your sewing machine can result in costly repairs. Lint buildup can affect the overall functionality of your machine, and the accumulated damage may not be apparent until it’s too late.

Routine cleaning is a simple preventive measure that can save you from expensive repair bills down the line.

Sew More Efficiently

A clean sewing machine operates more efficiently. Lints can slow down the machine’s moving parts and impede its performance.

By keeping your machine clean, you’ll be able to sew more efficiently and complete your projects with less frustration.

How to Clean Feed Dogs Sewing Machine?

Cleaning the feed dogs of a sewing machine is a fundamental maintenance task that can greatly improve your sewing experience.

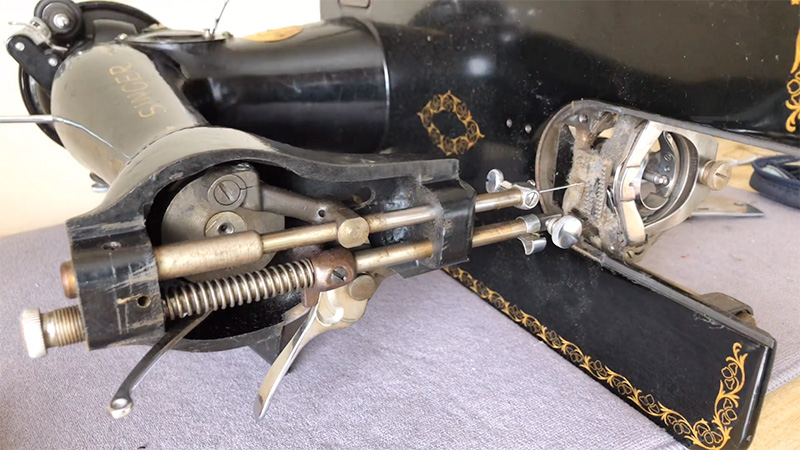

Feed dogs are the small, metal, tooth-like mechanisms that move the fabric forward while you sew. Over time, they can accumulate lint, dust, and fabric debris, causing them to lose grip and making it difficult to feed the fabric smoothly.

Here’s how to clean the feed dogs of a sewing machine:

Materials you’ll need:

- Screwdriver

- Lint Brush or Tweezers

- Soft Cloth or Q-tip

- Sewing Machine Oil

Steps:

Safety First

Before starting any maintenance on your sewing machine, prioritize safety. Ensure that your sewing machine is completely unplugged to prevent accidental activation during cleaning.

Additionally, raise the needle to its highest position using the handwheel to make it easier to access the feed dog area.

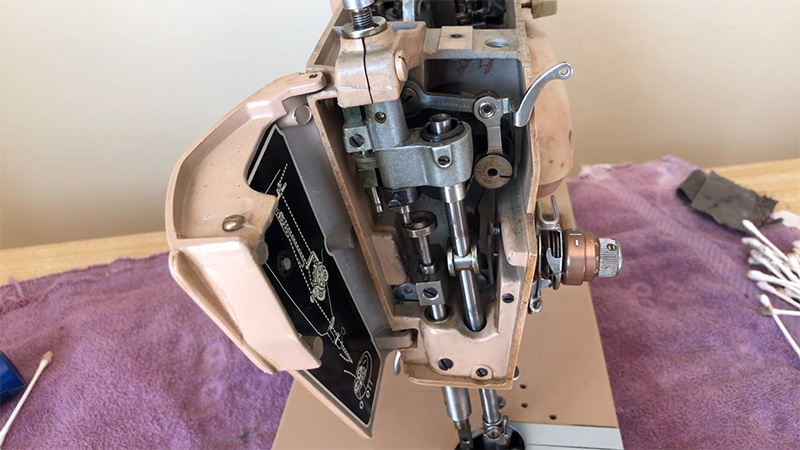

Remove the Needle Plate or Access Cover

Locate the needle plate or access cover on your sewing machine. It’s often secured with one or two screws.

Use a screwdriver to carefully remove these screws and lift off the plate or cover. Be sure to keep track of the screws, so you can easily reassemble everything later.

Access the Feed Dogs

With the needle plate or cover removed, you’ll have a clear view of the feed dogs. These are the metal teeth that move up and down to advance the fabric. Take a moment to inspect the feed dogs to see how much lint and debris have accumulated.

Brush and Remove Lint

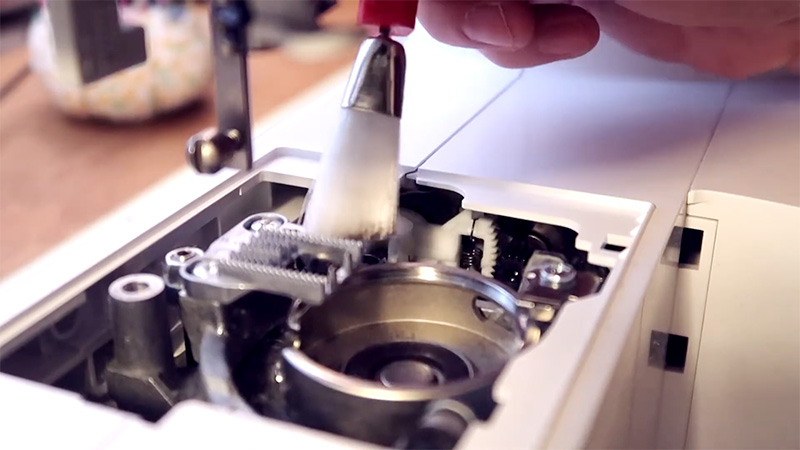

Use a lint brush or tweezers to gently remove lint, dust, and any other debris from the feed dogs. Work carefully to avoid scratching or damaging these sensitive components. Be thorough, especially in the areas between the teeth and around the edges.

Wipe Clean

After brushing away most of the lint and debris, use a soft cloth or a Q-tip slightly moistened with water to wipe down the feed dogs.

This step helps ensure that you’ve removed all the remaining residue and that the feed dogs are entirely clean. Be cautious not to leave any fibers or moisture behind, as this could attract more lint.

Lubricate

Consult your sewing machine’s manual to determine if your feed dogs require lubrication. If recommended, apply a small amount of sewing machine oil as per the manual’s instructions.

Typically, a drop or two of oil on each feed dog is sufficient. This lubrication helps the feed dogs move smoothly and prevents excessive friction.

Reassemble

Carefully reattach the needle plate or access cover that you removed in step 2. Secure it in place by reinserting and tightening the screws. Ensure that it’s properly aligned and seated to prevent any gaps or misalignment.

Test Your Machine

Before you continue with your sewing projects, plug in your machine, lower the presser foot, and run a few test stitches on a scrap piece of fabric to confirm that the feed dogs are functioning smoothly and the fabric is advancing properly.

This step allows you to verify that your cleaning and maintenance have restored the feed dogs to their optimal working condition.

Why Is It Necessary to Keep the Machine Clean and Lubricated?

Keeping your sewing machine clean and properly lubricated is vital for maintaining its functionality and extending its lifespan.

Whether you’re a professional seamstress or an occasional hobbyist, here are some compelling reasons why it’s necessary to keep your sewing machine clean and lubricated:

Prevents Wear and Tear

Regular use of your sewing machine causes friction between its moving parts. Without proper lubrication, this friction can lead to increased wear and tear on critical components like the motor, gears, and shafts.

Over time, this wear can compromise the machine’s performance and lead to costly repairs.

Improves Stitch Quality

Adequate lubrication ensures that the machine’s moving parts operate smoothly. When parts are well-lubricated, there’s less resistance, which contributes to more consistent and even stitches.

Without lubrication, you may experience skipped stitches, tension issues, and uneven stitch quality.

Reduces Noise

A clean and well-lubricated sewing machine runs quietly. The noise reduction not only makes sewing more pleasant but also indicates that the machine is operating smoothly. A noisy machine may be a sign that it requires maintenance.

Extends Machine Lifespan

Sewing machines can be a significant investment, and proper maintenance can significantly extend their lifespan.

A well-maintained machine can last for many years, offering good value for your investment.

Prevents Thread Breakage

Lack of lubrication can lead to excessive friction on the thread as it passes through the machine. This can result in thread breakage and frustration during your sewing projects. Properly lubricated machine parts reduce this friction and ensure a smoother thread path.

Reduces Heat Buildup

Sewing machines generate heat when they’re in use. Without lubrication, this heat can build up in critical components, potentially damaging them. Proper lubrication dissipates heat, protecting the machine from overheating.

Prevents Rust and Corrosion

Sewing machines are often made of metal, and metal parts can corrode when exposed to moisture.

Cleaning and lubricating your machine helps protect it from rust, especially if it’s stored in a humid environment or if you accidentally spill liquids on it.

Minimizes Repairs and Downtime

Regular maintenance, including cleaning and lubrication, can prevent many common sewing machine issues.

This means fewer trips to the repair shop and less downtime when you have important sewing projects to complete.

Safety Considerations

Over time, dust and lint can accumulate in your machine, potentially becoming a fire hazard. Proper cleaning helps eliminate this risk, ensuring your safety while sewing.

Saves Money

By investing a little time and effort in keeping your machine clean and lubricated, you can save money in the long run.

Preventative maintenance is much less expensive than repairs or, in the worst case, replacing your sewing machine.

FAQS

What is the importance of sewing?

Sewing is important for creating and repairing clothing, home decor, and other fabric items. It’s a valuable skill that allows for self-expression, customization, and cost-saving.

Why is the sewing machine important?

Sewing machines significantly speed up the sewing process, making it more efficient and precise. They are indispensable tools for both beginners and experienced sewers.

What is a sewing machine cleaner?

A sewing machine cleaner is a product designed to remove lint, dust, and debris from a sewing machine’s interior and exterior, ensuring smooth operation and prolonging its lifespan.

Where can I find sewing machine cleaners and supplies?

Sewing machine cleaners and supplies can be found at fabric and craft stores, online sewing retailers, and in the sewing machine accessories section of many department stores. They are also available through e-commerce websites like Amazon and eBay.

Last Words

The importance of cleaning lint from your sewing machine cannot be overstated. Regular maintenance is not merely a matter of aesthetics but a critical aspect of sewing machine care.

It safeguards the quality of your stitches, prevents thread jams, and maintains the efficiency of your machine.

Furthermore, cleaning lint reduces the risk of fire hazards, extends your machine’s lifespan, and ultimately saves you from expensive repairs.

Just as a seamstress takes care to select the finest fabrics and thread, they must also take the time to preserve the integrity of their sewing machine.

By doing so, they ensure that their sewing experience remains a smooth, enjoyable, and safe journey.

Leave a Reply