A silicone mold is a useful tool for creating complex shapes and forms, but it can be frustrating if the mold becomes sticky and difficult to use.

There are several reasons why a silicone mold may become sticky, including improper curing, cleaning, and preparation of the mold, as well as issues with the material being cast in the mold and the way the mold is stored and handled.

In this article, we will explore some of the common causes of sticky silicone molds and provide some tips for preventing and addressing this issue.

Silicone Mold and its Usage

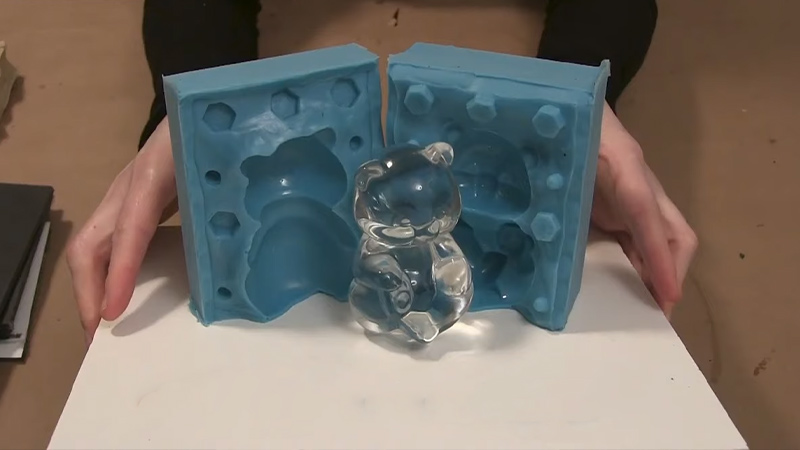

Silicone mold is a popular tool used by crafters, artisans, and cooks for creating a variety of shapes and forms. It is made from silicone rubber, which is known for its flexibility and durability.

What is silicone mold:

Silicone mold is a rubber material tool that can be used to cast a wide range of materials, including liquid soap, wax, plaster, low-melting metals, and more. It is also widely used in the kitchen for shaping ice, dough, chocolate, and other foods.

Uses of silicone mold:

Silicone mold has many uses, including creating jewelry, candles, soap, and other crafts. In the kitchen, silicone molds are used for making ice cubes, chocolate, and other food items. Silicone mold can also be used for casting metal and other materials in the construction and manufacturing industries.

Benefits of silicone mold:

Silicone mold offers several benefits over other materials used for making molds. It is flexible and can be easily bent or twisted without breaking, making it easy to remove the cast object from the mold. It is also durable and can withstand high temperatures, making it ideal for casting materials such as metal or resin. Silicone mold is also easy to clean and maintain, making it a convenient and versatile tool for many applications.

Why is My Silicone Mold Still Sticky?

There could be several reasons why your silicone mold is still sticky. Some possible reasons include: the mold was not properly cured before use, the mold was not properly cleaned before use, the mold was not properly prepared with a release agent, the material being cast in the mold was not properly prepared, the material being cast in the mold being at the wrong temperature, the mold was not allowed to cool properly, the mold was not stored properly, the mold was damaged or deformed, the mold was not made from high-quality silicone, or the mold was not made according to the recommended specifications. To prevent your silicone mold from becoming sticky, it is important to follow the instructions provided by the manufacturer and take proper care of the mold.

- The mold was not properly cured before use. Silicone molds need to be cured before they can be used, which involves baking the mold in the oven for a certain amount of time at a specific temperature. If the mold was not cured properly, it may remain sticky.

- The mold was not properly cleaned before use. Silicone molds should be washed with soap and water and allowed to dry completely before use. Any debris or residue on the mold can cause it to remain sticky.

- The mold was not properly prepared with a release agent. Before using a silicone mold, it should be sprayed with a release agent such as cooking spray or mold release wax. This helps to prevent the material being cast in the mold from sticking to the mold.

- The material being cast in the mold was not properly prepared. The material being cast in the mold, such as resin or clay, should be mixed and prepared according to the instructions provided. If the material is not properly prepared, it can cause the mold to remain sticky.

- The material being cast in the mold was not a t proper temperature. If the material cast in the mold is too cold, it can cause the silicone mold to become sticky. It is important to allow the material to have to the recommended temperature before casting it in the mold.

- The mold was not allowed to cool properly. After casting the material in the mold, the mold should be allowed to cool completely before attempting to remove the cast object. If the mold is not allowed to cool properly, it can cause the mold to remain sticky.

- The mold was not stored properly. Silicone molds should be stored in a cool, dry place away from direct sunlight. Exposure to heat or moisture can cause silicone molds to become sticky.

- The mold was damaged or deformed. If the silicone mold is damaged or deformed, it can cause the mold to become sticky. This can happen if the mold is dropped or subjected to excessive force.

- The mold was not made from high-quality silicone. If the silicone mold is not made from high-quality silicone, it can be more prone to becoming sticky. It is important to use silicone molds that are made from high-quality, food-grade silicone.

- The mold was not made according to the recommended specifications. If the silicone mold was not made according to the recommended specifications, it can cause the mold to remain sticky. This can happen if the mold was not made with the correct thickness or if it was not properly cured during the manufacturing process.

How Do You Make Silicone Molds Not Sticky?

If your silicone molds are becoming sticky and difficult to use, there are several steps you can take to prevent this issue and make them easier to clean and maintain. One method is to use the oven to help remove any sticky residue from the silicone molds.

To do this, heat the oven to 350 degrees Fahrenheit and place the silicone molds inside for 10 minutes. This will help to loosen any sticky residue and make the molds easier to clean. In addition to using the oven, you can also try washing the silicone molds with soap and water, drying them thoroughly, and applying a mold release agent such as cooking spray or mold release wax before use.

By following these steps, you can prevent your silicone molds from becoming sticky and ensure that they last for a long time.

How Do You Make Silicone Mold?

Creating a silicone mold is a simple process that involves mixing a silicone caulk with a catalyzing solution, applying the mixture to a mold frame, and allowing it to cure. Here are the steps to follow to make your own silicone mold:

- Make a catalyzing solution by mixing a high concentration of dish soap with water in a bowl. This will act as a catalyst for the silicone, allowing it to cure properly.

- Cut off the tip of the silicone caulk tube and set it in a caulking gun. This will make it easier to apply silicone to the mold frame.

- Prepare the silicone by mixing it with the catalyzing solution in the bowl. Stir the mixture until it is well combined.

- Apply the silicone mixture to the mold frame, using the caulking gun to evenly distribute the silicone. Make sure the mold is water-tight by filling any gaps or seams with more silicone.

- Allow the silicone to cure according to the manufacturer’s instructions. This typically involves letting the mold sit at room temperature for 24 to 48 hours.

- Once the silicone has cured, carefully remove the mold from the frame and wash it with soap and water to remove any excess silicone. Your silicone mold is now ready to use!

Important Note

One important note to keep in mind when using silicone molds is that they need to be properly cured before use. Curing involves baking the mold in the oven for a certain amount of time at a specific temperature.

This process helps to harden the silicone and prevent it from becoming sticky. If the silicone mold is not properly cured before use, it may remain sticky and difficult to work with. It is also important to clean the silicone mold thoroughly with soap and water before use and to apply a mold release agent.

Such as cooking spray or mold-release wax to prevent the material being cast in the mold from sticking to the mold. By following these steps, you can prevent your silicone molds from becoming sticky and ensure that they last for a long time.

Conclusion

Silicone molds are a useful tool for creating complex shapes and forms, but they can become sticky if not properly cared for.

Common causes of sticky silicone molds include improper curing, cleaning, and preparation of the mold, as well as issues with the material being cast in the mold and the way the mold is stored and handled.

To prevent your silicone molds from becoming sticky, it is important to follow the instructions provided by the manufacturer and take proper care of the mold. This includes curing the mold before use, cleaning it thoroughly, and applying a mold release agent before casting material in the mold.

By following these steps, you can ensure that your silicone molds remain in good condition and continue to provide reliable and consistent results.

Leave a Reply