The sewing machine drive belt is the unsung hero of every stitch, silently powering the needle’s rhythmic dance. Yet, it’s not impervious to wear and tear.

Understanding why a sewing machine drives belt stalls is crucial for any avid seamstress or tailor.

This mechanical marvel, connecting the motor’s force to the machine’s intricate mechanisms, can face a range of challenges.

From tension issues to misalignment, wear over time to obstructions, each factor plays a role in the belt’s performance.

Delving into the reasons behind a stalling drive belt equips us with the knowledge to troubleshoot, maintain, and ensure our trusty sewing companions continue their seamless creations.

What Is a Sewing Machine Drive Belt?

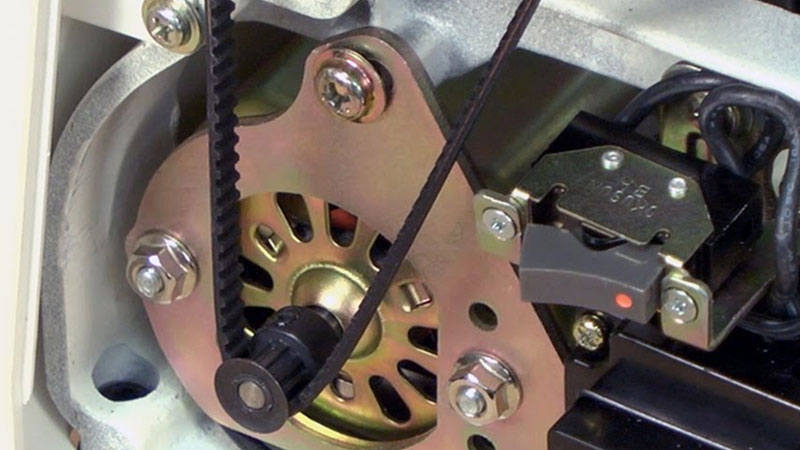

A sewing machine drive belt is a vital component that transmits power from the motor to various mechanical parts of the sewing machine.

Typically made of materials like rubber or synthetic compounds, it loops around the machine’s motor pulley and the handwheel, creating a connection that drives the needle, bobbin, and other critical components.

As the motor engages, it rotates the pulley, which, in turn, moves the drive belt. This rotational motion is then transferred to the machine’s mechanical systems, enabling the seamless operation of the sewing process.

Proper tension and alignment of the drive belt are essential for smooth and efficient sewing, making it a fundamental element in any functional sewing machine.

Why Sewing Machine Drive Belt Stalls?

A sewing machine drive belt plays a crucial role in the functionality of a sewing machine. It connects the motor to the machine’s mechanisms, enabling the needle and other components to move smoothly.

However, like any other mechanical part, sewing machine drive belts can sometimes stall or fail to function properly.

Several reasons can contribute to this issue:

Worn-out or Damaged Belt

Over time, the drive belt can deteriorate due to constant flexing, friction, and exposure to environmental elements.

This wear and tear can lead to cracks, fraying, or even complete breakage. It’s essential to regularly inspect the belt for any signs of damage and replace it if necessary to ensure smooth operation.

Loose Tension

Achieving the correct tension in a sewing machine’s drive belt is crucial. If it’s too loose, the belt won’t grip the pulleys effectively, leading to slippage or stalling.

Adjusting the tension to the manufacturer’s recommended specifications can prevent this issue.

Belt Misalignment

Proper alignment ensures that the belt maintains a consistent grip on the pulleys. If the belt is not correctly positioned, it can lead to uneven movement, causing the machine to stall.

Aligning the belt with the pulleys and other components is essential for seamless operation.

Debris and Obstructions

Dust, lint, and other debris can accumulate around the belt and pulleys, creating friction and hindering smooth movement.

Regular cleaning and maintenance, including removing any build-up around the belt, can prevent this issue.

Motor Issues

The motor provides the power needed to drive the sewing machine. If it’s not functioning correctly, it can put strain on the belt and cause stalling.

Motor problems might include overheating, insufficient power output, or mechanical failures.

Belt Tension Adjustment

Incorrect tension adjustment is a common cause of belt-related issues. If the tension is too high, it can strain the motor and other components, leading to stalling.

Conversely, if it’s too low, the belt may not grip the pulleys effectively, causing slippage.

Age of the Machine

Older machines may have drive belts made from materials that degrade over time. Vintage belts, often made of leather or early rubber compounds, can become brittle or weak.

Replacing these with modern, high-quality belts can significantly improve performance.

Improper Lubrication

Adequate lubrication is essential for reducing friction in a sewing machine’s moving parts.

When parts are not properly lubricated, it can increase resistance, making it harder for the belt to move smoothly.

Belt Stretching

Rubber belts, in particular, can stretch over time, causing a loss of tension. This stretching can lead to slippage and stalling.

Regular checks and adjustments for belt tension are necessary, especially with rubber belts.

Treadle Machine Issues

Treadle sewing machines operate using a foot pedal mechanism. If this mechanism becomes misaligned, damaged, or obstructed, it can interfere with the movement of the drive belt, leading to stalling.

Symptoms of Sewing Machine Drive Belt Stalling

When a sewing machine drive belt is experiencing issues or stalling, it exhibits several noticeable symptoms.

These indicators serve as warnings that there might be a problem with the belt or its associated components.

Here are the common symptoms of a stalling sewing machine drive belt:

Sluggish or Uneven Stitching

If you notice that your sewing machine is sewing slowly or the stitches appear uneven, it may be an indication of a stalling drive belt.

The inconsistent movement can lead to these sewing issues.

Unusual Noises

A drive belt that’s struggling to move smoothly can produce unusual noises, such as squeaking, squealing, or grinding sounds. These noises may indicate friction and slipping.

Machine Stops Abruptly

If your sewing machine stops suddenly and unexpectedly during operation, it could be due to the drive belt stalling.

The abrupt halt is a clear sign that something is impeding the belt’s movement.

Needle Jamming

Frequent needle jams or thread breakages can be a result of the drive belt stalling. When the belt doesn’t provide consistent power, it can lead to interruptions in the sewing process.

Visible Slippage

In some cases, you may be able to see the drive belt slipping or struggling to grip the pulleys.

This can often be observed if you remove the machine’s cover and manually turn the handwheel.

Inconsistent Handwheel Movement

When you turn the handwheel manually, it should move smoothly and consistently. If you feel resistance, uneven motion, or it’s hard to turn, it may be due to belt stalling.

Belt Damage or Wear

Inspect the drive belt for visible signs of damage, such as cracks, fraying, or excessive wear.

These physical indications suggest that the belt may be stalling or on the verge of failure.

Treadle Machine Sluggishness

For treadle sewing machines, if you’re using a foot pedal and notice that it’s becoming more challenging to maintain a consistent rhythm or pressure, it could be related to drive belt issues.

How Can You Fix Your Sewing Machine Drive Belt if It Stalls?

If your sewing machine drive belt is stalling, you may be able to address the issue with some basic troubleshooting and maintenance.

Here’s a step-by-step guide on how to fix a stalling sewing machine drive belt:

Turn off the Machine

Before attempting any repairs, ensure the sewing machine is turned off and unplugged from the power source for safety.

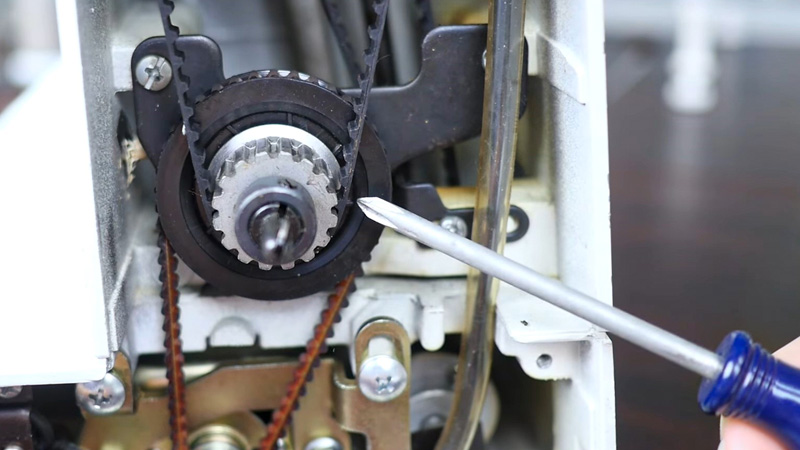

Inspect the Belt

Check the drive belt for signs of wear, damage, or misalignment. Look for cracks, fraying, or any areas where the belt seems compromised.

Clean the Belt and Pulleys

Use a clean, lint-free cloth or a small brush to remove any dust, lint, or debris from both the belt and the pulleys. This helps reduce friction and improves the grip.

Adjust Belt Tension

Refer to your sewing machine’s manual for instructions on how to adjust the belt tension.

In most cases, there will be a mechanism for tightening or loosening the belt. Ensure it is within the manufacturer’s recommended specifications.

Realign the Belt

Make sure the drive belt is properly aligned with the pulleys. If it’s off-center or not sitting correctly, gently adjust it to the correct position.

Check for Obstructions

Inspect the area around the belt and pulleys for any objects or threads that might be obstructing its movement. Remove any obstructions you find.

Lubricate Moving Parts

Apply a small amount of sewing machine oil to the moving parts, including the pulleys and any joints or hinges. This helps reduce friction and ensures smoother operation.

Test the Machine

Turn on the sewing machine and run it at a slow speed to see if the belt is now functioning properly. Observe for any signs of stalling or unusual noises.

Monitor Belt Performance

Keep an eye on the belt’s performance over the next few sewing sessions. If you notice any further issues, repeat the steps or consider seeking professional assistance.

Consider Replacement

If the belt is severely worn, damaged, or continues to stall despite your efforts, it may be necessary to replace it.

Refer to your sewing machine’s manual for guidance on purchasing the correct replacement belt.

How Can You Prevent Your Sewing Machine Drive Belt From Stalling?

Preventing your sewing machine drive belt from stalling involves regular maintenance and proper care.

By following these preventive measures, you can extend the life of your drive belt and ensure that your sewing machine operates smoothly:

Regular Cleaning

Clean the drive belt and the surrounding areas regularly to remove dust, lint, and debris that can accumulate and cause friction. A clean belt is less likely to slip or stall.

Lubrication

Keep the moving parts of your sewing machine well-lubricated as specified in the manufacturer’s manual. Lubrication reduces friction and helps the belt move smoothly.

Proper Tension Adjustment

Ensure that the drive belt is correctly tensioned according to the manufacturer’s recommendations.

Over-tightening or under-tightening can lead to stalling. Adjust the tension as needed.

Align the Belt

Check that the drive belt is properly aligned with the motor pulley and other components. Misalignment can cause uneven movement and stalling.

Inspect for Damage

Regularly inspect the drive belt for signs of wear, cracks, fraying, or other damage. If you notice any issues, address them promptly by repairing or replacing the belt.

Avoid Overloading

Avoid overloading your sewing machine with thick or heavy materials that can put excessive strain on the drive belt. Use appropriate needles and thread for the task at hand.

Smooth Operation

Operate the sewing machine smoothly and avoid sudden starts and stops, which can strain the belt. Gradual acceleration and deceleration are better for the drive belt’s longevity.

Use Quality Belts

When replacing the drive belt, opt for high-quality belts made from durable materials. Cheap or low-quality belts are more likely to wear out quickly.

Regular Maintenance Schedule

Create a maintenance schedule that includes cleaning, lubrication, and belt inspection.

Regularly perform these tasks to catch and address any issues before they become major problems.

Store Properly

When not in use, cover your sewing machine to protect it from dust and humidity.

Storing it in a clean and dry environment can prevent belt issues caused by environmental factors.

Professional Servicing

Periodically, have your sewing machine professionally serviced by a qualified technician.

They can perform more in-depth maintenance and check for potential issues that may not be visible during routine inspections.

FAQs

Why does my sewing machine’s drive belt keep slipping or stalling?

The drive belt may slip or stall due to factors like incorrect tension, misalignment, wear and tear, or obstructions. Regular maintenance can address these issues.

Can I fix a stalling drive belt on my own, or do I need professional help?

Basic troubleshooting like cleaning, lubricating, and adjusting tension can often resolve minor issues. However, if problems persist, it’s advisable to consult a professional technician.

How frequently should I inspect and maintain my sewing machine’s drive belt?

Regular maintenance, including cleaning and inspection, should be conducted every few months or more often if the machine is heavily used.

Is it possible to prevent drive belt stalling altogether?

Yes, regular cleaning, proper tension adjustment, and avoiding overloading the machine can significantly reduce the risk of drive belt stalling.

When should I consider replacing my sewing machine’s drive belt?

If the belt shows signs of severe wear, or damage, or continues to stall despite maintenance efforts, it’s recommended to replace it.

To Wrap Up

In the intricate dance of a sewing machine, the drive belt plays a pivotal role, translating motor power into precise stitches.

As we unravel the reasons behind a stalling drive belt, it becomes evident that regular maintenance and vigilant care are paramount.

From tension adjustments to proper alignment, each factor contributes to the belt’s reliable performance.

By understanding these intricacies, we empower ourselves to diagnose and rectify issues, ensuring our sewing machines remain steadfast allies in the world of fabric artistry.

With a well-maintained drive belt, the symphony of stitches continues to flow seamlessly, creating garments that bear the mark of craftsmanship and dedication.

Leave a Reply