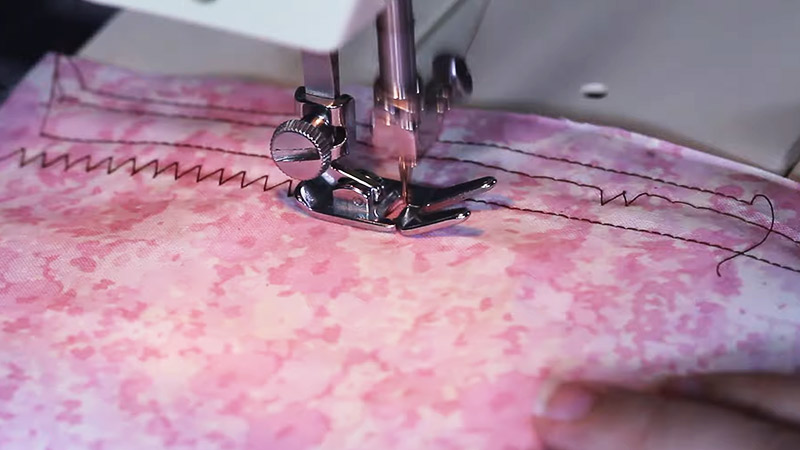

Make sure you have the right equipment before beginning your project – from a zigzag stitch machine to a bobbin and bobbin plate. Clean out any lint under the bobbins, replace the bobbin and bobbin plate if necessary, and test your zigzag stitch to ensure accuracy.

Before making any permanent changes to your curtains, be sure to consult with an expert first. When it comes time for replacements or repairs, know how to do it yourself so that you can save money in the long run.

Why Won’t My Sewing Machine Zigzag?

Make sure you have the right equipment. Clean out any lint under the bobbin and replace the bobbin and bobbin plate if necessary. Test your zigzag stitch by stitching a few inches away from one edge, then moving to another spot and doing it again.

Generate stitches evenly spaced along your project’s length using even pressure on your needle, making sure each stitch is tight against the fabric.

Why my zig-zag stitch is sewing straight?

If your zigzag stitch is sewing straight, there may be a simple solution. If the upper thread appears as a single line, the lower thread is incorrectly threaded.

To resolve this issue correctly install the lower thread by following the steps below: 1) Check to make sure that you are using the correct tension on both threads – if not, adjust it appropriately; and Follow these instructions to install the lower thread correctly: Hold one end of the lower thread with your left hand while pulling up on upper thread with your right hand in a Z-shaped motion.

Make sure that you hold onto both ends ofthelowerthread at all times so that it does not get tangled or kinked during installation.

What tension should my sewing machine be on for zig-zag stitch?

If you’re new to zigzag stitching, start with a lower tension setting and adjust as needed. When sewing on a bias fabric or one that is prone to shifting, use a higher tension so the stitches stay in place.

For delicate fabrics like lace, opt for a lighter thread weight (lower number) when stitching with a zigzag stitch to prevent snags and pulls. Remember: The higher your machine’s speed, the greater the risk of skipped stitches or puckers – go slowly and test your work frequently until you get it just right.

Experiment with different tensions until you find what works best for you; there are no hard-and-fast rules.

What tension setting should my sewing machine be on?

If you’re new to sewing, start off with the lowest tension setting and work your way up as needed. For more complex fabrics or seams, use a higher tension so that stitches will be stronger and less likely to break.

Avoid using too much pressure when sewn – this can cause damage to fabrics and machines alike. Be sure to check your machine’s ‘tension’ dial regularly in order for it not to wear out prematurely from overuse of one particular setting.

How do you turn a corner into a zigzag stitch?

To turn a corner into a zigzag stitch, start at one end and position the fabric so that the right side of the stitch falls just to the right of where you drew it on your paper.

Zigzag down the line until you get to your corner. For even more detail, try this: hold your drawn line parallel with both edges of your fabric before beginning zigzag stitching—this will help keep stitches evenly spaced along the length of your seamline and make for neater corners.

Don’t forget about reverse bias. When working in rounds or spirals, be sure to backstitch at each junction point (just above and below each new round). This will secure all layers together – preventing them from slipping while you work – and give your project a finished look. Keep things simple by using basic stitches like straight lines or half-double crochet when making corners in most fabrics; these are easy enough for beginners but still look professional once they’re finished.

And lastly…have fun with it. A bit of whimsy never hurt anyone ;).

How do you adjust the tension on a bobbin?

To adjust the tension on a bobbin, turn the tiny screw on the bobbin case a smidgen clockwise to tighten and counterclockwise to loosen. A quarter turn or less is usually the good starting point for adjusting your bobbin tension.

If the bobbin case doesn’t budge, it may be too tight – try turning the screw a smidgen more for increased tension or less for decreased tension. Keep in mind that over-tightening your bobbins can damage them and increase sewing time; under-tensioning can cause skipped stitches (and frustration).

Make sure you have all of your supplies before beginning: ruler, seam ripper, pins etc., so you don’t end up with frustrated sewn seams.

Is a higher number tighter tension?

Keeping the upper thread tension at a higher number will result in a tighter weave, while a lower number will produce a looser weave. You can adjust the upper thread tension on your machine by changing the dial to one unit up or down from its default setting.

When you’re adjusting the tension, remember that higher numbers indicate tighter tensions and lower numbers represent looser tensions. Changing the upper thread tension on your sewing machine can make for an even more precise seam. Tension” is key when it comes to accurate seams- so be sure to keep it adjusted according to the manufacturer’s guidelines.

What causes a sewing machine to skip stitches?

If your machine is skipping stitches, the first thing to check is the needle. If the needle isn’t bent or dull, you may need to replace it. You can find a new sewing machine needle at most retail stores or online retailers.

Make sure that you have the correct size and type of replacement needle before starting your project. Don’t forget to test drive the new needle before using it on your sewing project.

Frequently Asked Questions

Why does the thread bunch up underneath?

If you’re having trouble getting your thread bunching up underneath your fabric, make sure that your upper thread tension is adjusted.

Why isn my zig-zag stitch not working?

If the zigzag stitch doesn’t work, try one of the following: Remove the bobbin plate using a screwdriver and then remove the bobbin. Clean out any lint that may be under the bobbin and which may cause your zigzag stitch not to work. replaced the Bobbin and/or Bobbin Plate

How does a zig zag sewing machine work?

To create a zigzag stitch, the machine’s needle is controlled by a cam. This motion creates the zigzag stitch by moving the fabric in one direction while continuing to move the fabric in another direction.

What does increasing tension on sewing machine do?

Sewing machine tension is how tight the threads are pulled as you sew. The tighter your thread (or the higher your tension), the tighter your stitches. With proper tension, your sewing machine needle moves up and down, the bobbin thread is pulled up, and you get nice, neat, even stitches.

How do you fix thread tension?

If the tension isn’t perfect, adjust the bobbin spring. If the needle thread shows on top of the under layer and on one side of the stitching, loosen it; if the stitch appears balanced without showing on either layer, tighten it. Make another test seam and examine stitches for balance.

To Recap

There are a few potential causes for your sewing machine not zigzagging, so it is important to troubleshoot the issue and fix it if possible. Broken needle bars can cause your machine to not sew properly, while dirty or clogged needles can also prevent the fabric from moving through the machine correctly. Sometimes simply cleaning and lubricating your sewing machine will solve the problem. In cases where fixing the issue isn’t possible, you may need to purchase a new sewing machine.

Leave a Reply